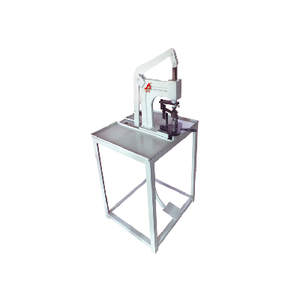

Cloth Button Maker

About cloth button maker

Where to Find Cloth Button Maker Suppliers?

China remains the global epicenter for cloth button maker manufacturing, with key supplier clusters concentrated in Zhejiang, Henan, and Shandong provinces. Hangzhou in Zhejiang Province hosts specialized machinery firms leveraging advanced servo-driven automation and precision die-cutting technologies. Zhengzhou, Henan, serves as a hub for mid-to-high-volume producers integrating mechanical stamping and fabric-wrapping systems, supported by regional metal and textile supply chains that reduce component costs by 15–25%. Shandong’s Qingdao region focuses on niche, high-precision equipment tailored for garment accessory production, particularly for fashion and upholstery applications.

These industrial zones offer vertically integrated ecosystems where raw material sourcing, machining, assembly, and quality control occur within compact geographic radii—typically under 50 km. This integration enables lead times averaging 20–35 days for standard machine orders and supports flexible customization in tooling, pressing force (ranging from 1–10 tons), and fabric compatibility (cotton, wool, polyester, and blended textiles). Buyers benefit from scalable production capacity, with established suppliers capable of fulfilling single-unit trials up to container-load exports of 50+ units monthly.

How to Choose Cloth Button Maker Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Compliance

Verify machine compatibility with intended materials and button sizes (commonly 10–38mm diameter). Confirm compliance with international safety standards such as CE or IEC 60204-1 for electrical systems. While formal ISO 9001 certification is not universally declared in available data, prioritize suppliers demonstrating documented quality control processes, including pre-shipment testing for press consistency and cycle durability.

Production Capacity & Infrastructure

Assess operational scale through key indicators:

- Minimum factory area exceeding 3,000m² for stable output

- In-house R&D or engineering teams capable of customizing molds and feeding mechanisms

- Integration of CNC machining and servo-control systems for automated models

Cross-reference listed product ranges with response time and on-time delivery metrics—suppliers maintaining ≤3-hour response times and 98–100% fulfillment rates demonstrate operational reliability.

Transaction Security & Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk. Request sample units to evaluate build quality, noise levels, and pressing accuracy before bulk ordering. Conduct virtual audits via video tours to validate facility conditions and workflow organization. Analyze reorder rates as a proxy for customer satisfaction—suppliers with rates above 30% indicate consistent performance and service quality.

What Are the Best Cloth Button Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization |

|---|---|---|---|---|---|---|---|---|

| Hangzhou Qike Technology Co., Ltd. | Zhejiang, CN | Sewing Machines (563) | US $420,000+ | 100% | ≤2h | 18% | $60–930 | No explicit mention |

| Zhengzhou Hanchuang Machinery Co., Ltd. | Henan, CN | Leather Production Machinery (364) | US $50,000+ | 100% | ≤3h | 30% | $150–1,999 | No explicit mention |

| Qingdao Laozhang Cap Device Co., Ltd. | Shandong, CN | Button Making Machines (39) | US $9,000+ | Not specified | ≤3h | <15% | $160–6,000 | Limited listings |

| Quanzhou Jordon Sewing Equipment Co., Ltd. | Fujian, CN | Used Sewing Machines (245) | US $40,000+ | 100% | ≤3h | 33% | $60–2,700 | No explicit mention |

| Henan Penghui Machinery And Equipment Co., Ltd. | Henan, CN | No primary listing data | US $350,000+ | 98% | ≤3h | <15% | $4,320–7,560 | Color, material, size, logo, packaging |

Performance Analysis

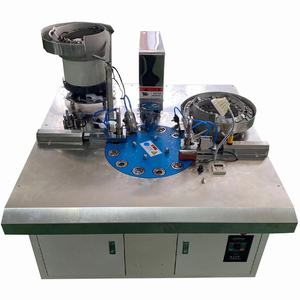

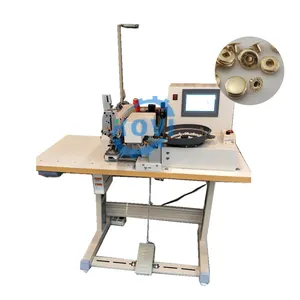

Hangzhou Qike Technology leads in volume diversity and responsiveness, offering entry-level electric snap machines from $60 alongside semi-automatic circular presses, ideal for small workshops. Zhengzhou Hanchuang and Quanzhou Jordon stand out for after-sales reliability, both achieving 100% on-time delivery and reorder rates of 30% and 33% respectively—indicative of strong buyer trust. Henan Penghui targets premium industrial clients with fully automatic systems priced over $7,500, backed by comprehensive customization options including branded packaging and OEM labeling. Despite higher price points, their investment in client-specific design support suits buyers requiring integration into automated apparel lines. Notably, suppliers with broader machinery portfolios (e.g., leather and quilting equipment) demonstrate cross-sector engineering expertise applicable to complex button fabrication workflows.

FAQs

How to verify cloth button maker supplier reliability?

Cross-check declared delivery performance against transaction history and buyer feedback. Request evidence of machine testing protocols, such as pressure calibration logs or cycle endurance reports. For high-value purchases, commission third-party inspection services to audit factory operations prior to order placement.

What is the typical MOQ and lead time?

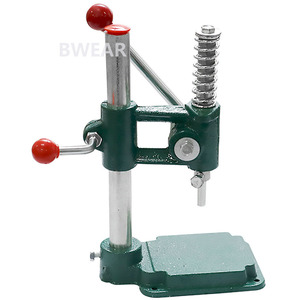

Minimum Order Quantities range from 1 set for standard models to 100–200 sets for manual or handheld variants. Lead times average 15–30 days post-payment confirmation, with additional time required for customized configurations involving unique mold designs or voltage adaptations (110V/220V).

Can suppliers customize cloth button making machines?

Yes, select manufacturers like Henan Penghui offer full customization in pressing force, mold size, material feed mechanisms, and branding elements. Custom development typically requires technical drawings or physical samples, with prototype validation completed within 3–5 weeks.

Do suppliers provide machine operation training or after-sales support?

While not explicitly stated in all profiles, leading suppliers commonly include basic setup guides, instructional videos, and remote troubleshooting via email or messaging platforms. Extended support, including on-site technician deployment, may be negotiated for large-scale installations.

Are used or refurbished cloth button makers available?

Yes, certain suppliers such as Quanzhou Jordon list Japan-made used equipment at reduced prices (e.g., $510–660 per unit), catering to budget-conscious buyers. However, due diligence on wear-and-tear, spare parts availability, and compatibility with local power systems is essential when purchasing pre-owned machinery.