Bar Ice Maker

CN

CN

CN

CN

About bar ice maker

Where to Find Bar Ice Maker Suppliers?

China remains the global epicenter for commercial ice maker manufacturing, with key production clusters in Guangdong, Shandong, and Shanghai driving innovation and cost efficiency. Dongguan and Guangzhou in Guangdong province host a dense network of refrigeration equipment manufacturers specializing in compact, high-efficiency bar ice makers tailored for hospitality environments. These regions benefit from mature supply chains for compressors, evaporators, and food-grade stainless steel, reducing component lead times by 20–30% compared to offshore alternatives.

Shanghai and Shandong facilities focus on scalable industrial designs, integrating advanced cooling technologies such as air-cooled condensers and Danfoss compressors. Proximity to major ports like Qingdao and Nansha enables efficient containerized shipping, with average export processing times under 10 days. The ecosystem supports both standardized models (50–300kg/24h output) and engineered solutions for integrated bar systems, including all-in-one units with storage bins and dispensers. Buyers gain access to vertically integrated production lines capable of delivering orders within 30–45 days, with customization options spanning voltage compatibility (110V–220V), phase configuration (single/three-phase), and material finishes.

How to Choose Bar Ice Maker Suppliers?

Procurement decisions should be guided by structured evaluation criteria to ensure technical reliability and transaction security.

Technical & Quality Compliance

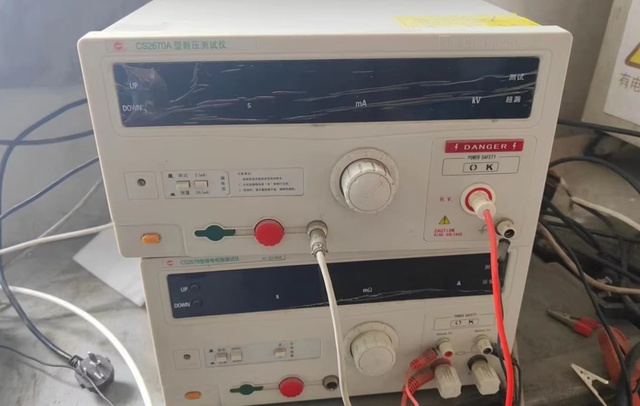

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For commercial deployment in North America or Europe, confirm electrical compliance with local grid specifications (e.g., 110V/60Hz or 220V/50Hz). Prioritize suppliers offering third-party test reports for noise levels (ideally ≤45 dB), energy consumption, and daily ice yield accuracy. Units designed for continuous operation should feature corrosion-resistant materials (SUS304 stainless steel) and self-diagnostic control systems.

Production Capability Assessment

Evaluate supplier infrastructure based on the following indicators:

- Minimum factory area exceeding 3,000m² for stable batch production

- In-house engineering teams supporting OEM/ODM configurations

- Integrated assembly lines covering refrigeration system welding, insulation, and final testing

Cross-reference online transaction volume and reorder rates—suppliers with >30% repeat order rates demonstrate consistent product performance and service reliability.

Transaction & Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Request sample units to validate build quality, cycle time, and ice clarity before scaling procurement. Confirm packaging specifications (wooden crates for sea freight, reinforced cartons for air) and insurance coverage during transit. Analyze response times (<2 hours preferred) and language proficiency to ensure smooth communication throughout the sourcing lifecycle.

What Are the Best Bar Ice Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization |

|---|---|---|---|---|---|---|---|

| Dongguan Lanxin Refrigeration Equipment Co., Ltd. | Guangdong, CN | Ice Machines, Refrigeration Equipment, Drink Dispensers | US $1,000+ | 100% | ≤2h | 33% | No |

| Guangzhou Huli Catering Equipment Co., Ltd. | Guangdong, CN | Ice Makers, Sealing Machines, Freezers | US $8,000+ | 100% | ≤3h | 33% | No |

| Shanghai Icema Refrigeration Technology Co., Ltd. | Shanghai, CN | Custom Ice Machines, Cold Rooms, Chillers | US $1,400,000+ | 95% | ≤2h | 24% | Yes |

| Shandong Yinuo Refrigeration Engineering Co., Ltd. | Shandong, CN | Tubular Ice Machines, Industrial Systems | US $200,000+ | 87% | ≤2h | 66% | No |

| Huzhou Bingmai Catering Equipment Co., Ltd. | Zhejiang, CN | Commercial Ice Makers, Worktop Units | US $20,000+ | 90% | ≤1h | <15% | Yes |

Performance Analysis

Dongguan Lanxin and Guangzhou Huli demonstrate strong operational consistency with 100% on-time delivery, making them reliable for standard bar ice maker procurement. Shanghai Icema stands out for customization depth—offering tailored control systems, solar-compatible compressors, and multi-language interfaces—despite a lower reorder rate, indicating potential gaps in post-sale follow-up. Shandong Yinuo leads in customer retention (66% reorder rate), suggesting robust product durability in high-throughput environments. Huzhou Bingmai offers the fastest response time (≤1h), advantageous for time-sensitive negotiations. Buyers seeking OEM branding or specialized voltage configurations should prioritize suppliers with documented customization capabilities and in-house technical teams.

FAQs

How to verify bar ice maker supplier reliability?

Validate certifications through official registries and request factory audit reports or video tours. Analyze transaction history, focusing on consistent on-time delivery (>90%) and verifiable customer feedback regarding compressor longevity and after-sales support.

What is the typical lead time for bar ice maker orders?

Standard units require 25–35 days for production and pre-shipment inspection. Custom configurations may extend lead times to 45–60 days, depending on design complexity and component availability.

Can suppliers provide samples for quality testing?

Yes, most suppliers offer sample units at full or partial cost. Samples typically ship within 7–14 days after payment and can be used to evaluate ice formation speed, water efficiency, and operational noise.

What are common customization options?

Available modifications include voltage and phase adjustments, bin capacity integration, color finishes, logo printing, and control panel language selection. High-end suppliers support full OEM branding and PLC-based automation systems.

What logistics options are available for international shipping?

Suppliers generally offer FOB, CIF, and DDP terms. Sea freight is optimal for full-container loads, while air shipping suits urgent sample deliveries. Ensure proper packaging and marine insurance for long-haul shipments.