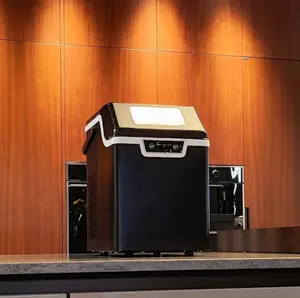

Built In Bar Ice Maker

About built in bar ice maker

Where to Find Built-in Bar Ice Maker Suppliers?

China remains the dominant manufacturing hub for built-in bar ice makers, with key production clusters concentrated in Shanghai, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains encompassing compressor fabrication, stainless steel stamping, and electronic control assembly, enabling efficient production cycles. Shanghai-based suppliers benefit from proximity to international ports and advanced R&D infrastructure, facilitating rapid prototyping and export logistics. Cixi in Zhejiang Province is recognized for its specialization in compact refrigeration appliances, hosting over 200 manufacturers with expertise in small-scale ice-making systems.

The industrial ecosystem supports both high-volume OEM/ODM production and customized engineering solutions. Facilities typically integrate CNC machining, automated welding, and environmental testing chambers to ensure product reliability under continuous operation. Average monthly output per supplier ranges from 1,000 to 5,000 units, depending on factory scale and automation level. This concentration enables buyers to achieve cost efficiencies of 20–35% compared to domestic sourcing in North America or Europe, particularly for commercial-grade models requiring robust cooling performance and corrosion-resistant materials.

How to Choose Built-in Bar Ice Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Quality Assurance & Compliance

Verify adherence to international standards such as CE, RoHS, and ISO 9001. For commercial applications, confirm compliance with food safety regulations (e.g., NSF certification where applicable). Request test reports for compressor endurance, condensation management, and energy efficiency under sustained load conditions. Suppliers should provide documentation for critical components including compressors (e.g., Secop, Embraco), evaporators, and control boards.

Production & Engineering Capacity

Assess core capabilities through the following indicators:

- Minimum facility size of 3,000m² for scalable production

- In-house design teams supporting custom voltage (110V/220V), dimensional configurations, and branding (logo, color, packaging)

- On-site testing protocols for leakage, vibration, and thermal cycling

Cross-reference online revenue data and reorder rates to validate market acceptance and post-sale reliability.

Procurement & Risk Mitigation

Utilize secure payment mechanisms such as escrow services for initial orders. Prioritize suppliers with ≤5-hour average response times and on-time delivery rates exceeding 97%. Conduct sample validation to assess build quality, noise levels (measured in dB), and ice production consistency before scaling procurement. Confirm packaging suitability for long-haul shipping, especially for stainless steel units vulnerable to moisture damage.

What Are the Best Built-in Bar Ice Maker Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Main Product Focus | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

| Shanghai Chuangli Refrigeration Equipment Co., Ltd. | Shanghai, CN | US $15,000,000+ | 100% | 40% | ≤5h | Color, material, size, logo, packaging, graphic | Commercial built-in ice makers | 5 pieces/sets/cartons |

| Shanghai Sihao Machinery Equipment Co., Ltd. | Shanghai, CN | US $1,800,000+ | 98% | 17% | ≤4h | Color, size, output, material, logo, packaging, dimensions | Commercial cube ice makers | 1 piece/set |

| Shanghai Tolcat Industrial Co., Ltd. | Shanghai, CN | US $300,000+ | 99% | 20% | ≤2h | Limited customization reported | Commercial ice machines | 1 piece/cubic meter |

| Cixi Jirui Electric Appliance Co., Ltd. | Zhejiang, CN | US $3,000+ | 75% | <15% | ≤6h | Standard product variants only | Mini bar & restaurant ice makers | 2 pieces/cartons |

| Yuyao Haohong Electrical Appliance Co., Ltd. | Zhejiang, CN | US $180,000+ | 100% | <15% | ≤2h | No customization indicated | Countertop & portable ice makers | 1–100 pieces |

Performance Analysis

Shanghai Chuangli stands out with the highest reorder rate (40%) and verified full customization capabilities, indicating strong customer retention and engineering flexibility. Despite a higher MOQ, its 100% on-time delivery record and substantial revenue volume suggest robust logistics and quality control systems. Shanghai Sihao offers low MOQs (as low as 1 set) and broad customization scope, making it suitable for niche market entries or pilot batches. Yuyao Haohong provides entry-level pricing with minimal order thresholds but lacks customization support, positioning it for budget-focused retail channels. Suppliers based in Shanghai demonstrate superior responsiveness (≤5h avg.) and compliance readiness, while Zhejiang-based vendors offer competitive pricing at the expense of lower reorder metrics and delivery consistency.

FAQs

What are typical lead times for built-in bar ice makers?

Standard orders require 25–35 days from confirmation, including production and pre-shipment inspection. Customized units may extend lead times by 10–15 days, depending on design complexity and component availability.

Can suppliers accommodate dual-voltage (110V/220V) configurations?

Yes, multiple suppliers—including Shanghai Chuangli and Cixi Jirui—explicitly list 110V–240V compatibility as a standard or customizable feature, essential for global distribution.

Do built-in bar ice makers use air-cooled or water-cooled systems?

Air-cooled condensers are standard across the listed products, reducing installation complexity and water consumption. This design is optimal for bar and restaurant environments without direct water line access.

What materials are commonly used in construction?

Stainless steel (grades 304 or 201) is prevalent for external housing and internal components to resist corrosion and meet hygiene standards. Interior liners are typically food-grade ABS plastic with antimicrobial properties.

Is sample ordering recommended before bulk procurement?

Yes, sampling is critical to evaluate ice clarity, cycle time, noise level, and build quality. Most suppliers allow single-unit orders, though fees apply and shipping costs are typically borne by the buyer.