Built In Nugget Ice Maker

Top sponsor listing

Top sponsor listing

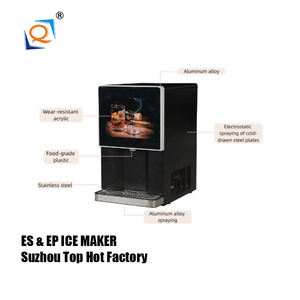

About built in nugget ice maker

Where to Find Built-in Nugget Ice Maker Suppliers?

China remains the dominant manufacturing hub for built-in nugget ice makers, with key production clusters concentrated in Shanghai, Guangzhou, and Zhejiang. These regions host vertically integrated supply chains encompassing compressor fabrication, evaporator assembly, and refrigeration system integration. Shanghai-based suppliers leverage proximity to international ports and advanced cold chain logistics, enabling efficient export operations to North America and Europe—key markets for commercial and residential ice-making equipment.

The industrial ecosystem supports rapid prototyping and scalable production, with many facilities operating automated assembly lines capable of producing 500–2,000 units per month. Suppliers in these clusters benefit from localized access to stainless steel, food-grade plastics, and condenser components, reducing material lead times by 15–25% compared to offshore alternatives. Buyers gain flexibility in MOQs ranging from 1 unit for sample validation to full container loads (FCL) for bulk procurement, supported by established export compliance frameworks.

How to Choose Built-in Nugget Ice Maker Suppliers?

Effective supplier selection requires a structured evaluation across technical, operational, and transactional criteria:

Technical and Quality Compliance

Verify adherence to international standards such as CE, RoHS, and ISO 9001, particularly for electrical safety and refrigerant handling. For commercial-grade units, confirm UL or ETL certification readiness if targeting North American markets. Demand documentation on compressor lifespan testing, energy efficiency ratings (kWh/100 lbs), and condensation management systems.

Production and Customization Capacity

Assess core capabilities through the following indicators:

- Minimum factory area exceeding 3,000m² for sustained output

- In-house design teams supporting OEM/ODM services including panel layout, logo imprinting, and color customization

- Capacity for stainless steel fabrication and sealed refrigeration loop assembly

Cross-reference product listings with reorder rates above 20% and on-time delivery performance ≥95% to validate reliability.

Procurement and Risk Mitigation

Utilize secure payment mechanisms such as escrow or letter of credit for initial orders. Prioritize suppliers offering sample units with lead times under 15 days. Conduct virtual audits via facility videos to verify automation levels and quality control checkpoints. Insist on third-party inspection reports (e.g., SGS or BV) before shipment, especially for high-volume contracts.

What Are the Best Built-in Nugget Ice Maker Suppliers?

| Company Name | Location | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options |

|---|---|---|---|---|---|---|---|

| Shanghai Chuangli Refrigeration Equipment Co., Ltd. | Shanghai, CN | Ice Machines (569) | US $15,000,000+ | 100% | ≤5h | 40% | Color, material, size, logo, packaging, graphic |

| Guangzhou Universal Venture Holding Co., Ltd | Guangzhou, CN | Ice Machines (85) | US $260,000+ | 100% | ≤7h | 33% | Not specified |

| Shanghai Bingsu Refrigeration Technology Co., LTD. | Shanghai, CN | Ice Machines (452) | US $20,000+ | 100% | ≤1h | 20% | Not specified |

| Cixi Jirui Electric Appliance Co., Ltd. | Zhejiang, CN | Ice Makers (135) | US $3,000+ | 75% | ≤6h | <15% | Not specified |

| Wellcooling Intelligent Technology (JM) Co., Ltd. | Guangdong, CN | Ice cream machine (368) | US $140,000+ | 100% | ≤9h | 16% | Not specified |

Performance Analysis

Shanghai Chuangli stands out with the highest online revenue and a 40% reorder rate, indicating strong market acceptance and repeat buyer confidence. The company offers extensive customization options across materials, branding, and packaging, making it suitable for private-label partnerships. Guangzhou Universal Venture demonstrates reliable fulfillment (100% on-time delivery) and solid reorder volume despite lower customization visibility.

Shanghai Bingsu excels in responsiveness (≤1h average reply time) and maintains perfect delivery performance, though its lower reorder rate suggests room for customer retention improvement. Cixi Jirui shows limited reliability with a 75% on-time delivery rate and sub-15% reorder frequency, signaling potential operational constraints. Wellcooling, while diversified in snack machinery, maintains consistent delivery but slower response cycles.

For high-volume buyers, prioritize suppliers with verified production infrastructure and customization support. For niche or specialty designs, engage partners offering engineering collaboration and prototype development within 10–14 days.

FAQs

How to verify built-in nugget ice maker supplier reliability?

Validate certifications through official registries and request test reports for noise levels (dB), daily production capacity (lbs/day), and power consumption. Analyze transaction history, focusing on dispute resolution outcomes and post-sale service responsiveness.

What is the typical sampling timeline?

Standard samples are produced within 7–14 days. Custom configurations involving modified dimensions or branding extend timelines to 20–25 days. Air freight adds 5–10 days for international delivery.

Can suppliers accommodate OEM/ODM requests?

Yes, leading suppliers support full OEM/ODM workflows including custom enclosures, control panels, and packaging. Minimum order quantities for branded units typically start at 50–100 pieces, depending on complexity.

What are common MOQ and pricing structures?

MOQ ranges from 1 piece for standard models to 2 cartons (≈20–50 units) for commercial variants. Unit prices vary from $35 for compact units to over $6,000 for high-capacity commercial dispensers, influenced by compressor type, insulation grade, and finish materials.

How to assess long-term supplier viability?

Evaluate financial stability through revenue benchmarks, workforce size, and export experience. Suppliers with multi-year operating histories, dedicated R&D teams, and diversified product portfolios demonstrate greater resilience for ongoing partnerships.