Amazing Button Maker

About amazing button maker

Where to Find Amazing Button Maker Suppliers?

China remains the central hub for button making machine production, with key manufacturing clusters in Zhejiang, Jiangsu, and Tianjin offering specialized capabilities. Wenzhou in Zhejiang Province is renowned for precision die-cutting and mold fabrication, enabling high-volume output of manual and semi-automatic button makers. Yancheng in Jiangsu has emerged as a center for integrated assembly lines, supporting mid-to-high-end machinery with rotating press mechanisms. Tianjin-based suppliers leverage proximity to Beijing’s R&D infrastructure, focusing on customizable, user-friendly designs for global craft and promotional markets.

These regional ecosystems support vertically integrated supply chains—from aluminum stamping and plastic injection molding to final packaging—reducing component lead times by 20–30%. Buyers benefit from localized access to raw materials like tinplate, ABS plastic, and ferrite magnets, which lowers material costs by 15% compared to offshore alternatives. Average production cycles range from 15–30 days for standard orders, with many suppliers offering modular designs that allow rapid reconfiguration for different button diameters (25mm to 75mm).

How to Choose Amazing Button Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Production and Customization Capability

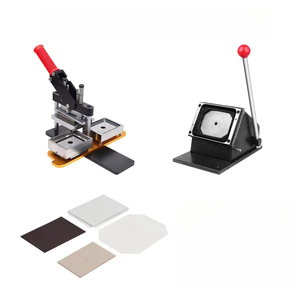

Assess whether suppliers can accommodate customization in size, shape (round, star, square), color, and branding elements such as logo embossing or custom packaging. Suppliers like Talent (Tianjin) Electronics Co., Ltd. and Yiwu Dongcheng Digital Technology Co., Ltd. explicitly list graphic, label, and magnet integration options. Prioritize manufacturers with in-house tooling capacity to avoid third-party mold dependencies.

Quality Assurance Metrics

While formal certifications (e.g., ISO 9001, CE) are not universally declared in available data, performance indicators offer proxy validation:

- On-time delivery rates ≥97% indicate reliable logistics execution

- Response times ≤3 hours reflect strong customer service infrastructure

- Reorder rates above 20% suggest customer satisfaction and product consistency

Cross-reference these metrics with order volume history; suppliers reporting over US $100,000 in online revenue typically maintain standardized QC processes and dedicated export teams.

Minimum Order Quantity and Pricing Flexibility

MOQs vary significantly—from 1 piece/set for entry-level manual machines to full container loads for automated systems. Manual models start at $16 per unit (Wenzhou Baiwang Precision Machinery), while pneumatic and fully automatic variants exceed $2,000 (Dongguan Mulong Robot Technology). Suppliers with multispecialty portfolios often provide bundling options (e.g., heat presses + button kits), enhancing cost efficiency for diversified procurement.

Transaction Security and Sampling

Utilize secure payment frameworks where possible, particularly for first-time engagements. Request physical samples before bulk ordering to verify build quality, ease of operation, and compatibility with intended materials. Most suppliers accommodate sample requests at incremental pricing, with lead times averaging 7–14 days.

What Are the Best Amazing Button Maker Suppliers?

| Company Name | Location | Verified Supplier Type | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Talent (Tianjin) Electronics Co., Ltd. | Tianjin, CN | Custom Manufacturer | Button Making Machines, Packaging, Cutters | US $330,000+ | 97% | ≤10h | <15% | $68 – $411 |

| Wenzhou Baiwang Precision Machinery Co., Ltd. | Zhejiang, CN | Multispecialty Supplier | Manual & Mold-Based Button Makers | US $50,000+ | 100% | ≤2h | 26% | $16 – $100 |

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Jiangsu, CN | - | Manual Rotating Press, Badge Makers | US $120,000+ | 100% | ≤3h | 18% | $60 – $400 |

| Dongguan Mulong Robot Technology Co., Ltd. | Guangdong, CN | - | Fully Automatic Snap Button Machines | - | 100% | ≤6h | - | $1,999 – $2,950 |

| Yiwu Dongcheng Digital Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | DIY Kits, Rotation Machines, 75mm Makers | US $110,000+ | 94% | ≤3h | 16% | $39 – $259 |

Performance Analysis

Wenzhou Baiwang stands out for responsiveness (≤2h) and repeat business (26% reorder rate), indicating strong post-sale reliability despite lower revenue volume. Yancheng Stik Pro and Dongguan Mulong represent contrasting segments: the former excels in affordable manual systems for small-scale users, while the latter specializes in industrial automation with CNC-integrated snap button production. Talent (Tianjin) leads in customization breadth but shows a relatively higher response time, suggesting potential bottlenecks during peak demand. For buyers prioritizing scalability and compliance, direct manufacturers with documented customization workflows and transparent pricing structures offer the lowest risk profile.

FAQs

How to verify button maker supplier reliability?

Evaluate on-time delivery records, response times, and reorder rates as proxies for operational stability. Request evidence of in-house production, such as factory videos or process documentation. For regulated markets, confirm compliance with material safety standards (e.g., RoHS for electronic components).

What is the typical lead time for button making machines?

Standard orders take 15–25 days for production, plus 7–14 days for international shipping via air or sea freight. Customized models may extend lead times by 10–15 days depending on design complexity and tooling requirements.

Can suppliers accommodate OEM/ODM requests?

Yes, multiple suppliers—including Talent (Tianjin) and Yiwu Dongcheng—list OEM services for color, logo, packaging, and labeling. Minimum volumes vary; some accept as low as 1 set for basic modifications, while structural redesigns may require 50+ units.

Are samples available before bulk ordering?

Most suppliers offer paid samples to validate product functionality and quality. Sample costs typically range from 1.5x to 2x the unit price, with partial refunds upon conversion to full orders.

What materials are compatible with these machines?

Commonly supported materials include tinplate, aluminum, ABS plastic, and paper inserts. Magnetic backings and double-sided adhesive options are available through select suppliers. Confirm diameter compatibility (e.g., 25mm, 58mm, 75mm) and required pressure settings based on substrate thickness.