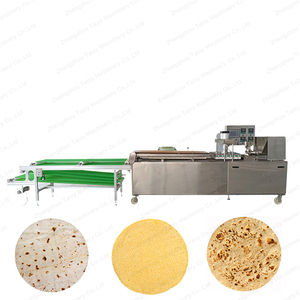

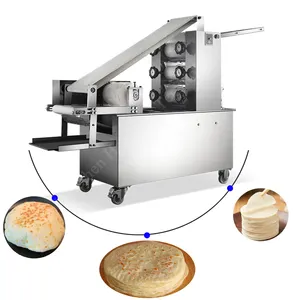

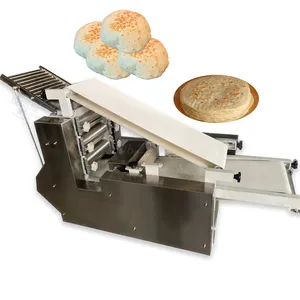

Bajaj Automatic Roti Maker

About bajaj automatic roti maker

Where to Find Bajaj Automatic Roti Maker Suppliers?

China remains the central hub for automated food processing equipment manufacturing, with key supplier clusters concentrated in Guangdong and Henan provinces. Guangzhou-based manufacturers leverage proximity to port infrastructure and a mature ecosystem of electronics and appliance component suppliers, enabling rapid assembly of electromechanical kitchen systems. Meanwhile, Zhengzhou has emerged as a core production zone for commercial-grade flatbread machinery, supported by regional specialization in grain processing equipment and industrial automation.

These geographic clusters offer integrated supply chains—spanning servo motors, heating elements, and stainless steel fabrication—that reduce component lead times by 20–30%. Suppliers in these regions typically operate vertically consolidated facilities capable of end-to-end production, from sheet metal stamping to final testing. Buyers benefit from scalable output, with standard delivery windows averaging 25–40 days for containerized orders. Cost efficiencies are notable, with production expenses 18–25% below those of equivalent EU- or India-based manufacturers due to localized sourcing and energy-optimized manufacturing layouts.

How to Choose Bajaj Automatic Roti Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and transactional security:

Technical & Quality Verification

Confirm adherence to international electrical safety standards such as CE or IEC 60335. For markets requiring regulatory compliance (EU, GCC, North America), demand valid test reports for thermal control systems, motor insulation, and structural durability. Request documentation on material specifications—particularly food-grade aluminum or non-stick coating certifications—for contact surfaces.

Production Capacity Assessment

Evaluate operational scale through verifiable metrics:

- Minimum factory footprint of 1,000m² for sustained batch production

- In-house engineering teams supporting customization (e.g., voltage adaptation, diameter adjustment)

- Integrated quality control checkpoints including pre-shipment burn-in testing

Cross-reference declared capabilities with on-time delivery performance (target ≥98%) and reorder rates (>15% indicates post-sale satisfaction).

Transaction Risk Mitigation

Utilize secure payment frameworks such as escrow services that release funds upon shipment verification. Prioritize suppliers enrolled in verified trade assurance programs with documented dispute resolution histories. Conduct sample evaluations focusing on cycle consistency, dough handling accuracy, and surface browning uniformity before scaling orders.

What Are the Best Bajaj Automatic Roti Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Guangzhou Tianyin International Trade Co., Ltd. | Guangdong, CN | Other Snack Machines (52) | US $80,000+ | 100% | ≤4h | 27% | $420–450 | 1 piece |

| Shanghai Seny Machinery Co., Ltd. | Shanghai, CN | Other Snack Machines (676) | US $80,000+ | 100% | ≤4h | 16% | $10,780–15,730 | 1 set |

| Zhengzhou Younker Import & Export Co., Ltd. | Henan, CN | Other Snack Machines (406) | US $30,000+ | 100% | ≤1h | <15% | $980–3,966 | 1 set |

| Zhengzhou Delta Machinery Co., Ltd. | Henan, CN | Grain Product Making Machines (122) | - | 100% | ≤5h | - | $1,900–2,300 | 1 set |

| Zhengzhou Taizy Trading Co., Ltd. | Henan, CN | Grain Product Making Machines (122) | US $20,000+ | 100% | ≤3h | 20% | $1,200–16,500 | 1 set |

Performance Analysis

Guangzhou Tianyin stands out for competitive pricing and high reorder frequency (27%), indicating strong customer retention for entry-level units. Shanghai Seny offers large-scale snack equipment integration but at significantly higher price points, targeting institutional clients. Zhengzhou Younker leads in responsiveness (≤1h average reply time) and mid-range commercial solutions, though its lower reorder rate suggests room for post-sale engagement improvement. Zhengzhou-based suppliers dominate technical specialization in roti and flatbread systems, with multiple vendors offering configurable parameters such as thickness, temperature range, and throughput speed (up to 60 pieces/hour). All listed suppliers maintain perfect on-time delivery records, underscoring reliable logistics execution across the sector.

FAQs

How to verify bajaj automatic roti maker supplier reliability?

Validate certifications (CE, ISO) through official registries and request product-specific test data, including power consumption, heating cycle stability, and mechanical endurance logs. Analyze buyer feedback focused on after-sales service, spare parts availability, and controller firmware performance.

What is the typical sampling timeline?

Standard sample production takes 10–18 days, depending on customization level. Shipment via express courier adds 5–7 business days internationally. Complex adaptations (e.g., dual-voltage operation or non-standard diameter molds) may extend development to 25 days.

Can suppliers ship globally?

Yes, all major suppliers support worldwide shipping under FOB, CIF, or DAP terms. Confirm compliance with destination country electrical codes and import regulations for food-contact appliances. Sea freight is recommended for multi-unit orders to optimize per-unit logistics costs.

Do manufacturers provide free samples?

Sample policies vary: some suppliers offset costs against future bulk orders (e.g., credit upon 5+ unit purchase), while others charge full production cost. Expect sample fees ranging from 30–70% of unit price, recoverable only if contractual volume thresholds are met.

How to initiate customization requests?

Submit detailed specifications including desired output capacity, input voltage (110V/220V), dough thickness range, and material finish preferences. Leading suppliers provide CAD drawings or 3D models within 72 hours and can deliver functional prototypes within 3–4 weeks for validation.