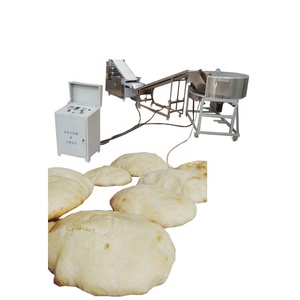

Auto Roti Maker

Top sponsor listing

Top sponsor listing

About auto roti maker

Where to Find Auto Roti Maker Suppliers?

China remains the central hub for auto roti maker manufacturing, with key production clusters concentrated in Henan and Guangdong provinces. Henan, in particular, has emerged as a dominant region for food processing machinery, hosting specialized suppliers with vertically integrated facilities capable of producing fully automated chapati, paratha, and pita bread systems. These industrial ecosystems benefit from proximity to raw material suppliers, CNC fabrication workshops, and logistics networks, enabling efficient scaling for both small-batch and bulk export orders.

The supply chain advantages translate into competitive pricing and shorter lead times—typically 25–40 days for standard configurations. Localized manufacturing reduces component procurement cycles by up to 30%, while established export channels support global distribution. Buyers gain access to diverse machine types, including countertop models for commercial kitchens and high-capacity rotary systems for industrial bakeries. The region’s focus on grain-based food equipment ensures deep technical expertise in dough handling, temperature control, and non-stick baking surfaces.

How to Choose Auto Roti Maker Suppliers?

Procurement decisions should be guided by objective evaluation criteria to ensure performance, compliance, and supply chain reliability:

Technical Capability Assessment

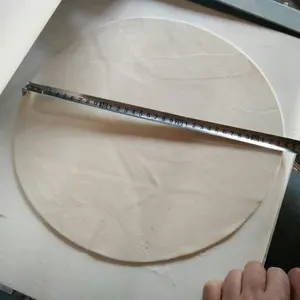

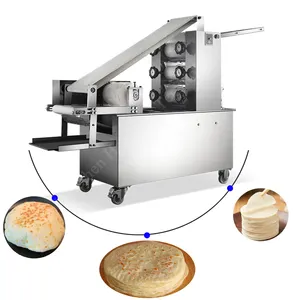

Verify that suppliers offer documented specifications covering power rating (typically 1900W–3000W), production capacity (ranging from 600–3,000 rotis/hour), and material compliance. Critical construction materials should include food-grade stainless steel (SS304 preferred) and Teflon-coated or ceramic non-stick heating plates. Confirm availability of motor-driven rolling and pressing mechanisms for consistent thickness control.

Production & Customization Capacity

Evaluate suppliers based on:

- In-house engineering teams capable of modifying belt speed, mold shape, and automation level

- Customization options for voltage (110V/220V), plug type, and language interface

- Ability to adjust output diameter (15–30 cm typical), thickness (1–5 mm), and yield per hour

Cross-reference product listings with customization tags such as "food-grade mold," "high-yield automation," and "multi-shape design" to identify technically flexible partners.

Quality & Transaction Reliability

Prioritize suppliers demonstrating verifiable performance metrics:

- On-time delivery rate ≥98%

- Response time ≤3 hours

- Reorder rate below 20% indicating stable customer satisfaction

- Online transaction volume exceeding US $100,000 annually

While formal ISO 9001 certification is not universally listed, consistent on-time delivery and low dispute rates serve as practical proxies for quality management maturity.

What Are the Best Auto Roti Maker Suppliers?

| Company Name | Main Products (Listings) | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|

| Jiangmen Kinbo Electric Industrial Co., Ltd. | Electric Grills & Griddles (389) | $395+ (bulk) | 500 pcs | 100% | ≤1h | $3,000+ | Color, material, size, logo, packaging, graphic |

| Ningbo Yinzhou Baiying International Trading Co., Ltd. | Canister Vacuums (57) | $293.27/set | 300 pcs | 100% | ≤6h | $20,000+ | Limited |

| Adan Trading Inc | Balers (742) | $2,200–8,800/set | 1 set | Not specified | ≤2h | Not specified | Shape, size, capacity, automation |

| Saidashi Machinery (Henan) Co., Ltd. | Grain Product Making Machines (407) | $401–1,980/set | 1 set | 100% | ≤3h | $100,000+ | Size, shape, thickness, noise, packaging |

| Jiaozuo Dingchang Machinery Equipment Co., Ltd. | Grain Product Making Machines (197) | $350–8,800/set | 1 set | 100% | ≤2h | $130,000+ | Belt speed, mold, color, shape, dimensions, cooling, logo |

Performance Analysis

Jiaozuo Dingchang Machinery leads in customization depth, offering over 15 configurable parameters including automation level and cooling systems, supported by strong online sales volume. Saidashi Machinery and Jiangmen Kinbo demonstrate high reliability with 100% on-time delivery and sub-3-hour response times, ideal for time-sensitive procurement. Adan Trading and Jiaozuo Dingchang list premium industrial units priced above $5,000, targeting large-scale bakery operations requiring continuous throughput. Suppliers based in Henan exhibit stronger specialization in food machinery, correlating with higher technical adaptability and after-sales support consistency.

FAQs

What certifications should auto roti maker suppliers have?

While not all suppliers list ISO or CE certifications, prioritize those providing evidence of electrical safety testing and food-contact material compliance. For EU and North American markets, CE marking and RoHS documentation are essential for customs clearance and retail distribution.

What is the typical MOQ for auto roti makers?

MOQ varies significantly: trading companies often require 300–500 units for batch orders, while direct machinery manufacturers accept single-set purchases for trial runs. Industrial-grade models typically ship one unit per order due to size and customization complexity.

How long does production and shipping take?

Lead time averages 25–35 days for manufacturing, plus 15–30 days for sea freight depending on destination. Air shipping reduces transit to 5–10 days but increases costs by 200–300%. Expedited production (within 15 days) is possible with confirmed down payments and simplified configurations.

Do suppliers offer OEM/ODM services?

Yes, multiple suppliers—including Jiangmen Kinbo and Jiaozuo Dingchang—explicitly support OEM branding, custom molds, and packaging design. Minimum order thresholds for full OEM integration typically start at 500 units or equivalent revenue commitment.

How to verify machine performance before ordering?

Request video demonstrations of live operation, including dough feeding, rolling, baking cycle timing, and output consistency. Ask for sample production reports showing hourly yield, power consumption, and defect rates. Where feasible, arrange third-party inspection services (e.g., SGS, Bureau Veritas) prior to shipment to validate build quality and safety standards.