The Best Button Maker

About the best button maker

Where to Find the Best Button Maker Suppliers?

China remains the global epicenter for button maker manufacturing, with key production clusters in Jiangsu, Guangdong, and Yancheng provinces. These regions host vertically integrated supply chains that combine metal stamping, mold fabrication, and assembly under one ecosystem, enabling rapid prototyping and scalable production. Jiangsu’s industrial corridor specializes in high-precision manual and semi-automatic button making machines, leveraging proximity to steel suppliers to reduce material costs by 15–20%. Meanwhile, Shenzhen and Guangzhou facilities focus on intelligent, multi-functional badge press systems integrated with digital control panels.

The concentration of component suppliers—such as die-casting units, spring mechanism producers, and plunger assembly workshops—within 50km radii allows for just-in-time manufacturing and shorter lead times. Buyers typically experience 15–30 days for sample fulfillment and 30–45 days for bulk orders, depending on customization complexity. This regional specialization supports both low-volume craft applications and industrial-scale garment accessory production, offering cost efficiencies of 25–40% compared to Western manufacturers.

How to Choose the Best Button Maker Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Machine Types

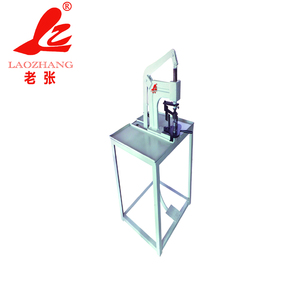

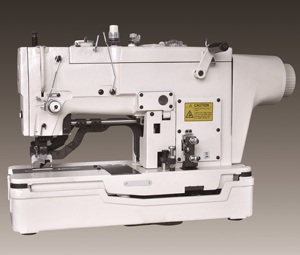

Assess whether the supplier offers models aligned with your production needs: manual lever presses for small batches, rotary dies for medium output, or fully automatic lines for high-volume operations. Key parameters include punch force (measured in kN), compatibility with standard sizes (25mm, 37mm, 50mm, 63mm), and adaptability to round, square, or custom-shaped badges. Suppliers with diverse product portfolios—such as those supporting fridge magnets, snap buttons, and curtain rings—demonstrate broader engineering capabilities.

Production Capacity Verification

Evaluate infrastructure indicators:

- Facility size exceeding 2,000m² indicates scalability

- In-house tooling and CNC machining capacity ensures faster iteration

- Dedicated R&D teams signal innovation potential

Cross-reference online revenue metrics and listing volume (e.g., >100 machine listings) with on-time delivery rates above 95% to validate consistency.

Quality Assurance & Transaction Security

While formal ISO 9001 certification is not universally declared, prioritize suppliers demonstrating quality control through verifiable performance data. Look for on-time delivery ≥97%, reorder rates >20%, and response times under 4 hours as proxies for reliability. Use secure payment frameworks and request pre-shipment inspection rights. Conduct functional testing of samples against durability benchmarks—particularly resistance to cap detachment after 100+ compression cycles.

What Are the Best Button Maker Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|

| Yancheng Stik Pro Machinery Equipment Co., Ltd. | Button Making Machines (944) | US $120,000+ | 100% | 17% | ≤3h | $39–256 | 1 set |

| Jiangsu Enters Industrial Co., Ltd. | Button Making Machines (225) | US $120,000+ | 91% | <15% | ≤4h | $399–550 | 1 set |

| HAO HANN ENTERPRISE CO., LTD. | Button Making Machines (109) | US $9,000+ | 100% | 33% | ≤7h | $1,300–3,700 | 1 set |

| Myoung Intelligent Technology (Shenzhen) Co., Ltd. | Button Making Machines (29) | US $20,000+ | 97% | 24% | ≤7h | $69–330 | 1 piece |

| Guangzhou Fengear Technology Co., Ltd. | Button Making Machines (11) | US $8,000+ | 100% | <15% | ≤3h | $25.99–990 | 1–10 sets |

Performance Analysis

Yancheng Stik Pro leads in market presence with nearly 1,000 listings and strong responsiveness, positioning it as a top-tier source for entry-level to mid-range manual machines. Jiangsu Enters targets premium segments with higher-priced models ($399–550), though its 91% on-time delivery rate introduces marginal risk for time-sensitive contracts. HAO HANN stands out for high-end automation, offering fully automatic systems priced above $2,500 with a 33% reorder rate—indicating strong customer retention despite slower response times. Myoung Intelligent provides competitive pricing for niche shapes (heart, square) and accepts single-piece orders, ideal for designers and startups. Guangzhou Fengear, while diversified in apparel machinery, offers budget-friendly options down to $25.99 but has limited specialization in dedicated badge equipment.

FAQs

How to verify the best button maker supplier reliability?

Analyze on-time delivery records, reorder rates, and response speed as behavioral proxies for service quality. Request factory videos or third-party audit reports if available. Test machine durability via sample compression cycles and inspect weld integrity on frame joints.

What is the typical sampling timeline for button makers?

Standard manual machines are typically dispatched within 7–15 days after order confirmation. Automated systems may require 20–30 days due to calibration and programming. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate custom button shapes and sizes?

Yes, most established manufacturers support custom dies for non-standard geometries (e.g., hearts, rectangles). Minimum order quantities for custom tooling range from 500 to 1,000 units per design. Confirm die modification lead time (typically 10–14 days) before finalizing agreements.

Do suppliers offer free samples?

Free samples are uncommon for machinery. Most suppliers charge full or partial fees, which may be credited toward future bulk orders. Sample costs typically cover 30–50% of unit production expenses.

What are standard MOQ and payment terms?

MOQs vary: many accept 1-set trials for standard models, while customized configurations may require 10+ sets. Payment terms often include T/T (30% deposit, 70% before shipment), with some supporting trade assurance programs for added security.