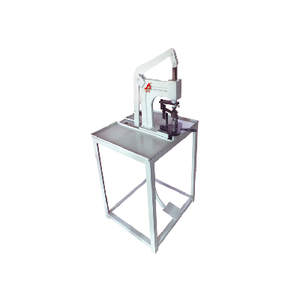

Best Button Machine

About best button machine

Where to Find Button Machine Suppliers?

China leads global production of button-making machinery, with concentrated manufacturing hubs in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable output for both manual and automated systems. Zhejiang and Jiangsu specialize in mid-to-high-end mechanical and pneumatic models, leveraging proximity to precision component suppliers and port logistics for efficient export. Shenzhen-based manufacturers focus on smart, digitally controlled equipment, integrating automation technologies into badge and garment button assembly lines.

The industrial clusters enable cost efficiencies through localized sourcing of dies, molds, and pressing mechanisms—reducing material procurement time by 25–40% compared to offshore alternatives. Buyers benefit from flexible production scales, with standard lead times averaging 15–30 days for stocked models. The ecosystem supports customization in die size (ranging from 25mm to 70mm), shape (round, square, rectangular), and drive type (manual, semi-automatic, servo-controlled). This infrastructure positions Chinese suppliers as primary sources for both small-batch craft producers and large-scale apparel manufacturers.

How to Choose Button Machine Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify machine compatibility with target applications—garment button attachment, snap fastener assembly, or promotional badge production. Confirm compliance with international safety standards such as CE or RoHS where applicable. Request documentation on load capacity, stroke frequency, and die alignment accuracy. For automated units, assess programmable logic controller (PLC) integration and fault diagnostics.

Production Capability Assessment

Evaluate core manufacturing indicators:

- Minimum factory area of 1,000m² indicating established operations

- In-house tooling and mold-making capabilities for custom die fabrication

- Dedicated R&D or engineering support for non-standard configurations

Cross-reference online revenue metrics and reorder rates (>30% preferred) as proxies for product reliability and customer satisfaction.

Procurement Safeguards

Utilize secure payment terms with milestone releases tied to shipment and post-arrival inspection. Prioritize suppliers offering sample testing—functional trials reduce risk of misalignment with fabric thickness or button diameter requirements. Analyze response time (≤6 hours ideal) and on-time delivery performance (≥97%) as indicators of operational discipline.

What Are the Best Button Machine Suppliers?

| Company Name | Location | Main Products (Listings) | On-Time Delivery | Reorder Rate | Avg. Response | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| HAO HANN ENTERPRISE CO., LTD. | Taiwan, CN | Button Making Machines (109) | 100% | 33% | ≤6h | $6,000+ | $2,300–4,500 | 1 set / pair |

| Jiangsu Enters Industrial Co., Ltd. | Jiangsu, CN | Button Making Machines (225) | 92% | <15% | ≤5h | $120,000+ | $399–550 | 1 set / piece |

| Myoung Intelligent Technology (Shenzhen) Co., Ltd. | Guangdong, CN | Button Making Machines (29) | 97% | 33% | ≤6h | $20,000+ | $69–330 | 1 piece |

| Longnan County Shengming Machinery Equipment Co., Ltd. | Jiangxi, CN | Sewing Machines (1361) | 100% | 50% | ≤3h | $30,000+ | $1,000–4,900 | 1–5 sets |

| Zhejiang Shengtian Machinery Co., Ltd. | Zhejiang, CN | Other Apparel Machines (95) | 100% | - | ≤22h | - | $230–1,500 | 1 set |

Performance Analysis

HAO HANN and Longnan Shengming demonstrate high reliability with 100% on-time delivery and strong reorder rates (33% and 50%, respectively), indicating consistent quality and service. Longnan stands out for its low response time (≤3h) and broad sewing machine expertise, making it a strategic partner for integrated garment hardware solutions. Jiangsu Enters offers competitive pricing and high listing volume but has a lower reorder rate, suggesting potential gaps in long-term customer retention. Myoung Intelligent provides entry-level pricing ideal for startups or niche badge production, though its smaller scale may limit customization depth. Zhejiang Shengtian delivers cost-effective pneumatic systems but lacks verified transaction data, warranting additional due diligence.

FAQs

How to verify button machine supplier reliability?

Cross-check declared certifications (CE, ISO) with official registries. Request evidence of quality control processes, including pre-shipment inspection reports and functional testing videos. Analyze buyer reviews focusing on durability under continuous operation and after-sales technical support responsiveness.

What is the typical sampling timeline?

Standard samples are typically shipped within 7–14 days. Customized units with unique dies or automation features require 20–30 days for configuration and testing. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate custom button sizes and shapes?

Yes, most established suppliers offer custom die fabrication. Provide technical drawings specifying diameter, height, and material thickness. Minimum order quantities for custom tooling typically start at 500–1,000 units per design.

Do manufacturers provide free samples?

Sample policies vary. Some suppliers waive fees for orders exceeding five units or when total procurement exceeds $5,000. Otherwise, expect to cover 30–60% of unit cost plus shipping.

What are standard MOQ and payment terms?

MOQ ranges from 1 piece (manual models) to 5 sets (industrial machines). Common payment terms include 30% deposit with balance before shipment. Escrow services are recommended for first-time transactions to mitigate delivery and quality risks.