Best Button Maker

1/29

1/29

1/15

1/15

1/10

1/10

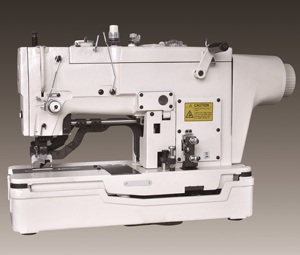

About best button maker

Where to Find Button Maker Suppliers?

China remains the global epicenter for button maker manufacturing, with key production clusters in Jiangsu, Zhejiang, and Guangdong provinces. These regions host vertically integrated supply chains that streamline component sourcing—from metal stamping dies to plastic molds—enabling rapid prototyping and scalable production. Jiangsu and Guangdong are particularly notable for their concentration of machinery OEMs specializing in manual, semi-automatic, and fully automatic button making systems.

The industrial ecosystems in these hubs support high-efficiency manufacturing through localized access to CNC machining, tooling workshops, and electronics integration facilities. This proximity reduces lead times by up to 30% compared to offshore alternatives and supports flexible order configurations, including mixed-model runs. Buyers benefit from average production cycles of 15–30 days for standard machines, with customization options such as die size adjustments (ranging from 25mm to 70mm) and rotary press configurations available across multiple suppliers.

How to Choose Button Maker Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Machine Type

Define requirements based on intended use: manual lever presses suit small-scale craft operations, while rotary or electric models serve commercial badge production. Confirm compatibility with standard button diameters (e.g., 50mm, 63.5mm) and material thicknesses. Verify machine durability through construction materials—steel-reinforced frames ensure longevity under repeated compression cycles.

Production Capacity Verification

Assess infrastructure indicators:

- Minimum factory area exceeding 2,000m² for stable output

- In-house tooling and mold-making capabilities

- Dedicated assembly lines for button press units

Cross-reference online revenue data and reorder rates as proxies for market acceptance and post-sale reliability.

Quality Assurance & Transaction Security

Prioritize suppliers demonstrating consistent quality control via documented on-time delivery rates (target ≥97%) and response times ≤6 hours. While formal certifications (ISO 9001, CE) are not universally listed, evaluate compliance readiness through product testing documentation and material traceability. Utilize secure payment mechanisms and request functional prototypes before scaling orders.

What Are the Best Button Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Jiangsu Enters Industrial Co., Ltd. | Jiangsu, CN | Button Making Machines, Display Racks, Sealing Machines | US $130,000+ | 91% | ≤4h | <15% | $399–550 | 1 set |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | Button Making Machines, Heat Press Machines | US $120,000+ | 100% | ≤3h | 17% | $60–338 | 1 set |

| HAO HANN ENTERPRISE CO., LTD. | Taiwan, CN | Automatic Button Machines, Garment Rivets, Stoppers | US $9,000+ | 100% | ≤6h | 33% | $2,300–3,700 | 1 set |

| Myoung Intelligent Technology (Shenzhen) Co., Ltd. | Guangdong, CN | Manual Button Makers, Inkjet Printers, DTF Equipment | US $20,000+ | 97% | ≤7h | 24% | $69–330 | 1 piece |

| Ganzhou Fuxing Intelligent Equipment Co., Ltd. | Jiangxi, CN | Industrial Sewing & Buttonhole Machines | Not disclosed | 100% | ≤3h | No data | $690–3,500 | 1–5 sets |

Performance Analysis

Yancheng Stik Pro and Ganzhou Fuxing lead in on-time performance (100% delivery rate) and responsiveness (≤3h), making them strong candidates for time-sensitive procurement. HA O HANN distinguishes itself with the highest reorder rate (33%), indicating customer retention likely driven by build quality in its higher-end automatic machines priced above $2,300. Jiangsu Enters offers premium-priced manual fridge magnet presses targeting niche markets, while Myoung Intelligent provides entry-level pricing ($69–$99 per unit) with low MOQs ideal for startups and small businesses. Ganzhou Fuxing’s offerings include industrial-grade electronic buttonhole sewing machines, catering to garment manufacturers rather than standalone badge producers.

FAQs

How to verify button maker supplier reliability?

Validate performance metrics through verifiable transaction histories, focusing on on-time delivery rates and reorder frequency. Request video tours of assembly lines to confirm production capacity. Evaluate build quality by ordering functional samples and testing crimp consistency across 50+ cycles.

What is the typical sampling timeline for button making machines?

Standard sample processing takes 7–14 days. Custom modifications, such as non-standard die sizes or dual-station setups, may extend lead times to 21 days. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate customization requests?

Yes, most suppliers offer die customization for round and square formats (e.g., 50x50mm, 70x25mm). Some provide voltage adaptations (110V/220V), ergonomic handles, or upgraded steel components upon request. Confirm feasibility during initial technical alignment.

Do manufacturers offer free samples?

Free samples are uncommon for complete machines due to unit cost. However, suppliers may waive fees for repeat buyers or offset sample charges against bulk orders (typically 5+ units). Component samples (e.g., finished buttons) are more frequently provided at minimal cost.

What are standard packaging and shipping terms?

Machines are typically export-packed in reinforced wooden crates with corner protectors and moisture barriers. FOB terms are standard; CIF can be arranged upon request. Full container loads (FCL) are recommended for multi-unit orders to optimize freight costs.