Bulk Computer Scrap

About bulk computer scrap

Where to Find Bulk Computer Scrap Suppliers?

The global supply of bulk computer scrap is concentrated among specialized recyclers and industrial processors, primarily operating in regions with established e-waste recycling ecosystems. These suppliers source end-of-life computing hardware from institutional decommissioning, data centers, and OEM take-back programs, processing materials through mechanical shredding, separation, and sorting technologies. Key operations are distributed across multiple geographies, with a notable presence in markets offering flexible import frameworks for secondary raw materials.

Suppliers leverage economies of scale by aggregating high-volume lots—typically 10 tons or more—for efficient export. Processing capabilities include automated dismantling lines and non-ferrous metal recovery systems, particularly targeting copper, aluminum, gold-bearing components, and ceramic-based CPU substrates. The availability of standardized material streams (e.g., motherboard scrap, RAM modules, CPUs) enables buyers to align procurement with specific refining or reprocessing objectives. Lead times for containerized shipments generally range from 25–40 days post-payment, depending on loading port and destination logistics infrastructure.

How to Choose Bulk Computer Scrap Suppliers?

Procurement decisions should be guided by systematic evaluation of supplier reliability, material consistency, and transactional safeguards:

Material Composition & Grading

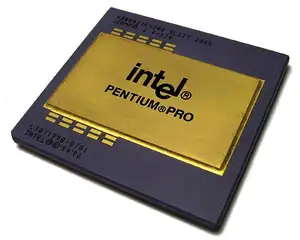

Verify detailed component breakdowns for each lot. High-value streams such as CPU ceramic scrap contain recoverable precious metals (gold, palladium), while mixed motherboard or RAM scrap offers balanced yields of base metals. Request sample analyses or XRF reports where available to confirm metal content and absence of hazardous contaminants (e.g., brominated flame retardants).

Minimum Order Quantity (MOQ) and Pricing Structure

MOQs vary significantly across suppliers:

- Standard bulk suppliers: 1,000 kg minimum at $3–5/kg

- Specialty processors (e.g., CPU-focused): 50–100 kg at $10–$25/kg

- High-grade or pre-sorted lots: 10-ton minimums priced up to $210/ton ($0.21/kg)

Higher per-kilogram prices often reflect refined categorization (e.g., ceramic CPU scrap) or lower contamination levels. Buyers should assess cost-efficiency based on net recoverable value rather than unit price alone.

Supplier Responsiveness and Transaction Security

Prioritize partners with response times under 8 hours and documented on-time delivery performance. Use secure payment mechanisms such as third-party escrow services to mitigate risk until shipment verification. Confirm packaging standards (e.g., palletized big bags, container loading protocols) to prevent moisture exposure or physical degradation during transit.

What Are the Leading Bulk Computer Scrap Suppliers?

| Company Name | Main Products | Price Range | Min. Order | Response Time | Specialization |

|---|---|---|---|---|---|

| SARL SOC DANIEL H PIAT | Recycled Plastic, Beef, Hand Tools | $3–5 | 1,000 kg | ≤16h | Mixed computer scrap, bulk |

| REKHAMOKA HOLDINGS (PTY) LTD | Copper Scrap, Animal Feed, Spices | $25–50 | 100 kg | ≤7h | CPU processor, ceramic scrap |

| JACK MANUFACTURING LLC | Container Houses, Recycling Products | $10 | 50 kg | ≤8h | Precious metal-bearing CPU scrap |

| ELU TRADING GMBH | Steel Scrap, Copper Scrap, Seafood | $70–210 | 10 tons | ≤8h | High-purity CPU and motherboard scrap |

| AGRI-HR LTD | Used Tractors, Agricultural Equipment | $4–225 | 175 kg / 15 tons | ≤3h | Ceramic CPU scrap, bulk compressor units |

Performance Analysis

SARL SOC DANIEL H PIAT and AGRI-HR LTD offer entry-level pricing ideal for high-volume recyclers focused on bulk throughput. REKHAMOKA HOLDINGS and JACK MANUFACTURING LLC target niche demand for higher-grade CPU scrap, reflected in elevated pricing and smaller MOQs suitable for precious metal refiners. ELU TRADING GMBH stands out for large-scale contracts, supporting full-container orders with consistent grading and competitive lead times. AGRI-HR LTD demonstrates superior responsiveness (≤3h), making it a strategic choice for time-sensitive sourcing cycles. Suppliers with diversified product portfolios often maintain flexible inventory but may require stricter material verification to ensure grade accuracy.

FAQs

How to verify bulk computer scrap quality?

Request digital samples or video inspections of loaded containers. For repeat orders, conduct independent lab testing on received batches to validate metal content and compliance with RoHS or WEEE directives where applicable. Cross-check declared material types against known specifications (e.g., Intel PENTIUM ceramic package composition).

What is the typical lead time for bulk scrap shipments?

Production and loading timelines average 20–30 days after order confirmation. Add 15–30 days for ocean freight depending on origin and destination ports. Air freight is rarely economical except for small, high-value test batches.

Can suppliers provide customized sorting or preprocessing?

Limited customization is available. Some suppliers offer pre-crushed material, magnetic separation of ferrous elements, or manual segregation of CPUs and RAM. Full material stream customization requires long-term contracts and minimum volume commitments (typically 50+ tons/month).

Are there environmental or import regulations to consider?

Yes. Importing e-waste-derived scrap is restricted under the Basel Convention in many countries. Buyers must confirm classification status (e.g., "processed scrap" vs. "waste") and ensure documentation meets local customs requirements. Pre-shredded or smelted forms face fewer restrictions than whole boards or unprocessed assemblies.

Is sampling available before bulk purchase?

Most suppliers allow sample purchases, typically ranging from 1–5 kg at commercial rates. Samples help evaluate material mix, connector density, and presence of contaminants. Factor sampling costs into initial due diligence, especially when evaluating new suppliers.