Fabric Button Making

About fabric button making

Where to Find Fabric Button Making Suppliers?

China remains the central hub for fabric button manufacturing and related machinery, with key production clusters in Guangdong, Zhejiang, and Shandong provinces. These regions host vertically integrated supply chains that support both finished garment accessories and specialized equipment for automated button assembly. Guangzhou and Shenzhen serve as primary centers for small-batch fabric-covered buttons, offering rapid prototyping and low minimum order quantities (MOQs) ideal for fashion designers and boutique apparel brands. Meanwhile, Yiwu and Qingdao specialize in high-volume component production, leveraging economies of scale to deliver bulk orders at competitive unit prices.

The industrial ecosystem enables dual sourcing strategies: direct procurement of ready-made fabric buttons or investment in in-house production via automated button-making machines. Localized access to textile substrates, metal blanks, molds, and assembly tools reduces lead times by 20–35% compared to offshore alternatives. Buyers benefit from consolidated logistics networks capable of fulfilling container-load shipments within 15–25 days from order confirmation, supported by established export channels across Europe, North America, and Southeast Asia.

How to Choose Fabric Button Making Suppliers?

Effective supplier selection requires evaluation across three core dimensions:

Product & Process Alignment

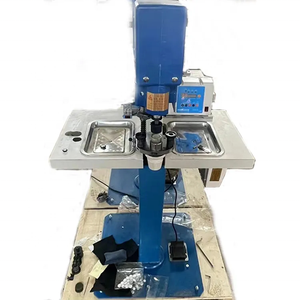

Determine whether the need is for finished fabric-covered buttons or production equipment. Suppliers like Guangzhou Jie’an Accessories Co., Ltd. focus on handcrafted woven and cloth-covered buttons (priced from $0.45/piece, MOQ 10 pieces), while companies such as Taizhou Woxing Machinery Co., Ltd. offer industrial-grade button-making machines (ranging from $240–$2,650/set). Confirm compatibility between machine specifications (e.g., mold size, material thickness tolerance) and intended fabric types (cotton, wool, PU leather).

Production Capacity Verification

Assess infrastructure readiness through measurable indicators:

- Minimum factory area exceeding 3,000m² for machinery producers

- In-house tooling and mold fabrication capabilities

- Dedicated quality control stations with pre-shipment inspection protocols

Cross-reference online transaction volumes and reorder rates (e.g., suppliers with >20% repeat buyer ratios indicate consistent performance).

Transaction Reliability Metrics

Prioritize partners demonstrating verified operational consistency. On-time delivery rates above 97%, response times under 5 hours, and participation in secure payment systems enhance procurement safety. For higher-value equipment purchases, require technical documentation including CE marking, electrical safety compliance, and mechanical performance testing records.

What Are the Best Fabric Button Making Suppliers?

| Company Name | Main Products | Price Range | Min. Order | On-Time Delivery | Avg. Response | Reorder Rate | Revenue Tier |

|---|---|---|---|---|---|---|---|

| Guangzhou Jie'an Accessories Co., Ltd. | Fabric-covered buttons, trimmings, patches | $0.45–$0.60/unit | 10–100 pcs | 97% | ≤5h | 28% | US $10,000+ |

| Yiwu Dingpin Trading Ltd. | Fabric cover buttons, molds, aluminum buttons | $0.01–$10.58/unit | 2–2000 pcs | 100% | ≤2h | <15% | US $5,000+ |

| Taizhou Woxing Machinery Co., Ltd. | Industrial button-making machines | $201–$2,650/set | 1 set | 100% | ≤8h | 20% | US $130,000+ |

| Qingdao Liaode Machinery Co., Ltd. | Cap button machines, automatic fabric button makers | $60–$4,500/set | 1 set/carton | 100% | ≤10h | 20% | US $10,000+ |

| Shenzhen Hde Garment Accessories Co., Ltd. | Metal fabric-covered buttons, DIY kits, semi-auto machines | $0.03–$95/unit | 10–100 sets | 97% | ≤4h | 23% | US $40,000+ |

Performance Analysis

Yiwu Dingpin Trading Ltd. and Taizhou Woxing Machinery demonstrate perfect on-time delivery records, indicating strong logistical execution despite differing business models—one focusing on consumable components, the other on capital equipment. Guangzhou Jie’an and Shenzhen Hde achieve higher reorder rates (28% and 23%), suggesting superior product consistency and customer service alignment for accessory buyers. For machine procurement, Taizhou Woxing and Qingdao Liaode offer scalable solutions with price tiers matching manual, semi-automatic, and fully automatic production needs. Suppliers with response times under 5 hours (Guangzhou, Shenzhen, Yiwu) provide faster iteration cycles crucial for time-sensitive design development.

FAQs

What are typical MOQs for fabric button making products?

Finished buttons can have MOQs as low as 10 pieces (e.g., embroidered flower buttons), while bulk fabric-covered metal buttons require 1,000–2,000 units. Machinery is typically sold per set with no volume obligation. Custom designs may require MOQs of 500–1,000 units depending on complexity.

How long does production and shipping take?

Standard button orders ship within 7–15 days after confirmation. Machine deliveries range from 15–30 days due to technical configuration. Add 5–10 days for international air freight or 25–40 days for sea shipment. Expedited processing is available from select suppliers for urgent runs.

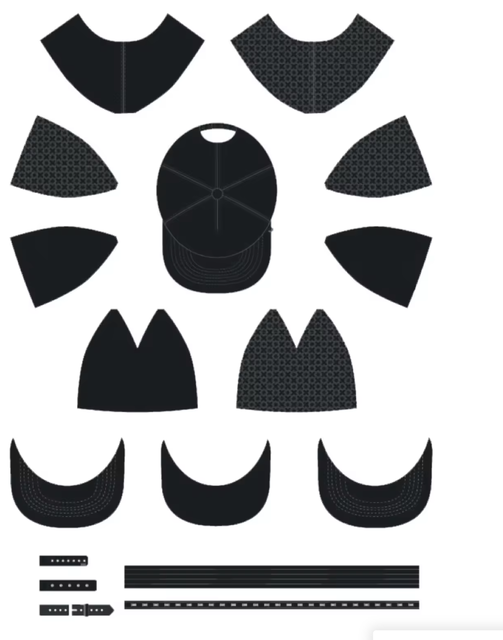

Can suppliers customize fabric buttons?

Yes, most suppliers accept custom fabrics, diameters (15mm–30L), and backing materials (aluminum, brass, plastic). Provide swatches or digital patterns for sample creation. Tooling modifications for unique shapes may incur one-time mold fees ranging from $50–$200.

Are fabric button making machines CE certified?

Industrial models from manufacturers like Taizhou Woxing and Qingdao Liaode typically include CE certification upon request. Verify inclusion of compliance documentation during quotation stages, especially for EU market entry. Electrical safety and mechanical guarding standards must be explicitly confirmed.

Do suppliers offer samples before bulk orders?

Free or low-cost samples are commonly offered—especially for button variants priced under $0.10/unit. Sample costs are often credited toward first full orders. Expect 3–7 days for sample preparation and dispatch, depending on customization level.