Bldc Stator Core Supplier

Top sponsor listing

Top sponsor listing

1/1

1/1

CN

CN

1/37

1/37

1/24

1/24

CN

CN

1/29

1/29

0

0

1/3

1/3

0

0

1/3

1/3

0

0

1/3

1/3

1/13

1/13

1/48

1/48

1/28

1/28

0

0

1/3

1/3

1/3

1/3

CN

CN

1/14

1/14

0

0

About bldc stator core supplier

Where to Find BLDC Stator Core Suppliers?

China remains the global hub for precision motor component manufacturing, with key production clusters in Zhejiang, Jiangsu, and Guangdong provinces. These regions host vertically integrated facilities specializing in laminated stator cores for brushless DC (BLDC) motors, leveraging localized access to high-grade electrical steel, advanced stamping technologies, and experienced engineering talent. Ningbo and Changzhou serve as core centers for magnetic material processing, while Shenzhen supports rapid prototyping and customization through precision tooling and automation.

The industrial ecosystem enables efficient scaling from low-volume OEM projects to high-volume production runs. Suppliers benefit from co-located material suppliers, heat treatment services, and coil winding partners within 50km radii, reducing logistics overhead and lead times. Buyers can expect typical production cycles of 20–35 days for custom orders, with cost advantages of 15–25% over equivalent Western or Southeast Asian manufacturers due to optimized supply chains and in-house process control.

How to Choose BLDC Stator Core Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Material Expertise

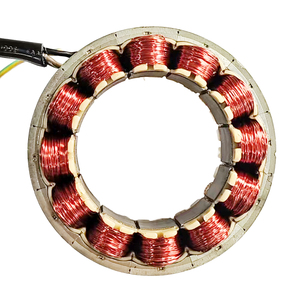

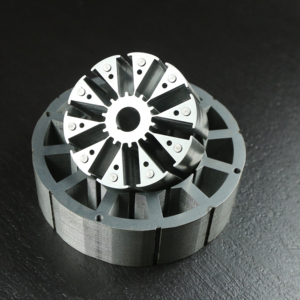

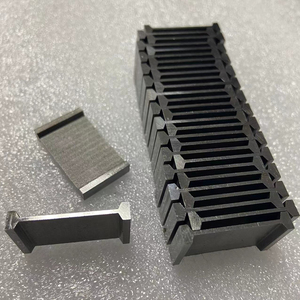

Verify use of standard electrical steel grades such as 50AW600, 35WW270, or equivalent silicon-iron alloys. Suppliers should demonstrate capability in progressive die stamping, TIG welding, or laser bonding for lamination stacking, with tight tolerance control (±0.02mm). Inspect available customization options including slot count (e.g., 12S, 24S), pole configurations (8P, 18P), insulation treatments, and stacking height adjustments.

Quality Assurance Protocols

Prioritize suppliers adhering to ISO 9001 standards for quality management. Request documentation on dimensional inspection reports, core loss testing, and surface coating integrity. Reorder rates below 15% across multiple suppliers indicate consistent product reliability, while response times under 4 hours suggest robust customer support infrastructure.

Production & Customization Capacity

Assess whether the manufacturer offers full design-to-production services, including CAD-based modeling, prototype development, and small-batch trials. Key indicators include:

- In-house tooling and mold-making capabilities

- Support for material, size, logo, packaging, and labeling customization

- Minimum Order Quantities (MOQs) ranging from 10 to 50 pieces, depending on complexity

- Monthly output capacity inferred from online transaction volume and order history

Transaction Reliability

Analyze performance metrics where available: On-time delivery rates at or above 97% are preferred. Cross-reference revenue benchmarks—suppliers with verified annual online revenues exceeding US $20,000 typically maintain stable operations. For higher-value contracts, initiate sample validation before bulk procurement and confirm post-sales technical support availability.

What Are the Best BLDC Stator Core Suppliers?

| Company Name | Main Products | Customization Options | On-Time Delivery | Reorder Rate | Avg. Response Time | Online Revenue | Verification Status |

|---|---|---|---|---|---|---|---|

| Ningbo BMAG New Materials Co., Ltd. | Magnetic Materials | Color, material, size, logo, packaging, label, graphic | 100% | <15% | ≤4h | US $2,000+ | Custom Manufacturer |

| Shenzhen Xintai Precision Products Co., Ltd | Other Motor Accessories, Fabrication Services | Not specified | 70% | 33% | ≤10h | US $20,000+ | Not specified |

| Changzhou Wujin Luoyang Chuangxinkai Motor Co.,ltd | Custom BLDC Rotor/Stator Assemblies | Color, material, size, logo, packaging, label, graphic | 100% | <15% | ≤4h | US $6,000+ | Custom Manufacturer |

| Ningbo Haofeng Magnet Technology Co., Ltd. | Silicon Steel, Permanent Magnet Components | Not specified | 100% | <15% | ≤2h | US $4,000+ | Custom Manufacturer |

| Shanghai Primopal Precision Motor Co., Ltd. | BLDC Servo Motor Stators, PM Motors | Material, size, torque, waterproofing, noise reduction, gearbox integration | 100% | <15% | ≤3h | US $450,000+ | Multispecialty Supplier |

Performance Analysis

Suppliers like Shanghai Primopal and Ningbo BMAG demonstrate strong reliability with 100% on-time delivery and reorder rates below 15%, indicating high customer satisfaction. Primopal stands out with extensive customization depth—including water-resistant and pressure-resistant designs—and the highest reported online revenue, suggesting significant export activity and market trust. Ningbo Haofeng excels in responsiveness (≤2h), making it suitable for time-sensitive development cycles.

In contrast, Shenzhen Xintai shows a lower on-time delivery rate (70%) and higher reorder rate (33%), which may reflect capacity constraints or inconsistent quality control. While its MOQs start as low as 50 packs, buyers should conduct additional due diligence, including sample testing and facility verification, before engaging in large-scale procurement.

FAQs

What materials are commonly used in BLDC stator cores?

Most suppliers use cold-rolled non-oriented silicon steel (e.g., 50AW600, 35WW300) for optimal magnetic permeability and low core loss. Alternative materials include amorphous alloys or ferrites for specialized high-frequency applications.

What is the typical MOQ and pricing range?

MOQs vary from 10 to 50 pieces depending on supplier and complexity. Unit prices range from $1.00 for standardized components to over $40 for fully customized, wound, or insulated assemblies.

How long does it take to receive samples?

Sample lead times average 10–20 days, including design review, tooling setup (if new), and production. Shipping adds 5–10 days via express courier. Some suppliers offer expedited 7-day sampling for repeat clients.

Can stator cores be customized with branding or special coatings?

Yes, multiple suppliers support custom labels, laser logos, color coding, and protective epoxy or insulating coatings. Graphic and packaging personalization is available for OEM partnerships.

Do suppliers provide technical drawings and testing data?

Reputable manufacturers supply DWG, STEP, or PDF drawings upon request and may provide B-H curve data, insulation resistance tests, and dimensional inspection reports for validation.