Bldc Stator Distributor

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About bldc stator distributor

Where to Find BLDC Stator Distributors?

China remains the central hub for BLDC stator manufacturing, with key supplier clusters in Zhejiang and Jiangsu provinces offering vertically integrated production ecosystems. Ningbo and Changzhou serve as core industrial zones, hosting specialized manufacturers equipped with automated coil winding, lamination stacking, and insulation treatment lines. These regions benefit from proximity to silicon steel producers and precision tooling workshops, enabling material cost reductions of 15–25% compared to non-specialized markets.

Suppliers in these clusters typically operate semi-automated to fully automated production lines, supporting monthly outputs ranging from 50,000 to over 500,000 units depending on complexity. The integration of CNC stamping, laser welding, and vacuum impregnation systems ensures dimensional accuracy and thermal stability in stators used in HVAC, electric vehicles, and industrial automation. Buyers gain access to scalable capacity, rapid prototyping (within 7–14 days), and low minimum order quantities (MOQs) starting at 2–1000 pieces across different configurations.

How to Choose BLDC Stator Distributors?

Evaluate suppliers using the following technical and operational benchmarks:

Production & Engineering Capability

Confirm availability of in-house tooling and winding equipment. Leading suppliers maintain dedicated R&D teams for custom electromagnetic design, supporting pole counts from 4 to 16 and voltage ranges from 12V to 400V. Prioritize vendors with coil winding machines and mold fabrication capabilities, as these indicate control over critical process parameters such as turn consistency and slot fill ratio.

Quality Assurance Systems

While formal ISO 9001 certification is not universally declared in available data, performance indicators suggest variability in quality discipline. Target suppliers with documented on-time delivery rates above 90% and response times under 12 hours. Reorder rates exceeding 25%—as seen with select high-service providers—indicate customer satisfaction and product reliability.

- On-time delivery ≥90% for supply chain predictability

- Response time ≤2–11 hours for timely engineering coordination

- Reorder rate >20% as a proxy for post-sale performance

Customization & Transaction Security

Assess flexibility in material selection (e.g., 50WW470, 35WW300 silicon steel), wire gauge, insulation class (B/F), and lead configuration. Top-tier distributors support full customization of outer diameter, stack height, and winding patterns via CAD/CAM inputs. Use secure transaction models where payment milestones are tied to production stages and sample validation. Request physical or digital samples before scaling orders to verify electrical resistance, inductance, and mechanical fit.

What Are the Best BLDC Stator Distributors?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | MOQ Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Ningbo Imcore Machinery & Electronics Co., Ltd. | Ningbo, CN | Other Motor Accessories (161), Coil Winding Machines | $10,000+ | 71% | ≤11h | 20% | 2–1000 pcs | $1–$15 |

| Ningbo Haofeng Magnet Technology Co., Ltd. | Ningbo, CN | Custom BLDC Motors, Permanent Magnet Assemblies | $4,000+ | 100% | ≤2h | <15% | 5–20 pcs | $10–$120 |

| Zhongshan Pengfei Electrical Appliance Co., Ltd. | Zhongshan, CN | Stator Laminations, Universal Motor Components | $300,000+ | 86% | ≤2h | 25% | 1000–2000 pcs | $0.24–$0.29 |

| Changzhou Modar Intelligent Technology Co., Ltd. | Changzhou, CN | Custom Stators, Silicon Steel Cores, BLDC Motors | $4,000+ | 100% | ≤10h | <15% | 2 pcs | $0.23–$70 |

Performance Analysis

Zhongshan Pengfei leads in volume efficiency with sub-dollar unit pricing and high reorder activity, making it suitable for mass production runs. Ningbo Haofeng and Changzhou Modar achieve perfect on-time delivery records, with Haofeng excelling in rapid communication—a critical factor for iterative design projects. Modar stands out for ultra-low MOQs (as low as 2 pieces), ideal for prototyping and niche applications. Imcore offers broad product diversity but lags in delivery performance, suggesting potential bottlenecks in fulfillment. Buyers requiring tight tolerances and export-grade consistency should prioritize suppliers with documented quality controls and responsive technical teams.

FAQs

What materials are commonly used in BLDC stators?

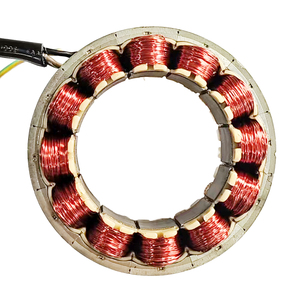

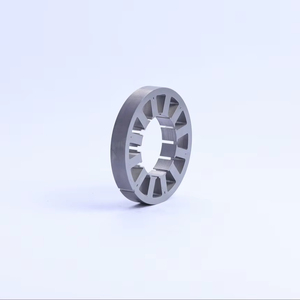

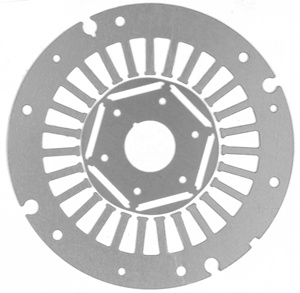

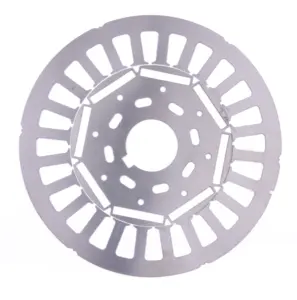

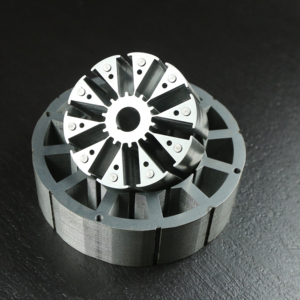

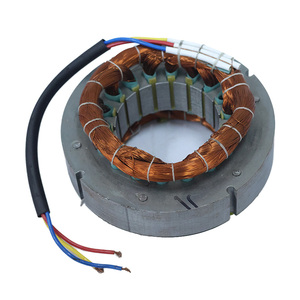

Silicon steel grades such as 50WW470 and 35WW300 are standard for laminations due to their high permeability and low core loss. Insulation materials include varnish, slot liners (Nomex, Mylar), and encapsulation resins. Copper magnet wire with polyurethane or enamel coating is typical for windings.

What is the typical lead time for BLDC stator orders?

Standard orders take 15–30 days from confirmation. Custom designs with new tooling may require 35–50 days, including prototype validation. Rush production can reduce timelines by 30% with expedited fees.

Can suppliers provide stators without final assembly?

Yes, most distributors offer bare stators, wound cores, or laminated stacks based on buyer requirements. Some also supply flat lamination sets for local winding operations.

Do BLDC stator suppliers support OEM/ODM services?

Multiple suppliers listed offer full customization—including core geometry, winding schematics, labeling, and packaging—under OEM/ODM agreements. Technical drawings and 3D models are typically required to initiate development.

How are stators tested before shipment?

Basic electrical tests include continuity, resistance, inductance, and hipot checks. Advanced suppliers perform back-EMF testing, surge testing, and thermal cycling. Request test reports for batch traceability and compliance verification.