Brick And Mortar To Ecommerce Examples

CN

CN

CN

CN

CN

CN

About brick and mortar to ecommerce examples

Where to Find Brick and Mortar to Ecommerce Suppliers?

China remains a central hub for industrial building material production, with key manufacturing clusters in Henan, Guangxi, and Shandong provinces driving innovation in brick and mortar solutions tailored for digital commerce. These regions host vertically integrated facilities capable of producing both raw construction materials—such as dry-mix mortars and precast blocks—and advanced machinery for brick fabrication, enabling seamless transitions from physical production to online distribution models.

The supply ecosystem supports dual procurement streams: bulk material suppliers offering ready-to-ship mortar and block products, and heavy machinery manufacturers providing automated systems for on-site or decentralized production. This integration allows businesses to scale operations efficiently, whether launching e-commerce storefronts for construction supplies or establishing localized manufacturing units to serve regional markets. Buyers benefit from consolidated sourcing options, reduced component lead times, and access to customization at competitive price points.

How to Choose Brick and Mortar to Ecommerce Suppliers?

Selecting reliable partners requires structured evaluation across technical, operational, and transactional dimensions:

Production & Customization Capacity

Assess suppliers’ ability to support branding and specification adjustments. Leading vendors offer customization in color, material composition, size, mold design, packaging labeling, and machine configuration (e.g., hydraulic press type, power source). For machinery providers, confirm availability of full production lines including conveyors, stackers, and mixers. Material suppliers should demonstrate formulation flexibility for cement-based, AAC, or eco-block variants.

Performance Metrics Verification

Prioritize suppliers with documented performance indicators:

- On-time delivery rate exceeding 90% (verified through platform data)

- Average response time under 3 hours

- Reorder rates above 30%, indicating customer satisfaction

- Minimum factory area supporting batch processing (e.g., ≥5,000m² for machinery producers)

Cross-reference these metrics with product listing volume and revenue estimates where available.

Transaction Security & Quality Assurance

Require evidence of quality management systems, even if formal certifications are not listed. Evaluate order fulfillment reliability by reviewing minimum order quantities (MOQs), pricing consistency, and sample availability. Use secure payment methods tied to delivery milestones, particularly for high-value machinery transactions. Pre-shipment inspections are recommended for orders exceeding $10,000.

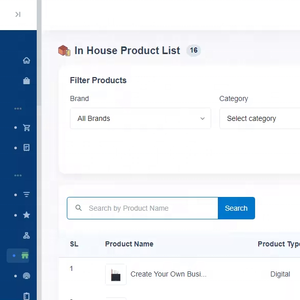

What Are the Best Brick and Mortar to Ecommerce Suppliers?

| Company Name | Main Products | Price Range (USD) | MOQ | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Linyi Xiangrong Machinery Co., Ltd. | Dry plaster, bonded mortar, premix concrete | $150–180 | 1 ton | 40% | ≤2h | 50% | US $170,000+ | Color, material, size, logo, packaging, graphic |

| Gongyi Wanlong Machinery Manufacturing Co., Ltd. | Brick making machines, earth block equipment | $600–$5,400 | 1 set | 97% | ≤3h | 26% | US $410,000+ | Conveyor, diesel option, solar, mold, machine size, brick type, packaging |

| Guangxi Hongfa Heavy Machinery Co., Ltd. | Automatic curbstone, AAC block, pallet clamp machines | $24,500–$800,000 | 1 set | 75% | ≤5h | 33% | US $10,000+ | Block size, thickness, patterns, colors, capacity, hollow/solid types, panel dimensions |

| NEW ERA BLOCK TILE JOINT STOCK COMPANY | Industrial-style EBLOCK, water-resistant mortar | $1.80–$6.50 | 800 bags / 2,500 m³ | - | ≤4h | - | - | Limited public data; focus on standard product lines |

| Gongyi Xiaoyi Hongying Machinery Factory | Interlocking brick machines, tunnel kilns, block machinery | $850–$3,500 | 1 set | 96% | ≤3h | 36% | US $200,000+ | Mold size, color, brick type, conveyor, vibrators, electric/diesel motor, packaging |

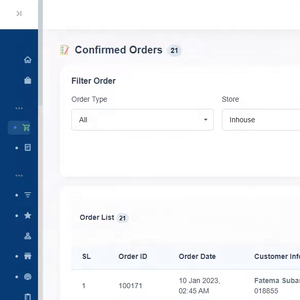

Performance Analysis

Gongyi Wanlong and Gongyi Xiaoyi Hongying stand out for high on-time delivery (97% and 96%) and strong customization breadth, making them suitable for buyers requiring tailored machinery configurations. Linyi Xiangrong offers the highest reorder rate (50%), suggesting strong post-sale satisfaction among repeat clients despite moderate delivery performance. NEW ERA BLOCK focuses on standardized building blocks and plastic flooring, ideal for bulk e-commerce resellers prioritizing consistent SKU availability over bespoke designs. Guangxi Hongfa targets large-scale infrastructure projects with high-ticket automation systems, though longer response times may affect agility. Price-sensitive buyers can leverage sub-$1,000 manual brick machines, while those scaling production should consider fully automated lines priced above $25,000.

FAQs

What is the typical MOQ for brick and mortar products?

For dry mortar and pre-mixed compounds, MOQs start at 1 ton or 800 bags. Machinery units typically require 1 set as minimum order. Larger production lines may have higher thresholds based on system complexity.

How long does it take to fulfill an order?

Standard mortar shipments can be dispatched within 15–20 days. Machinery production lead times range from 25–45 days depending on customization level. Add 10–14 days for international shipping via sea freight.

Can suppliers provide OEM/ODM services?

Yes, most machinery and material suppliers listed offer OEM branding through customizable packaging labels, logos, and graphical elements. Some support full ODM development for specialized block shapes or machine configurations upon technical submission.

Are samples available before bulk ordering?

Sample policies vary. Material suppliers often provide small test batches (e.g., 50kg) at nominal cost. Machinery suppliers may offer digital renderings or video demonstrations; physical prototypes are rare due to size and cost but can be arranged under special agreements.

What payment terms are common?

Typical arrangements include 30% advance payment with balance against shipment documents. High-value machinery orders may require letters of credit (L/C). Escrow-based transactions are advised for first-time engagements to mitigate risk.