Batch Coders

1/23

1/23

1/26

1/26

1/3

1/3

1/16

1/16

1/14

1/14

1/3

1/3

1/3

1/3

1/18

1/18

1/3

1/3

0

0

1/28

1/28

1/30

1/30

1/15

1/15

0

0

1/3

1/3

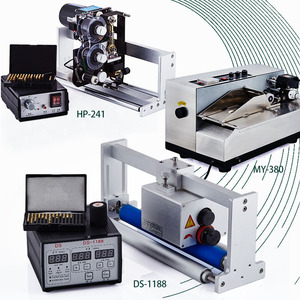

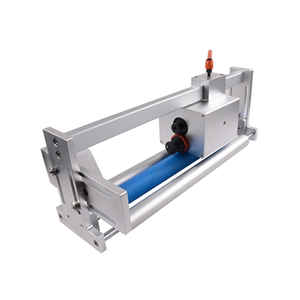

About batch coders

Where to Find Batch Coders Suppliers?

China remains the dominant hub for batch coder manufacturing, with key production clusters concentrated in Anhui, Fujian, and Henan provinces. These regions host vertically integrated facilities specializing in industrial coding equipment, supported by mature supply chains for ink systems, thermal print heads, and automation components. Hefei (Anhui) and Xiamen (Fujian) are recognized for precision engineering of hot-stamp and inkjet coders, while Zhengzhou (Henan) serves as a center for high-speed automatic coding systems used in food, pharmaceutical, and packaging industries.

The clustering enables streamlined access to component suppliers, reducing lead times and production costs by 15–25% compared to non-specialized regions. Suppliers benefit from localized availability of CNC machining, electrical assembly, and software integration services within 50km radii, allowing rapid prototyping and scalable output. Most manufacturers support direct export operations with established logistics partnerships, facilitating global distribution. Typical production cycles range from 15–30 days for standard models, with expedited delivery options available for low-complexity units.

How to Choose Batch Coder Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Quality Assurance

Verify adherence to international quality standards such as ISO 9001. For markets in Europe or North America, ensure CE marking compliance to meet regulatory requirements for electrical safety and electromagnetic compatibility. Request documentation on printhead durability, ink resistance testing, and environmental operating ranges (temperature/humidity tolerance).

Production and Customization Capability

Assess supplier capacity through objective indicators:

- Minimum factory area exceeding 2,000m² for sustained volume output

- In-house R&D teams capable of firmware customization and interface integration (e.g., PLC, HMI)

- On-site CNC, welding, and electronics assembly capabilities

Cross-reference these with customization tags—such as variable font size, QR/barcode generation, multi-language support, and material-specific ribbon formulation—to confirm technical flexibility.

Transaction Reliability Metrics

Prioritize suppliers demonstrating consistent performance: on-time delivery rates ≥95%, response times ≤4 hours, and reorder rates above 20%. Analyze verifiable transaction histories indicating annual online revenue exceeding US $100,000 as a proxy for market validation. Use third-party inspection services or video audits to validate claims before placing bulk orders.

What Are the Best Batch Coder Suppliers?

| Company Name | Location | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Min. Order Quantity |

|---|---|---|---|---|---|---|---|---|

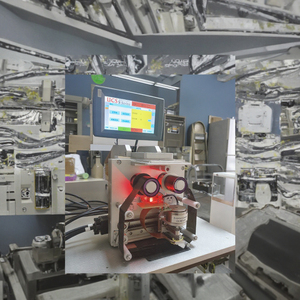

| Hefei Huahao Times Automation Technology Co., Ltd. | Anhui, CN | Custom Manufacturer | US $130,000+ | 93% | ≤3h | <15% | Ribbon length, color, logo, packaging, label, video demo | 1 piece/set |

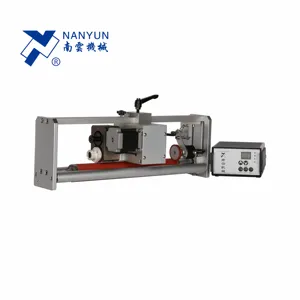

| Fujian Nan Yun Packing Machinery Co., Ltd. | Fujian, CN | Custom Manufacturer | US $130,000+ | 100% | ≤3h | 25% | Color, font size, ribbon width, laser marking, material, printer type, logo | 1 set |

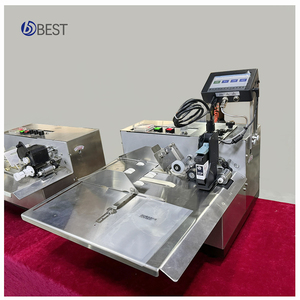

| Henan Best Packing Machine Co., Ltd. | Henan, CN | Multispecialty Supplier | US $220,000+ | 95% | ≤2h | 19% | QR code, digital upgrade, logo, graphic, packaging, material size | 1 piece/set |

| Xinxiang New Bell Information Materials Co., Ltd. | Henan, CN | Custom Manufacturer | US $100,000+ | 97% | ≤1h | <15% | Nozzle type, toner, conveyor integration, material, logo, graphic | 1 unit/set |

| Henan Union Coding Tech Co., Ltd. | Henan, CN | Custom Manufacturer | US $560,000+ | 98% | ≤4h | 21% | Printhead options, pneumatic systems, ribbon color, batch number format, bracket length, ink rolls | 1 set |

Performance Analysis

Fujian Nan Yun stands out with a perfect 100% on-time delivery rate and broad customization scope, including laser marking and multi-lane configurations. Henan Union Coding Tech demonstrates strong market confidence with the highest reported online revenue (US $560,000+) and a 98% delivery rate, indicating robust order management. Hefei Huahao and Xinxiang New Bell offer competitive entry-level pricing and fast response times (≤3h and ≤1h respectively), making them suitable for time-sensitive inquiries. Suppliers based in Henan collectively show strong responsiveness, with all three averaging sub-4-hour replies. For high-reliability contracts, prioritize partners with ≥97% on-time delivery and proven customization depth in ink formulation, code formatting, and integration with production lines.

FAQs

What certifications should batch coder suppliers have?

ISO 9001 is essential for quality system verification. CE certification is required for exports to Europe. Additional marks like RoHS may be necessary depending on material compliance needs. Always request copies of certificates and verify test reports for electrical components and fluid safety.

What is the typical MOQ and lead time?

Most suppliers list minimum order quantities of 1 piece or set, accommodating sample and small-batch procurement. Standard lead times range from 15–25 days after order confirmation. Complex customizations may extend this to 35 days. Air freight adds 7–10 days for international delivery.

Can batch coders be customized for specific production lines?

Yes, leading manufacturers offer integration-ready models with adjustable mounting brackets, conveyor synchronization, programmable logic controls (PLC), and remote diagnostics. Customization includes font styles, date formats (DD/MM/YYYY, MM/YY, etc.), QR/barcode generation, and language scripts.

Do suppliers provide product samples?

Sample policies vary. Some suppliers offer functional units at near-production cost, particularly for orders exceeding five units. Others may require full payment upfront, which can be partially credited upon subsequent bulk purchase.

How to evaluate long-term supplier reliability?

Analyze reorder rates (≥20% indicates customer satisfaction), on-time delivery consistency (≥95%), and response efficiency. Request references or case studies involving similar industry applications. Conduct virtual factory audits to assess production floor organization, inventory control, and quality inspection protocols.