Badge Printer Machine Producer

About badge printer machine producer

Where to Find Badge Printer Machine Producers?

China remains the central hub for badge printer machine manufacturing, with key industrial clusters in Henan, Shandong, and Guangdong provinces driving innovation and export capacity. Henan's digital printing ecosystem, particularly around Zhengzhou, hosts advanced producers specializing in UV flatbed and 3D badge printing systems, supported by integrated supply chains for printheads, ink formulations, and control electronics. Shandong’s Yancheng and Qingdao regions focus on mechanical badge press machines, leveraging local metalworking expertise for durable, cost-efficient manual and semi-automatic models.

These regional hubs offer vertically aligned production networks—enabling rapid prototyping, component sourcing, and assembly within compact geographic zones. Buyers benefit from scalable output, with lead times averaging 15–30 days for standard units and 35–45 days for customized configurations. Cost efficiencies stem from localized material access and streamlined logistics, delivering 20–35% lower unit prices compared to equivalent Western or Southeast Asian suppliers. The concentration of technical talent and mature export infrastructure supports both high-volume procurement and niche customization demands.

How to Choose Badge Printer Machine Suppliers?

Selecting reliable producers requires a structured evaluation of technical, operational, and transactional performance indicators:

Technical Capability Verification

Confirm compatibility with target substrates (e.g., fabric, plastic, metal) and printing technologies (UV inkjet, heat transfer, manual pressing). For digital systems, verify specifications such as print width (ranging from 30cm to 130cm), printhead type (Epson, Ricoh, Toshiba), and ink compatibility (eco-solvent, UV, DTF). Mechanical badge producers should demonstrate die-cutting precision, mold durability, and consistent lamination quality.

Production Infrastructure Assessment

Evaluate supplier capacity through objective metrics:

- Facility size and dedicated R&D teams for product iteration

- In-house engineering support for customization (software integration, dual-head setups, automation upgrades)

- Monthly output capacity and inventory turnover rates

Cross-reference online revenue data and reorder rates as proxies for market acceptance and reliability. Prioritize suppliers with documented response times ≤3 hours and on-time delivery rates exceeding 95%.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE, RoHS) are not explicitly listed in available data, buyers should request compliance documentation prior to order placement. Utilize secure payment mechanisms with milestone-based releases, ideally tied to pre-shipment inspection reports. Conduct sample testing to assess print resolution, color accuracy, adhesion strength, and mechanical consistency—particularly for high-volume or mission-critical applications.

What Are the Best Badge Printer Machine Producers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range (Sets) | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Henan Yindu Digital Co.,Ltd | Henan, CN | UV Flatbed, 3D Badge Printers | US $890,000+ | 98% | ≤3h | 28% | 5 | $1,000–$5,800 |

| Zhengzhou Audley Digital Control Equipments Co., Ltd. | Henan, CN | Digital Heat Transfer, UV Inkjet | US $410,000+ | 92% | ≤2h | 27% | 5 | $300–$9,700 |

| Shenzhen Suntech Digital Equipment Co., Ltd. | Guangdong, CN | Large-Format 3D UV Printers | US $490,000+ | 100% | ≤2h | 33% | 4 | $4,600–$25,600 |

| Shandong Sena Printing Group Co., Ltd. | Shandong, CN | UV Flatbed, Desktop Printers | US $50,000+ | 100% | ≤2h | 27% | 5 | $1,350–$4,550 |

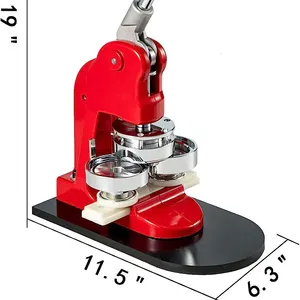

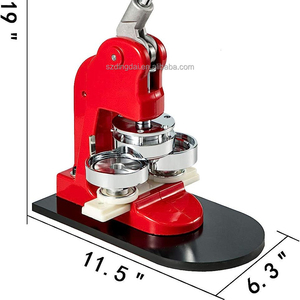

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Shandong, CN | Manual Badge Press Machines | US $120,000+ | 100% | ≤3h | 18% | 5 | $39–$280 |

Performance Analysis

Henan Yindu Digital leads in volume and capability, offering a broad range of UV and 3D printing solutions with strong after-sales engagement (28% reorder rate). Shenzhen Suntech stands out for premium large-format systems, commanding higher price points while maintaining perfect on-time delivery and the highest customer retention (33% reorder rate). Zhengzhou Audley provides wide configurability across print widths and ink types, suitable for specialized textile and signage applications.

For budget-conscious buyers, Yancheng Stik Pro offers entry-level mechanical badge machines at highly competitive prices, ideal for small businesses or promotional product vendors. Shandong Sena balances affordability with digital printing functionality, targeting startups and mid-tier operations. All top-tier suppliers support customization—including software integration, heating systems, and multi-material processing—though detailed technical consultation is recommended before finalizing specifications.

FAQs

How to verify badge printer machine producer reliability?

Assess responsiveness, historical delivery performance, and transaction volume. Request proof of compliance with international electrical and safety standards. Validate claims through third-party inspection services and demand functional video demonstrations of equipment operation.

What is the typical minimum order quantity (MOQ)?

Most suppliers list MOQs of 1 set or 1 carton, enabling low-risk sampling. Bulk pricing typically applies at 5+ units. Custom configurations may require higher MOQs depending on tooling or software development needs.

What customization options are commonly available?

Digital printers support adjustments in print width, printhead configuration, ink type, and software interface. Mechanical badge machines can be modified for different button diameters (25mm–58mm), shape dies (round, square), and manual/semi-automatic operation modes.

Do suppliers provide technical support and training?

Leading producers offer remote setup assistance, user manuals, and troubleshooting guides. Some provide on-site technician deployment or video tutorials for machine calibration and maintenance, especially for high-end UV and flatbed systems.

What are the shipping and logistics considerations?

Machines are typically shipped FOB from major ports (Qingdao, Shanghai, Shenzhen). Air freight is viable for samples (7–10 days); sea freight is cost-effective for full container loads (20–35 days). Ensure proper packaging and insurance coverage for sensitive electronic components.