Building Cladding Materials

Top sponsor listing

Top sponsor listing

CN

CN

About building cladding materials

Where to Find Building Cladding Materials Suppliers?

China remains a dominant force in the global building cladding materials market, with key manufacturing clusters concentrated in Jiangsu, Chongqing, and Shandong provinces. These regions host vertically integrated production ecosystems that combine raw material processing, advanced coating technologies, and precision fabrication—enabling competitive pricing and rapid scalability. Changzhou and Shanghai-based suppliers leverage proximity to port infrastructure for efficient export logistics, while Chongqing’s industrial base benefits from lower inland labor and energy costs, reducing production expenses by 10–15% compared to coastal counterparts.

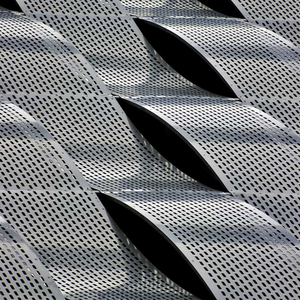

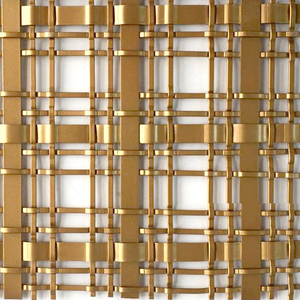

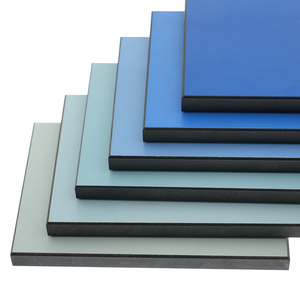

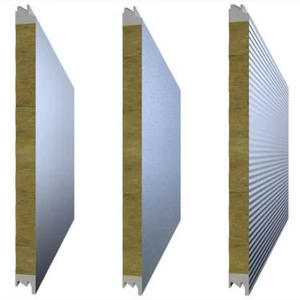

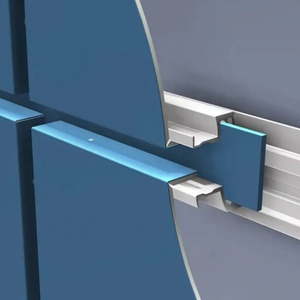

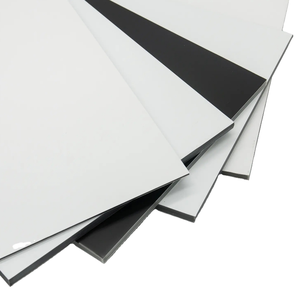

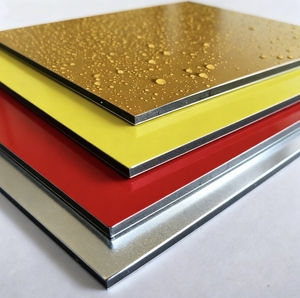

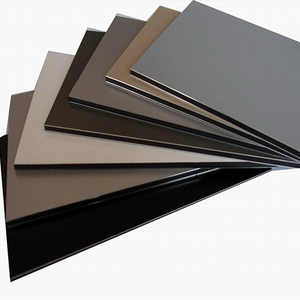

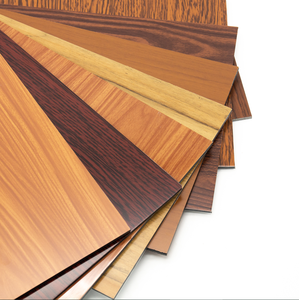

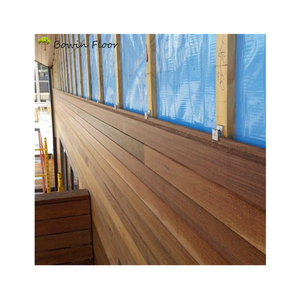

The sector is characterized by diversified material specialization: aluminum composite panels (ACPs), fiber cement boards, wood-plastic composites (WPC), high-pressure laminates (HPL), and engineered stone dominate output. Facilities typically integrate coil coating lines, CNC cutting, laser engraving, and digital printing capabilities, supporting both standard and custom architectural finishes. Buyers gain access to flexible MOQs (as low as 30 square meters for premium metal cladding) and lead times averaging 20–35 days for containerized orders. The presence of in-house R&D teams at leading firms enables rapid prototyping and compliance with international fire safety standards such as A1/A2 non-combustibility ratings.

How to Choose Building Cladding Materials Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional criteria:

Material & Fire Performance Compliance

Verify product conformity with regional building codes. For commercial façades, demand test reports certifying non-combustibility (EN 13501-1 A1/A2) or Class A fire ratings. Suppliers offering WPC or polymer-based cladding must provide ASTM E84 smoke density and flame spread data. Request independent lab certifications for UV resistance, colorfastness (≥8 years warranty), and weathering performance.

