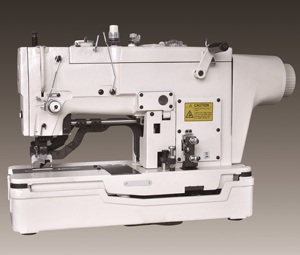

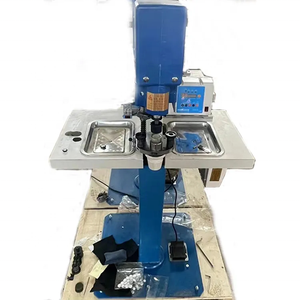

Best Fabric Button Maker

1/13

1/13

CN

CN

1/20

1/20

1/15

1/15

About best fabric button maker

Where to Find Fabric Button Maker Suppliers?

China remains the global hub for fabric button maker manufacturing, with key industrial clusters in Zhejiang, Guangdong, and Shandong provinces. These regions host vertically integrated supply chains that combine precision machining, textile processing, and automated assembly under one ecosystem. Taizhou and Shenzhen serve as innovation centers for semi-automatic and computer-controlled models, while Shandong specializes in hydraulic and high-tonnage press systems designed for heavy-duty textile applications.

The concentration of component suppliers—ranging from die-casting units to servo motor providers—within 50km radii enables rapid prototyping and scalable production. This proximity reduces material procurement time by 25–40% compared to decentralized markets. Buyers benefit from established logistics networks offering direct air and sea freight access, with standard lead times averaging 15–30 days for containerized shipments. Localized manufacturing also supports cost efficiency, delivering 20–35% lower unit prices than equivalent machinery produced in Southeast Asia or Europe.

How to Choose Fabric Button Maker Suppliers?

Selecting reliable suppliers requires a structured evaluation of technical, operational, and transactional performance indicators.

Technical Capability Verification

Assess machine specifications against production requirements: manual presses suit small-batch operations (under 500 units/day), while fully automatic feed systems are optimal for volumes exceeding 2,000 units/day. Confirm compatibility with target materials—including cotton, wool, polyester blends, and laminated fabrics—and verify punch force ratings (measured in kN) match button diameter and thickness specifications.

Production Infrastructure Audit

Prioritize suppliers demonstrating measurable operational capacity:

- Minimum factory area of 3,000m² indicating dedicated production lines

- In-house tooling and mold-making capabilities to support customization

- Integration of CNC machining and hydraulic system assembly

Cross-reference facility scale with on-time delivery rates above 90% and response times under 6 hours to assess reliability and service responsiveness.

Quality & Transaction Assurance

While formal certifications (ISO 9001, CE) are not universally listed, prioritize suppliers with documented quality control processes, including pre-shipment testing protocols. Utilize secure payment mechanisms such as escrow services, especially when engaging newer suppliers. Request product samples to evaluate build quality, consistency, and ease of integration into existing workflows before full-scale ordering.

What Are the Best Fabric Button Maker Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Taizhou Vma Sewing Machine Co., Ltd. | Zhejiang, CN | Sewing Machines, Apparel Machinery, Embroidery Equipment | US $10,000+ | 33% | ≤10h | 100% | No | 1–5 sets |

| Myoung Intelligent Technology (Shenzhen) Co., Ltd. | Guangdong, CN | Button Making Machines, Heat Presses, DTF Printers | US $20,000+ | 97% | ≤6h | 27% | No | 1 piece |

| Shandong Soar Machinery Co., Ltd. | Shandong, CN | Fabric Cutting & Button Cover Machines | US $440,000+ | 84% | ≤4h | <15% | Yes | 1 set |

| Longnan County Shengming Machinery Equipment Co., Ltd. | Jiangxi, CN | Sewing Machines, Injection Molding Equipment | US $30,000+ | 100% | ≤3h | 50% | No | 1–5 sets |

| Guangzhou Disen Electromechanical Equipment Co., Ltd | Guangdong, CN | Automatic Button Sewing, Upholstery Machines | US $380,000+ | 100% | ≤5h | 37% | Yes | 1 set |

Performance Analysis

Longnan County Shengming and Guangzhou Disen demonstrate the highest operational reliability with 100% on-time delivery and sub-5-hour average response times, making them ideal for time-sensitive procurement. Shandong Soar and Guangzhou Disen offer customization options for color, size, logo, and packaging—critical for OEM integration. Myoung Intelligent stands out for low MOQs (as low as 1 piece), catering to startups and R&D departments. Despite a lower reorder rate, Shandong Soar’s high online revenue suggests strong export volume and market penetration. For high-volume buyers, Taizhou VMA offers a broad product range but exhibits below-average delivery performance, warranting closer logistical oversight.

FAQs

What is the typical MOQ for fabric button makers?

MOQs vary significantly: manual models often have no minimum (1-piece orders accepted), while automated industrial machines typically require 1–5 sets. Bulk pricing applies at 5+ units for most mid-range models.

How long does production and shipping take?

Manufacturing lead time ranges from 7–20 days depending on automation level and customization. Standard shipping via sea freight adds 25–35 days for international delivery. Air freight reduces transit to 5–10 days at higher cost.

Can suppliers customize button makers for specific fabric types?

Yes, select suppliers offer adjustments in punch pressure, die shape, and feeding mechanism to accommodate delicate or thick textiles. Custom molds may incur additional tooling fees and extended setup time.

Do fabric button makers require certification for import?

While not always mandatory, CE marking enhances compliance with safety standards in EU and North American markets. Buyers should confirm electrical and mechanical safety documentation prior to shipment.

Are samples available before bulk purchase?

Most suppliers provide sample units for testing. Costs are typically borne by the buyer, though some offset fees upon order confirmation. Sample lead time averages 7–14 days.