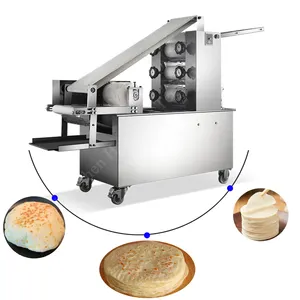

Auto Chapati Maker

About auto chapati maker

Where to Find Auto Chapati Maker Suppliers?

China leads global production of automated food processing equipment, with key manufacturing clusters in Guangdong, Hebei, and Zhejiang provinces. These regions host vertically integrated supply chains for electromechanical components, heating elements, and food-grade stainless steel, enabling cost-efficient production of auto chapati makers. Shenzhen and Yiwu serve as innovation and export hubs, combining compact design engineering with scalable assembly lines tailored for both household and commercial models.

Suppliers leverage localized access to CNC machining, die-casting, and sheet metal fabrication to reduce component lead times by 25–40% compared to offshore manufacturers. Industrial ecosystems support rapid prototyping and batch customization, allowing buyers to source units ranging from small-scale countertop models ($5–$20) to fully automatic commercial systems ($1,500–$5,000). Average production capacity among mid-tier suppliers exceeds 500 units per month, with delivery windows typically between 15–30 days for standard orders.

How to Choose Auto Chapati Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify adherence to international electrical safety standards (IEC 60335), particularly for heating and motor control systems. CE or RoHS certification is essential for EU market entry, while UL listing may be required for North American distribution. Request test reports on temperature regulation accuracy, dough thickness consistency, and cycle time performance (typically 8–15 seconds per chapati).

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area of 2,000m² for sustained volume output

- In-house tooling and mold-making capabilities for faster iteration

- Integration of PLC-based control systems and servo-driven rolling mechanisms

Cross-reference listed product ranges with specialization metrics—suppliers listing over 1,000 grain processing machines demonstrate domain expertise and R&D continuity.

Transaction Reliability Indicators

Prioritize suppliers with verifiable on-time delivery rates above 90% and response times under 2 hours. Reorder rates below 20% may indicate niche positioning or limited scalability, whereas rates above 22% suggest consistent customer satisfaction. Confirm packaging durability for international shipping and assess warranty terms covering motor, heating plate, and control board components.

What Are the Best Auto Chapati Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| LUOHE GOLDEN SHELL MECHANICAL EQUIPMENT CO.,LTD | Henan, CN | Grain Product Making Machines | $550,000+ | 91% | ≤2h | 20% | $800–1,350 | 1 set |

| Shenzhen Hanbeter Technology Co., Ltd. | Guangdong, CN | Grain Product Making Machines (1,694) | $150,000+ | 92% | ≤1h | 22% | $360–1,980 | 1 piece/set |

| Longyao Tongruida Special Equipment Factory | Hebei, CN | Grain Product Making Machines (1,001) | $60,000+ | 100% | ≤1h | <15% | $500–1,500 | 1 piece |

| Yiwu Aikelansi Electrical Appliance Co., Ltd. | Zhejiang, CN | Customization Available | $70,000+ | 100% | ≤5h | <15% | $4.67–19.39 | 2–16 pieces |

| Adan Trading Inc | Fujian, CN | Grain Product Making Machines (295) | Not available | Not available | ≤2h | Not available | $2,200–5,300 | 1 set |

Performance Analysis

LUOHE GOLDEN SHELL demonstrates strong industrial capacity with high revenue volume and competitive pricing for commercial-grade units. Shenzhen Hanbeter stands out for technical specialization, supported by a broad listing portfolio and fast response cycles. Longyao Tongruida achieves perfect on-time delivery, indicating disciplined logistics management despite lower reorder frequency. Yiwu Aikelansi offers the lowest entry price point with flexible MOQs, ideal for trial orders or retail testing. Adan Trading Inc targets premium segments with high-cost, large-scale systems but lacks transparency in performance metrics, increasing due diligence requirements.

FAQs

How to verify auto chapati maker supplier reliability?

Cross-check claimed certifications with official databases. Request evidence of quality control processes, including incoming material inspection, in-process testing, and final product validation. Analyze transaction history via verified revenue indicators and buyer feedback focused on machine durability and after-sales service responsiveness.

What is the typical sampling timeline?

Standard sample production takes 7–14 days, depending on customization level. Fully assembled functional units are usually shipped within 10 days after payment confirmation. Air freight delivery to most international destinations requires an additional 5–8 days.

Can suppliers accommodate custom voltage or plug types?

Yes, most established manufacturers support dual-voltage configurations (110V/220V) and regional plug adaptations (Type C, I, G). Custom PCB programming for temperature control and cycle timing is also commonly offered upon request.

Do suppliers provide free samples?

Free samples are rare for high-value machinery. Buyers typically pay full sample cost plus shipping, which may be partially refunded upon placement of a bulk order. Sample fees range from 1.5x to 2x the unit price in mass production.

How to initiate customization requests?

Submit detailed specifications including desired output capacity (chapatis/hour), power requirements, material grade (e.g., SUS304 rollers), and interface language for digital displays. Reputable suppliers will respond with engineering drawings, BOM breakdowns, and prototype timelines within 3–5 business days.