Best Owc Machine

About best owc machine

Where to Find OWC Machine Suppliers?

The global supply base for OWC (Optimal Work Cycle) machines is concentrated in China, where industrial clusters in Zhejiang, Jiangsu, and Shandong provinces support specialized manufacturing ecosystems. These regions host vertically integrated facilities capable of producing precision components, control systems, and full assembly units under one roof. Zhejiang’s Taizhou and Wuxi zones are particularly notable for commercial-grade equipment production, with established supply chains for stainless steel (SS-304), CNC-machined parts, and automated drive systems.

Suppliers in these hubs benefit from proximity to raw material sources and logistics infrastructure, enabling cost efficiencies of 15–25% compared to Western manufacturers. The presence of mature subcontractor networks—spanning casting, welding, and electrical integration—allows for rapid prototyping and scalable production. Buyers can expect standard lead times of 30–45 days for containerized orders, with localized sourcing reducing both MOQ barriers and customization delays. Regional advantages include access to certified engineering teams, in-house R&D departments, and compliance-tested designs suitable for international markets.

How to Choose OWC Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to ISO 9001 quality management standards as a baseline. For export-oriented procurement, confirm CE marking or equivalent safety certifications applicable to destination markets. Request documentation on material specifications (e.g., SS-304 usage in wet environments), motor efficiency ratings, and PLC control system compatibility. Independent testing reports for durability, load capacity, and cycle performance should be available upon request.

Production Capability Assessment

Evaluate supplier infrastructure using the following criteria:

- Minimum factory area exceeding 2,000m² for sustained volume output

- In-house machining capabilities including CNC lathes, hydraulic presses, and welding stations

- Dedicated assembly lines with functional testing protocols per unit

Cross-reference claimed capacities with actual order history and on-time delivery metrics (target ≥97%).

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as third-party escrow services until post-delivery inspection is completed. Prioritize suppliers participating in verified trade assurance programs. Conduct pre-shipment inspections to validate build quality against agreed specifications. For critical applications, require sample testing under real-world conditions—benchmarking cycle stability, energy consumption, and maintenance intervals before scaling orders.

What Are the Best OWC Machine Suppliers?

| Company Name | Main Products | Key Equipment Types | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Quantity | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Taizhou Weiss Machinery Co., Ltd. | Commercial Laundry Equipment, Washing Machines | Mangle Ironing Machines, Commercial Washers | 100% | ≤2h | 25% | US $470,000+ | 1 set | $1,900–$7,000 |

| Wuxi Changan Machine Factory | Wire Mesh Making Machines, Barbed Wire Equipment | Automatic Barbed Wire Machines | 100% | ≤4h | - | US $30,000+ | 1 set | $3,200–$4,000 |

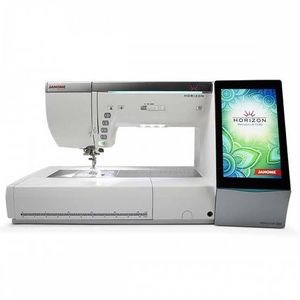

| MONOP LLC | Sewing Machines, Embroidery Machines | JANOME, Baby Lock Models | - | ≤7h | - | - | 1–2 units | $200–$650 |

| smartime solution | Tractors, Loaders, Excavators | Ride-on Orec Machines, Espresso Units | - | ≤2h | - | - | 1–2 pieces | $120–$1,800 |

| BEST GADGETS LLC | Smart Coffee Makers, Hand Tools | Fully Automatic Espresso Machines | - | ≤12h | - | - | 3 units | $150–$200 |

Performance Analysis

Taizhou Weiss Machinery stands out for verifiable performance metrics, including a 100% on-time delivery rate and strong after-sales engagement reflected in a 25% reorder rate. Its focus on commercial laundry systems indicates specialization in high-cycle mechanical design—relevant for OWC applications requiring repetitive motion reliability. Wuxi Changan Machine Factory demonstrates robust production discipline with full automation in barbed wire machinery, suggesting transferable expertise in continuous-operation equipment.

While MONOP LLC and smartime solution offer competitive pricing and fast response times, they lack published delivery and reorder data, increasing due diligence requirements. BEST GADGETS LLC presents low entry costs but mandates higher MOQs (3 units), which may limit flexibility for pilot testing. Suppliers with documented online revenue and consistent response times below 4 hours exhibit stronger operational maturity and customer service infrastructure.

FAQs

How to verify OWC machine supplier reliability?

Cross-validate ISO or CE certifications through official registries. Request facility audit reports or video walkthroughs of production lines. Analyze transaction histories for consistency in order fulfillment and responsiveness. Third-party inspection services can verify product conformity prior to shipment.

What is the typical sampling timeline for OWC machines?

Standard samples take 15–30 days to produce, depending on complexity. Custom configurations involving unique control panels or drive systems may require 40–50 days. Air freight adds 7–14 days for international delivery. Some suppliers waive sample fees for confirmed bulk orders (≥5 units).

Can OWC machine suppliers accommodate custom engineering requests?

Yes, many manufacturers support OEM/ODM projects. Submit detailed technical drawings, performance parameters, and material requirements. Leading suppliers provide 3D modeling previews within 72 hours and prototype iterations within 3–4 weeks. Confirm IP protection agreements before disclosure of proprietary designs.

What are common MOQ and pricing structures?

MOQs range from 1 set (for industrial models) to 2–3 units (consumer-grade). Prices vary significantly by application: commercial laundry systems start at $1,900/set, while automated barbed wire machines exceed $3,200/set. Bulk discounts typically apply at 5+ units, with negotiated terms improving at container-load volumes.

Do suppliers handle global shipping and customs clearance?

Established exporters manage FOB and CIF shipping globally. Confirm incoterms, packaging standards (export-worthy crates), and compliance with import regulations in your country. Sea freight is optimal for heavy machinery, while air shipping suits urgent sample deliveries.