Production Capability Assessment

Evaluate core manufacturing competencies through documented evidence:

- Facility size exceeding 5,000m² indicating scalable operations

- In-house capabilities including roll forming, embossing, anodizing, powder coating, and interlocking profile extrusion

- Customization support for gauge, width, length, edge profiles, and surface textures

Cross-reference online revenue metrics and on-time delivery rates (>97%) to assess fulfillment reliability.

Quality Control & Transaction Security

Prioritize suppliers with structured QC protocols, including batch testing, pre-shipment inspections, and packaging designed for long-haul transport. Analyze reorder rates as an indicator of customer satisfaction—suppliers below 15% suggest consistent quality and service. Utilize secure payment mechanisms and request physical or digital samples before full-scale ordering to validate finish, tolerance, and assembly compatibility.

What Are the Best Building Cladding Materials Suppliers?

| Company Name | Main Products | Customization Options | Min. Order Quantity | On-Time Delivery | Avg. Response Time | Reorder Rate | Online Revenue |

|---|---|---|---|---|---|---|---|

| Changzhou Panels New Material Co., Ltd. | Decorative HPL, Laboratory & Hospital Cabinets, Outdoor Tables | Color, material, size, logo, packaging, graphic | Not specified | 100% | ≤1h | <15% | US $40,000+ |

| Chongqing Guanjie Qizhong Building Materials Co., Ltd. | Fireproof Facade Cladding, Non-Asbestos Curtain Wall Panels | Color, material, size, painting, 3D model, logo, pre-coated finishes | 300 m² | 100% | ≤3h | <15% | US $40,000+ |

| Matrixtion Building Materials Co., Limited | Aluminum Cladding, Interlocking Metal Siding, Timber-Look Systems | Color, thickness, battens, trims, fixings, angle, rendering, laser cutting | 30–50 m² | 100% | ≤2h | <15% | US $400,000+ |

| Shanghai Ecoarch Building Materials Co., Ltd. | Fiber Cement Board, Aluminum Foam Composite, Translucent Panels | Color, material, size, design, logo, packaging | 50–200 m² | 97% | ≤13h | 19% | US $100,000+ |

| Shandong Huishengjia Building Materials Co., Ltd. | Artificial Stone, WPC Cladding, Carbon Crystal Boards, Decking | Color, texture, profile, logo, graphic | 10–60 m² / 50 meters | 100% | ≤1h | <15% | US $30,000+ |

Performance Analysis

Matrixtion Building Materials stands out with the highest reported online revenue (US $400,000+), indicating strong market penetration and export activity, supported by extensive customization for architectural detailing. Changzhou Panels and Shandong Huishengjia demonstrate superior responsiveness (≤1h average), critical for time-sensitive design coordination. Chongqing Guanjie specializes in fire-rated solutions ideal for high-rise applications, with MOQs aligned to large-scale projects. Shanghai Ecoarch offers cost-effective fiber cement and foam aluminum options but exhibits a higher reorder rate (19%), suggesting potential gaps in consistency or post-sale support. Suppliers with sub-15% reorder rates generally reflect stable quality and buyer retention.

FAQs

How to verify building cladding material compliance?

Request certified test reports for fire reaction (EN 13501-1), mechanical strength (tensile, impact resistance), and environmental durability (salt spray, thermal cycling). Validate third-party assessments from accredited labs such as SGS or Intertek, particularly for façade systems in regulated markets.

What is the typical lead time for cladding material orders?

Standard orders require 20–35 days from confirmation, depending on complexity and finishing processes. Custom colors or profiles may extend timelines by 10–15 days. Expedited production is available from select suppliers with modular manufacturing lines.

Can suppliers accommodate small-batch or sample orders?

Yes, most suppliers accept trial orders starting from 30–50 square meters or linear meters for decking/WPC. Sample turnaround averages 7–14 days, with shipping via air freight adding 5–10 days globally. Some suppliers offer free samples contingent on subsequent bulk procurement.

Do manufacturers provide design and installation support?

Leading suppliers offer BIM models, CAD drawings, 3D renderings, and system-specific fixings. Technical teams assist in specifying expansion joints, drainage integration, and wind load compliance, especially for curtain wall and rainscreen assemblies.

What are common customization options for cladding systems?

Available modifications include surface texture (brushed, matte, wood grain), color matching (RAL/Pantone), panel dimensions, edge types (shiplap, tongue-and-groove), integrated insulation backing, and branding elements (laser-cut logos, custom packaging).