Clothes Button Maker

About clothes button maker

Where to Find Clothes Button Maker Suppliers?

China remains the central hub for clothes button maker manufacturing, with key production clusters in Guangdong, Zhejiang, and Wenzhou provinces. These regions host vertically integrated supply chains that specialize in garment machinery and accessories, enabling efficient production of manual, semi-automatic, and fully automatic button making machines. Shenzhen and Hangzhou serve as innovation centers, combining precision engineering with scalable manufacturing for both domestic and export markets.

The industrial ecosystem supports rapid prototyping and high-volume output, with many suppliers operating end-to-end facilities encompassing die-casting, CNC machining, and final assembly. This integration reduces component lead times and lowers unit costs by 15–25% compared to non-specialized manufacturers. Buyers benefit from consolidated sourcing—machines, dies, and consumables like metal blanks or fabric covers—are often available from single suppliers, streamlining procurement and logistics.

How to Choose Clothes Button Maker Suppliers?

Selecting reliable partners requires a structured evaluation of technical capability, operational performance, and transactional reliability.

Technical & Production Capability

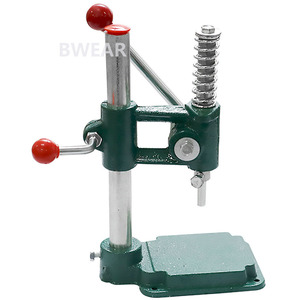

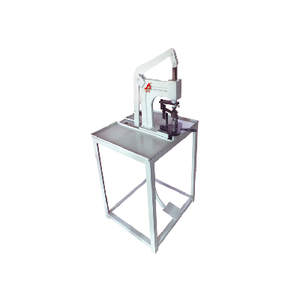

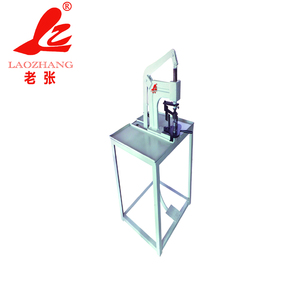

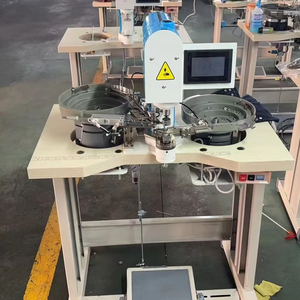

Assess whether suppliers possess in-house engineering teams capable of supporting customization, such as adjustable mold sizes (ranging from 10mm to 38mm) or compatibility with diverse materials including metal, plastic, and fabric-covered substrates. Confirm access to CNC machining, hydraulic pressing systems, and pneumatic actuation technologies. For automated models, verify integration of programmable logic controllers (PLCs) and servo-driven mechanisms that ensure consistent attachment force (typically 300–600N).

Quality Assurance & Compliance

While formal ISO 9001 certification is not universally listed, prioritize suppliers demonstrating documented quality control processes. Look for evidence of functional testing per batch, material traceability, and CE marking where applicable—particularly for electric or pneumatic models destined for EU or North American markets. RoHS compliance should be confirmed for metal components to meet environmental regulations.

Order Flexibility & Commercial Terms

Minimum Order Quantities (MOQs) vary significantly—from 1 set for basic manual machines to 5–10 sets for industrial-grade electric models. Unit prices range from $14.50 for handheld tools to over $4,500 for fully automatic cap-button lines. Lead times average 15–30 days post-payment, depending on customization level. Most suppliers accommodate OEM labeling and color customization upon request, particularly those advertising “customization options” in their profiles.

Supplier Performance Indicators

On-time delivery rates across top-tier suppliers consistently exceed 97%, with response times averaging under 7 hours. Reorder rates between 16% and 22% indicate moderate customer retention, suggesting room for differentiation through service and product consistency. Prioritize suppliers with dedicated support channels and transparent communication, especially when coordinating technical specifications or shipping logistics.

What Are the Best Clothes Button Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Key Offerings |

|---|---|---|---|---|---|---|---|

| Shenzhen Star Print Electronic Equipment Co., Ltd. | Guangdong, CN | Hole Punches (141), Binding Machines (86) | US $80,000+ | 100% | ≤1h | 17% | Manual and semi-automatic button makers; competitive pricing from $21.85/set |

| Wenzhou Banwei Garment Accessory Co., Ltd. | Zhejiang, CN | Pliers (24), Rhinestones (14) | US $20,000+ | 100% | ≤7h | 20% | Budget-friendly manual presses ($14.50–$25); DIY kits at $0.30/unit |

| Hangzhou Anysew Garment Equipment Co., Ltd. | Zhejiang, CN | Customization-focused | US $70,000+ | 100% | ≤7h | 22% | Electric snap machines ($145–200); pneumatic punchers; strong customization support |

| Shenzhen Hde Garment Accessories Co., Ltd. | Guangdong, CN | Buttons (512), Buckles (32) | US $40,000+ | 97% | ≤4h | 22% | Wide model range: manual ($19) to semi-auto fabric cover machines ($820+) |

| Qingdao Liaode Machinery Co., Ltd. | Shandong, CN | Cap Making Machines (45), Parts (79) | US $10,000+ | 100% | ≤11h | 16% | High-end automatic systems ($4,500–$4,600); specialized in baseball cap button automation |

Performance Analysis

Shenzhen- and Hangzhou-based suppliers lead in responsiveness and customization depth, with two companies achieving sub-7-hour response times and full on-time delivery records. Hangzhou Anysew and Shenzhen Hde demonstrate strong technical breadth, offering everything from entry-level manual tools to industrial electric systems. Wenzhou Banwei stands out for low-cost manual units ideal for small workshops or craft applications. Qingdao Liaode occupies a niche in automated apparel production, particularly for headwear manufacturers requiring high-speed, consistent button attachment. Despite lower online revenue, its $4,500+ automatic machines reflect advanced engineering and process integration.

FAQs

How to verify clothes button maker supplier reliability?

Evaluate on-time delivery history, response time metrics, and product listing consistency. Request sample units to assess build quality, press alignment, and ease of die更换 (die change). Verify material compatibility—especially for fabric-covered or resin buttons—and confirm availability of spare parts and technical documentation.

What is the typical sampling timeline?

Standard samples are typically dispatched within 7–14 days. Custom configurations involving unique mold sizes or voltage adaptations may require 20–30 days. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate custom branding or design?

Yes, most suppliers listed offer OEM services including logo printing, packaging customization, and color variation. Minimum thresholds usually apply—typically 100+ units—depending on machine type and complexity.

Do button making machines require special power or infrastructure?

Manual models operate without power. Electric and pneumatic variants require standard 220V/110V AC input or compressed air systems (6–8 bar pressure). Confirm local voltage compatibility and include transformers if necessary.

How to negotiate better terms with suppliers?

Leverage order volume for price reductions—suppliers often offer tiered pricing above 10 sets. Combine machine purchases with consumables (blanks, fabric rolls) to increase bargaining power. Use Trade Assurance or similar escrow mechanisms to secure payment until acceptance testing is completed.