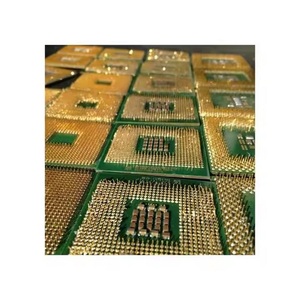

Scrap Computer Ram Producer

About scrap computer ram producer

Where to Find Scrap Computer RAM Producers?

Global supply of scrap computer RAM is primarily driven by industrial recyclers and specialized e-waste processors with in-house dismantling and sorting capabilities. Key suppliers operate integrated production lines focused on high-volume processing of end-of-life IT hardware, enabling consistent output of categorized RAM modules for downstream refining or component reuse. These producers typically source from enterprise decommissioning contracts, government auctions, and OEM take-back programs, ensuring a steady feedstock of standardized memory units.

Suppliers with dedicated RAM recovery lines offer advantages in material consistency and traceability. Processing involves automated demounting, PCB separation, and categorization by DDR generation (DDR1 to DDR4), capacity, and form factor (DIMM, SO-DIMM). This vertical integration allows for precise grading—critical for buyers engaged in gold recovery, semiconductor reclamation, or refurbishment. Regional clusters in Europe and Asia demonstrate strong logistics integration, supporting bulk shipments with minimal handling delays.

How to Choose Scrap Computer RAM Producers?

Effective supplier selection requires verification across technical, operational, and transactional dimensions:

Production Infrastructure

Confirm ownership of dedicated disassembly and sorting facilities. Suppliers advertising "own production line" typically maintain control over yield rates and material purity. Evaluate scale through minimum order thresholds: bulk pricing below $5/kg suggests industrial-scale operations, while per-piece pricing ($90/unit) indicates niche or hand-sorted inventory. Prioritize companies offering multi-kilogram or per-box lot options, which reflect higher throughput capacity.

Material Classification & Traceability

Assess product listings for specificity in composition:

- Clear differentiation between plastic-encapsulated and ceramic-based RAM modules

- Indication of gold content (e.g., “high-grade CPU scrap” vs. standard RAM boards)

- Segregation by weight class (per kg vs. per box) reflecting processing precision

Cross-reference listed main products (e.g., copper scrap, aluminum scrap) to verify metallurgical expertise relevant to precious metal extraction.

Transaction Reliability Indicators

Leverage response time as a proxy for operational discipline—suppliers answering within ≤2 hours demonstrate robust customer service infrastructure. While formal certifications (ISO, RoHS) are rarely disclosed in available data, consistent online transaction volume and repeat buyer metrics (where visible) serve as indirect quality signals. Favor partners with documented reorder behavior and short communication latency.

What Are the Leading Scrap Computer RAM Producers?

| Company Name | Main Products | RAM Pricing | MOQ Structure | Response Time | Product Range (Listings) | Specialization Notes |

|---|---|---|---|---|---|---|

| Audax GmbH | Aluminum Scrap, Plants Oil, Tractors | $0.75–$90 | 100 boxes / 1 kg / 1 pc | ≤7h | 5 | Broad MOQ flexibility; mixed pricing models suggest diversified inventory streams |

| SEANK HOT TRADE LIMITED | Engine Assembly, Copper Scrap, Iron Scrap | $10–$18 | 1,000 pieces | ≤18h | 5 | Focused on high-volume chip-level scrap; consistent per-unit pricing indicates automation |

| GOLDINGHAM CONTRACTS LIMITED | Plants Oil, Food Trucks, Tractors | $5–$18 | 12–1,000 kg | ≤2h | 5 | Lowest bulk price point; rapid response implies structured export operations |

| JAK Installationen GmbH | Copper Scrap, Aluminum Scrap, Pork | $0.55–$5.55 | 50–100 kg | ≤2h | 5 | Competitive mid-tier pricing; presence in metal scrap markets supports refining readiness |

| Sarl Bado 2 | Tractors, Loaders, Wood Pellets | $3–$2,500 | 100–300 kg / 1 ton | ≤3h | 4 | High-volume focus; ton-scale offers indicate large-scale processing infrastructure |

Performance Analysis

GOLDINGHAM CONTRACTS LIMITED and JAK Installationen GmbH lead in responsiveness (≤2h) and competitive bulk pricing, suggesting optimized internal workflows. SEANK HOT TRADE LIMITED targets high-volume buyers with uniform 1,000-piece MOQs, ideal for automated recycling lines. Sarl Bado 2 stands out with ton-level availability, indicating access to mass-scale e-waste feeds. Audax GmbH offers unusual pricing diversity, accommodating both small-scale testers and larger buyers. Despite varied core industries, all suppliers list RAM scrap alongside non-IT commodities, implying hybrid business models that may affect specialization depth.

FAQs

What determines scrap RAM pricing variability?

Price spreads reflect differences in DDR generation, gold yield potential, physical condition (intact vs. crushed), and packaging method. Higher prices per kilogram often correlate with ceramic substrates or known high-gold-content chips, whereas lower rates apply to mixed, unsorted batches.

What is the typical lead time for bulk orders?

Standard delivery windows range from 15–30 days after payment confirmation, depending on destination and shipment mode. Air freight reduces transit to 5–10 days but increases cost significantly for heavy materials.

Can suppliers provide material composition reports?

Formal assay reports are uncommon among listed suppliers. Buyers should request sample batches to conduct independent analysis of metal content and contamination levels before full procurement.

Is customization possible in sorting or grading?

Limited customization is available, such as DDR-type segregation or removal of non-RAM components. Full specification adherence requires direct negotiation and may incur additional processing fees.

How to mitigate quality risks when sourcing remotely?

Require pre-shipment sampling under video verification. Conduct third-party inspection at origin if ordering above 500 kg. Use secure payment methods with milestone releases tied to shipment and receipt milestones.