Bulk Product Boxes

Top sponsor listing

Top sponsor listing

1/19

1/19

1/18

1/18

CN

CN

1/20

1/20

1/14

1/14

CN

CN

1/22

1/22

1/12

1/12

1/51

1/51

1/19

1/19

CN

CN

1/16

1/16

About bulk product boxes

Where to Find Bulk Product Boxes Suppliers?

China remains a dominant hub for bulk product box manufacturing, with key production clusters in Guangdong, Shanghai, and Shandong provinces. These regions host vertically integrated packaging facilities that combine raw material processing, die-cutting, printing, and assembly under one roof, enabling cost-efficient scale production. Guangdong’s proximity to major ports like Shenzhen and Hong Kong facilitates rapid export logistics, while Shanghai and Qingdao offer mature industrial ecosystems supported by local paperboard and corrugated sheet suppliers.

The concentration of specialized manufacturers allows for optimized supply chains, reducing component procurement lead times by 20–30% compared to decentralized networks. Facilities typically maintain monthly production capacities exceeding 1 million units, supporting both high-volume standard orders and low-MOQ customized runs. Buyers benefit from flexible material sourcing—ranging from kraft paper and corrugated fiberboard to recyclable pulp and rigid board—with many suppliers operating ISO-certified quality management systems to ensure consistency in structural integrity and print accuracy.

How to Choose Bulk Product Boxes Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Material & Customization Capabilities

Assess whether suppliers support required specifications: material type (kraft, corrugated, recycled paper), weight (measured in gsm or ply count), dimensional tolerance (±1–2mm), and load capacity (tested up to 50kg for shipping boxes). Confirm access to digital mock-up tools, CMYK/spot color printing, lamination, foil stamping, embossing, and custom die-cutting. Suppliers should provide structural design files (PDF/DXF) for pre-production review.

Production & Quality Assurance

Prioritize manufacturers with documented quality control processes, including incoming material inspection, in-line monitoring, and batch testing for compression strength and edge crush test (ECT) values. While formal ISO 9001 certification is not universally listed, verify compliance through on-site audits or video tours. Evaluate minimum order quantity (MOQ) flexibility—ranging from 200 to 5,000 pieces across suppliers—and confirm lead times averaging 15–25 days post-approval of artwork and prototype.

Transaction Reliability Metrics

Analyze performance indicators such as on-time delivery rate (target ≥98%), response time (ideally ≤3 hours), and reorder rate (indicative of customer satisfaction). High-performing suppliers maintain online transaction volumes exceeding US $180,000 annually, reflecting consistent output and market demand. Use sample testing to validate durability, print fidelity, and assembly ease before scaling orders.

What Are the Best Bulk Product Boxes Suppliers?

| Company Name | Supplier Type | Main Materials | Customization Options | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

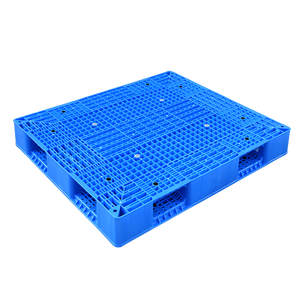

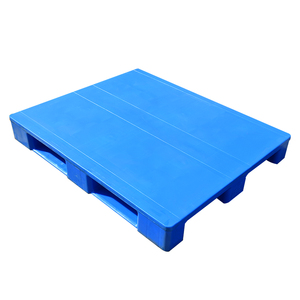

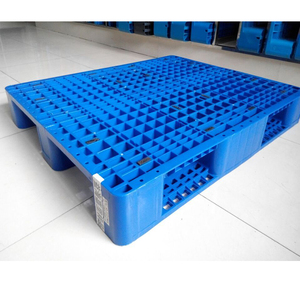

| Qingdao Enlightening Electromechanical Co., Ltd. | Custom Manufacturer | Pallets, Crates, Drums, Storage Bins | Color, thickness, weight, size, logo, graphic, capacity, load, packaging label | 100% | ≤2h | <15% | US $1.7M+ | 500–2,000 pcs |

| Shanghai Risen Packaging Co., Ltd. | Multispecialty Supplier | Corrugated, Kraft, Insulated Paper | Flat packed, lamination, foil, silk handle, CMYK printing, digital mock-up, insulation | 100% | ≤6h | 33% | US $210K+ | 200–500 pcs |

| Vision Pak Hk Limited | Multispecialty Supplier | Cardboard, Corrugated, Paper | Color, size, design, logo, packaging label, graphic | 100% | ≤3h | 44% | US $600K+ | 1–1,000 pcs |

| Shenzhen Feile Environmental Protection Packaging Technology Co., Ltd. | Custom Manufacturer | Kraft, Corrugated, Recyclable Cardboard | Color, size, logo, packaging label, graphic | 100% | ≤5h | 42% | US $180K+ | 500–5,000 pcs |

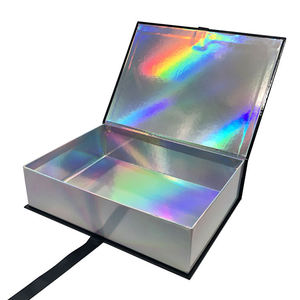

| Guangzhou Yuhe Biopak Co., Ltd. | Custom Manufacturer | Biodegradable Pulp, Magnetic Closure Board | Color, material, design, logo, foil, hot stamping, graphic | 98% | ≤1h | 28% | US $620K+ | 30–500 pcs |

Performance Analysis

Qingdao Enlightening Electromechanical leads in revenue volume (US $1.7M+), indicating large-scale production capability, though its low reorder rate suggests potential gaps in service retention. Vision Pak Hk Limited stands out with a 44% reorder rate and one-piece MOQ availability, ideal for startups and sampling. Shenzhen Feile and Shanghai Risen offer balanced customization depth with competitive pricing starting at $0.01 per unit. Guangzhou Yuhe Biopak specializes in eco-friendly molded pulp and luxury magnetic closure boxes, catering to premium markets. All top-tier suppliers achieve 100% on-time delivery except Guangzhou Yuhe (98%), with sub-6-hour average response times enhancing communication efficiency.

FAQs

How to verify bulk product box supplier reliability?

Cross-check declared production capabilities with available product range and transaction history. Request samples to assess material quality, print resolution, and structural rigidity. Evaluate responsiveness, packaging specification documentation, and willingness to provide digital prototypes or 3D renderings.

What is the typical sampling timeline?

Standard sample production takes 7–14 days, depending on complexity. Die-making for custom designs adds 3–5 days. Shipping via express courier averages 5–10 days internationally. Some suppliers offer free samples for qualified buyers, particularly when future volume commitments are indicated.

Can suppliers accommodate small orders?

Yes, several suppliers accept MOQs as low as 1–30 pieces, especially for non-standard or biodegradable designs. However, unit costs decrease significantly at 500+ quantities. Buyers should negotiate tiered pricing based on projected annual volume.

Do manufacturers support full customization?

Most custom manufacturers offer end-to-end design services, including artwork creation, structural engineering, and branding application (offset/digital printing, hot stamping). Clients can specify dimensions, window cutouts, handles, closures, and interior partitions. Digital mock-ups are typically provided within 48 hours of inquiry.

What are common materials used in bulk product boxes?

Primary materials include kraft paperboard (80–200gsm), single/double-wall corrugated cardboard, molded pulp, and rigid grey board. Eco-conscious suppliers use FSC-certified paper and water-based inks. Material selection depends on intended use—shipping, retail display, food packaging, or gift presentation.