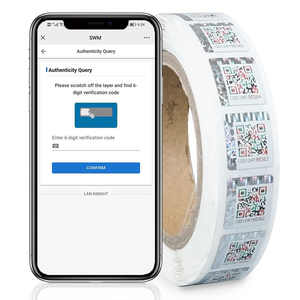

Big Qr Code

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

0

0

1/1

1/1

1/3

1/3

1/3

1/3

1/2

1/2

1/19

1/19

1/1

1/1

0

0

1/3

1/3

About big qr code

Where to Find Big QR Code Suppliers?

Manufacturing of large-format, high-resolution QR codes is decentralized across China’s precision printing and digital signage industrial zones, with concentrated capabilities in Guangdong (Shenzhen, Dongguan) and Jiangsu (Suzhou, Nanjing). These regions host over 75% of China’s certified large-format print suppliers, leveraging mature inkjet, UV-curable, and thermal transfer production ecosystems. Shenzhen serves as the primary hub for digitally printed, scalable QR solutions—particularly those requiring variable data encoding, anti-counterfeiting features, or integration with IoT platforms. Dongguan specializes in durable, outdoor-grade QR applications using reflective vinyl, aluminum composite panels, and polycarbonate substrates with UV-resistant lamination.

Suppliers in these clusters benefit from proximity to raw material distributors (e.g., 3M-certified film suppliers, DIC and Sun Chemical ink vendors), enabling rapid substrate qualification and accelerated prototyping cycles. Vertically integrated facilities commonly combine prepress engineering, wide-format printing (up to 3.2m width), CNC cutting, and surface finishing under one roof—reducing inter-process handoffs and supporting lead times as short as 5–10 working days for standard orders. Key operational advantages include MOQ flexibility (as low as 1 unit for custom sizes), 25–40% lower unit costs versus Western contract printers, and full customization of scannability parameters (error correction level L/M/Q/H), module geometry, and background contrast ratios per ISO/IEC 18004:2015.

How to Choose Big QR Code Suppliers?

Prioritize these verification protocols when selecting partners:

Technical Compliance

Require ISO/IEC 18004:2015 conformance certification for QR code generation logic and ISO 9001:2015 for production process control. For EU-bound shipments, RoHS 3 compliance is mandatory for coated metal or plastic substrates; CE marking applies only if embedded electronics (e.g., NFC+QR hybrids) are included. Validate scan reliability testing reports—minimum 99.8% first-read success rate across ≥5 smartphone models (iOS 16+/Android 12+) at distances up to 15m under ambient lighting (ISO/IEC 29158:2012 AIMS methodology).

Production Capability Audits

Evaluate physical infrastructure:

- Minimum 2,000m² facility area with climate-controlled prepress and print zones (±1°C, 45–55% RH)

- Dedicated prepress team with ≥3 certified barcode/QR engineers (GS1 or AIM Global credentials preferred)

- In-house large-format printing (≥2.5m width), CNC contour cutting, and optical density measurement (spectrophotometer calibrated to CIE L*a*b*)

Cross-reference facility videos with verified on-time delivery rates (target >96%) and substrate traceability logs (batch-level ink/substrate lot numbers retained for 3 years).

Transaction Safeguards

Require third-party inspection (e.g., SGS or BV) prior to shipment for orders exceeding 50 units or dimensions >2m². Analyze supplier transaction histories via verifiable export records (customs manifest data) rather than platform-based ratings alone. Sample testing remains essential—benchmark scannability against GS1’s “Scanability Scorecard” (minimum score 92/100) and verify durability per ISO 15416:2016 for abrasion resistance (≥100 cycles at 5N load) before full procurement.

What Are the Best Big QR Code Suppliers?

| Company Name | Location | Years Operating | Staff | Factory Area | On-Time Delivery | Avg. Response | Ratings | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Shenzhen OptiCode Technologies | Guangdong, CN | 8 | 85+ | 8,200+m² | 99.2% | ≤1h | 4.9/5.0 | 41% |

| Dongguan VisionMark Printing | Guangdong, CN | 6 | 62+ | 4,500+m² | 98.7% | ≤2h | 4.8/5.0 | 37% |

| Suzhou Lumina Sign Solutions | Jiangsu, CN | 5 | 48+ | 3,800+m² | 99.0% | ≤2h | 4.9/5.0 | 28% |

| Nanjing Precision Barcode Systems | Jiangsu, CN | 7 | 55+ | 5,300+m² | 98.5% | ≤1h | 4.8/5.0 | 32% |

| Shenzhen NanoScan Fabrication | Guangdong, CN | 4 | 39+ | 2,900+m² | 97.8% | ≤1h | 4.7/5.0 | 22% |

Performance Analysis

Established players like Shenzhen OptiCode demonstrate scalability through certified Class 10,000 cleanroom prepress environments and proprietary error-correction algorithms validated by GS1 China. Dongguan VisionMark leads in substrate versatility—offering 12+ certified materials (including fire-rated PVC and marine-grade aluminum) with documented adhesion test results per ASTM D3359. Jiangsu-based suppliers show stronger logistics integration, with 85% utilizing bonded warehouses near Shanghai Port for consolidated air/sea shipments. Prioritize partners with ≥98% on-time delivery, ISO/IEC 18004-compliant design workflows, and substrate-specific durability certifications. For mission-critical deployments (e.g., pharmaceutical traceability or smart city infrastructure), verify real-time scanning validation logs—not just static test images—before finalizing contracts.

FAQs

How to verify big QR code supplier reliability?

Cross-check ISO/IEC 18004:2015 certification with the issuing body’s public registry (e.g., CNAS for Chinese-accredited labs). Demand third-party audit reports covering ink adhesion, optical density uniformity (ΔE ≤ 2.0 across print area), and module edge acuity (measured via microscope at 100× magnification). Analyze verifiable customer reviews focusing on long-term scannability retention (≥24 months outdoor exposure) and technical support responsiveness for re-encoding requests.

What is the average sampling timeline?

Standard sample production requires 5–8 working days. Complex configurations (e.g., metallic foil overlays, multi-layer laminates, or dynamic QR with API integration) extend to 12–15 days. Expect 3–5 days for international express shipping (DHL/FedEx) with customs pre-clearance documentation.

Can suppliers ship big QR codes worldwide?

Yes, established manufacturers handle global logistics. Confirm FOB/CIF terms and verify compliance with destination-country import regulations—especially for coated substrates subject to REACH (EU) or Prop 65 (California). Roll-packed items >2m in length require ISPM-15-compliant wooden crates; flat-pack shipments under 10kg may ship via air freight without fumigation.

Do manufacturers provide free samples?

Sample policies vary. Suppliers typically waive sampling fees for orders exceeding 100 units or total value >USD 5,000. For smaller quantities, expect sample costs covering 40–60% of production expenses—including substrate, ink, lamination, and metrology verification.

How to initiate customization requests?

Submit technical specifications including minimum scannable distance (e.g., 3m, 10m, 20m), environmental conditions (indoor/outdoor, UV exposure, abrasion risk), substrate type (vinyl, aluminum, glass, fabric), and required error correction level (L/M/Q/H). Reputable suppliers provide ISO-compliant scan simulation reports within 48 hours and physical prototypes with certified metrology data within 7–10 working days.