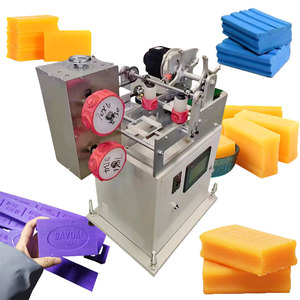

Bar Soap Making Machine

Top sponsor listing

Top sponsor listing

About bar soap making machine

Where to Find Bar Soap Making Machine Suppliers?

China remains the global hub for bar soap making machine manufacturing, with key industrial clusters concentrated in Henan and Zhejiang provinces. These regions host vertically integrated supply chains combining precision engineering, chemical processing, and packaging automation. Henan, home to over 40% of China’s soap machinery suppliers, benefits from established heavy industry infrastructure and proximity to raw material sources such as caustic soda and fatty acid derivatives. Zhejiang's coastal location enables efficient export logistics, particularly through Ningbo and Shanghai ports, reducing shipping lead times by 7–10 days compared to inland regions.

Suppliers in these zones operate within mature ecosystems where casting, CNC machining, assembly, and testing occur under one roof. This integration supports rapid prototyping and scalable production, with standard lead times averaging 25–40 days for fully automated lines. Buyers benefit from localized component sourcing—reducing costs by 18–25% versus Western manufacturers—and access to modular designs adaptable to batch or continuous production. The presence of specialized R&D centers further enhances innovation in energy-efficient heating systems, programmable logic control (PLC), and low-waste plodder technology.

How to Choose Bar Soap Making Machine Suppliers?

Procurement decisions should be guided by rigorous evaluation criteria focused on technical capability, quality assurance, and transactional reliability.

Technical & Production Capabilities

Assess suppliers based on equipment scope and engineering depth:

- Minimum factory area of 3,000m² for full-line production capacity

- In-house design teams capable of customizing molds, extrusion systems, and cutting mechanisms

- Integration of PLC/HMI controls, temperature regulation units, and hydraulic pressing systems

Verify offerings include complete turnkey solutions: mixing kettles, plodders, refrigerated cooling tunnels, stamping presses, and multi-axis cutters.

Quality Management Systems

Prioritize suppliers with ISO 9001 certification as a baseline for consistent output. For international buyers, CE marking is essential for compliance with EU safety directives. Request documentation on material traceability (e.g., stainless steel grade 304/316 for contact surfaces) and electrical system conformity (IEC 60204-1). Independent verification of performance claims—such as soap bar dimensional accuracy (±0.5mm tolerance) and production speed (up to 2,000 bars/hour)—should be conducted via video audit or sample testing.

Transaction Security & Service Metrics

Evaluate responsiveness and fulfillment reliability using verifiable metrics:

- On-time delivery rate ≥95%

- Average response time ≤3 hours

- Reorder rate above 20% indicating customer retention

Utilize third-party inspection services pre-shipment and consider escrow payment terms for initial large-volume orders.

What Are the Best Bar Soap Making Machine Suppliers?

| Company Name | Type | Main Products | Customization Options | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate | Sample Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Zhejiang Baoshijie Chemical Technology Co., Ltd. | Custom Manufacturer | Soap, Hand Wash, Laundry Detergent, Sanitizer | Color, shape, mold, weight, packaging, label, glycerin, TFM, essential oil, logo, graphic | 100% | ≤7h | $40,000+ | - | N/A |

| Henan Lovo Industry Co., Ltd. | Multispecialty Supplier | Bar Soap Machines, Laundry Soap Lines | Color, material, size, logo, packaging, label, graphic | 95% | ≤3h | $540,000+ | 23% | $1,000–$5,500 |

| Changge City Bainte Machinery Factory | Manufacturer | Soap Making Machines, Mixing & Packaging Equipment | Limited customization (size, capacity) | 100% | ≤2h | $700+ | - | $700–$18,000 |

| Henan Taion Industry Co., Ltd. | Manufacturer | Soap Making Machines, Filling & Wrapping Systems | Material, size, logo, packaging, labeling | 100% | ≤1h | $10,000+ | <15% | $3,000–$12,000 |

| Nantong Sting Co., Ltd. | Manufacturer | Complete Soap Production Lines, Sealing Machines | High customization potential (full line integration) | 100% | ≤3h | $320,000+ | 50% | $30,000–$133,300 |

Performance Analysis

Nantong Sting Co., Ltd. stands out with a 50% reorder rate and high-end production lines targeting large-scale operations, though entry-level pricing starts at $30,000. Henan Lovo offers mid-range automation with strong after-sales engagement (23% repeat order rate) and responsive communication. Changge City Bainte provides cost-effective entry points, including a $700 semi-automatic unit, ideal for startups or pilot production. Zhejiang Baoshijie differentiates through formulation expertise, enabling clients to co-develop specialty soaps alongside machinery procurement. Taion Industry excels in responsiveness (≤1h average reply) but shows lower customer retention, suggesting room for improvement in long-term support.

FAQs

How to verify bar soap making machine supplier reliability?

Cross-check ISO and CE certifications with accredited bodies. Request factory audit reports or video walkthroughs confirming CNC machining capabilities, welding standards, and final assembly processes. Analyze transaction history focusing on dispute resolution, delivery consistency, and post-installation technical support.

What is the typical lead time for soap machine production?

Standard configurations require 25–35 days from order confirmation. Customized turnkey lines may take 40–60 days depending on complexity. Add 10–20 days for international sea freight based on destination port congestion and customs clearance protocols.

Can suppliers accommodate custom soap formulations and shapes?

Yes, leading suppliers offer mold design services for custom bar dimensions, logos, and embossing. Some integrate formulation support for glycerin content adjustment, TFM optimization, and essential oil compatibility. Confirm material compatibility (e.g., corrosion-resistant alloys for acidic additives) during technical review.

Do manufacturers provide installation and training?

Most suppliers include remote commissioning support. On-site installation and operator training are typically available at additional cost ($1,500–$3,000 plus travel). Ensure service packages cover PLC programming guidance, maintenance schedules, and troubleshooting protocols.

What are common payment and sampling terms?

Standard payment terms include 30% advance, 70% before shipment. Sampling fees are often applied toward bulk orders. Entry-level machine samples start at $700, with full-line demonstrations arranged upon request. Escrow or Trade Assurance-backed transactions are recommended for first-time partnerships.