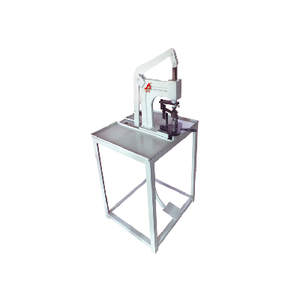

Best Button Maker Machine

About best button maker machine

Where to Find Button Maker Machine Suppliers?

China leads global production of button maker machines, with concentrated manufacturing hubs in Jiangsu, Guangdong, and Yancheng offering specialized capabilities. Jiangsu and Yancheng are key centers for precision engineering in garment accessory machinery, hosting vertically integrated facilities that produce from component casting to final assembly. These regions benefit from established supply chains for dies, molds, and pneumatic systems, reducing material procurement cycles by 20–30% compared to non-specialized zones.

The industrial clusters support both high-volume standard production and low-volume custom configurations. Manufacturers typically operate automated stamping lines and CNC machining centers, enabling batch outputs of 100–500 units per month depending on machine complexity. Buyers gain access to mature ecosystems where raw material sourcing, heat treatment, and quality inspection occur within tightly controlled geographic proximity, ensuring consistent throughput and traceability. Key advantages include competitive pricing (20–40% below Western OEMs), lead times averaging 15–30 days for stocked models, and flexibility for manual, semi-automatic, and fully automatic variants.

How to Choose Button Maker Machine Suppliers?

Adopt the following verification criteria when evaluating suppliers:

Technical Capability Assessment

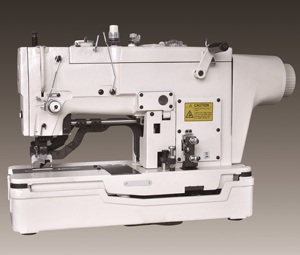

Confirm machine specifications align with intended use—manual presses for small-batch craft operations (e.g., 37x37mm to 70x25mm formats), rotary die systems for fridge magnets, and hydraulic models for metal snap buttons. Verify compatibility with common blank sizes (25mm, 38mm, 50mm, 63mm) and materials including plastic, metal, and composite substrates.

Production Infrastructure Review

Evaluate supplier capacity based on:

- Factory area supporting dedicated assembly lines

- In-house tooling and mold-making capabilities

- Integration of sealing, crimping, and pressure calibration stations

Cross-reference online revenue indicators and reorder rates (>20% suggests product reliability and service consistency). Prioritize suppliers with response times under 6 hours to ensure post-purchase technical support availability.

Transaction and Quality Assurance

Require documented quality control procedures, including pre-shipment testing for die alignment, pressure consistency, and structural durability. While formal ISO certification is not universally present, suppliers with on-time delivery rates exceeding 97% demonstrate operational discipline. Utilize secure payment mechanisms and request sample units to validate build quality before scaling orders.

What Are the Best Button Maker Machine Suppliers?

| Company Name | Main Products | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| HAO HANN ENTERPRISE CO., LTD. | Buttons, Button Making Machines, Garment Rivets | $2,300–3,700 | 1 set | 100% | ≤7h | 33% | US $9,000+ |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines, Heat Press Machine | $39–338 | 1 set | 100% | ≤3h | 17% | US $130,000+ |

| Jiangsu Enters Industrial Co., Ltd. | Button Making Machines, Sealing & Packaging Machines | $399–550 | 1 set | 91% | ≤4h | <15% | US $120,000+ |

| Myoung Intelligent Technology (Shenzhen) Co., Ltd. | Button Making Machines, DTF Printers, Heat Press | $69–330 | 1 piece | 97% | ≤6h | 24% | US $20,000+ |

| Guangzhou Fengear Technology Co., Ltd. | Button Making Machines, Sewing & Apparel Machines | $25.99–990 | 1 set / 10 sets | 100% | ≤3h | <15% | US $8,000+ |

Performance Analysis

HAO HANN ENTERPRISE CO., LTD. stands out with a 33% reorder rate and full on-time delivery record, indicating strong customer retention despite higher price points ($2,300–3,700), likely due to Taiwan-originated quality standards. Yancheng Stik Pro leads in volume readiness with the highest online revenue (US $130,000+) and sub-3-hour response times, ideal for buyers prioritizing communication efficiency. Jiangsu Enters offers mid-range pricing with diversified production lines, though its 91% on-time delivery rate warrants closer logistics scrutiny. Myoung Intelligent Technology supports flexible ordering (down to 1 piece) and maintains a 97% fulfillment rate, suitable for prototyping or niche applications. Guangzhou Fengear provides the widest functional range—from curtain rings to snap wrapping—but exhibits lower reorder metrics, suggesting potential gaps in after-sales follow-up.

FAQs

How to verify button maker machine supplier reliability?

Assess on-time delivery performance, reorder rates, and response times as proxies for operational stability. Request product videos or facility walkthroughs to confirm in-house manufacturing. Validate machine specifications against sample output for die accuracy and compression consistency.

What is the typical lead time for button making machines?

Standard models ship within 15–20 days after order confirmation. Customized configurations (e.g., multi-station rotary presses) may require 30–45 days depending on tooling adjustments and testing cycles.

Can suppliers accommodate low MOQs?

Yes, several suppliers offer single-unit orders, particularly for manual or desktop models. However, unit costs decrease significantly at 5+ sets, and shipping efficiency improves with container consolidation.

Do manufacturers provide technical support after purchase?

Response time and reorder rate data suggest varying levels of post-sale engagement. Suppliers with response times ≤6h are more likely to offer timely troubleshooting. Clarify warranty terms and spare parts availability before finalizing contracts.

How to initiate customization for specialized button formats?

Submit detailed requirements including diameter, shape (round, square, rectangle), material thickness, and desired output speed. Reputable suppliers will provide tooling quotes and prototype timelines within 48–72 hours.