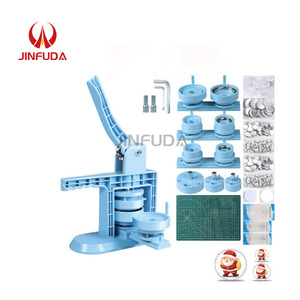

Button Maker 225

1/29

1/29

1/9

1/9

1/12

1/12

1/24

1/24

1/21

1/21

1/12

1/12

1/13

1/13

1/24

1/24

1/12

1/12

About button maker 225

Where to Find Button Maker 225 Suppliers?

China remains the central hub for button maker 225 manufacturing, with key production clusters in Guangdong, Zhejiang, and Tianjin offering specialized capabilities. Shenzhen and Yiwu serve as primary centers for small-scale and DIY-oriented button press machines, leveraging dense networks of component suppliers and rapid prototyping facilities. Tianjin and Hangzhou host more industrial-grade equipment producers, integrating pneumatic systems and electromechanical assembly lines for high-volume garment accessory production.

These regional ecosystems enable vertically integrated supply chains—spanning mold fabrication, metal stamping, and plastic injection—reducing material procurement cycles by 20–30%. Buyers benefit from localized logistics, with average lead times ranging from 15 to 30 days for standard orders. Cost efficiency is further enhanced through economies of scale, with unit prices for manual button makers starting as low as $19/set. The concentration of technical labor and export-focused infrastructure supports both mass production (MOQs from 1–5 sets) and customized configurations tailored to niche craft or industrial applications.

How to Choose Button Maker 225 Suppliers?

Effective supplier selection requires systematic evaluation across three core dimensions:

Technical Capability Verification

Assess whether suppliers offer compatible machine types—manual hand presses for craft use versus semi-automatic or pneumatic models for industrial throughput. Confirm compatibility with standard button sizes (e.g., 25mm, 58mm, 75mm) and materials (metal, plastic, fabric). For customization needs, verify support for die modifications, logo embossing, and packaging design. Suppliers with in-house tooling and R&D capacity are better positioned to accommodate non-standard requests.

Production and Quality Metrics

Evaluate operational performance using verifiable indicators:

- On-time delivery rate ≥95% indicates reliable logistics execution

- Reorder rates above 20% reflect customer satisfaction and product consistency

- Response time under 10 hours ensures efficient communication

Prioritize suppliers with documented quality control processes, especially those indicating compliance with international standards such as CE or ISO 9001, even if not explicitly stated.

Transaction Security and Support

Favor suppliers offering transaction protection mechanisms and transparent order tracking. Analyze online revenue benchmarks (e.g., >US$100,000 annually) as a proxy for market presence and service maturity. Pre-shipment inspection rights and sample testing should be negotiated upfront, particularly when procuring higher-value automated units priced above $500.

What Are the Best Button Maker 225 Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Min. Order Flexibility |

|---|---|---|---|---|---|---|---|---|

| Talent (Tianjin) Electronics Co., Ltd. | Tianjin, CN | Custom Manufacturer | US $330,000+ | 96% | ≤10h | <15% | Yes | 1 set |

| Shenzhen Hde Garment Accessories Co., Ltd. | Shenzhen, CN | Not Specified | US $40,000+ | 97% | ≤4h | 22% | Limited | 1–2 sets |

| Yiwu Chuxin Technology Co., Ltd. | Yiwu, CN | Not Specified | US $10,000+ | 85% | ≤1h | 20% | Limited | 1 piece |

| Hangzhou Anysew Garment Equipment Co., Ltd. | Hangzhou, CN | Multispecialty Supplier | US $70,000+ | 100% | ≤7h | 22% | Yes | 1–5 sets |

| Guangzhou Yinghe Electronic Instruments Co., Ltd. | Guangzhou, CN | Multispecialty Supplier | US $1,500,000+ | 97% | ≤4h | 43% | Yes | 1 unit |

Performance Analysis

Guangzhou Yinghe stands out with the highest reorder rate (43%) and annual online revenue (US$1.5M+), indicating strong market trust and repeat business—key markers of product reliability and service consistency. Hangzhou Anysew achieves perfect on-time delivery (100%), making it a preferred partner for time-sensitive industrial procurement. Talent (Tianjin) offers deep customization across materials, shapes, and packaging but has a lower reorder rate, suggesting potential gaps in post-sale experience. Yiwu Chuxin leads in responsiveness (≤1h) and low MOQ flexibility, ideal for startups or small-batch buyers testing product viability. Shenzhen Hde balances affordability and reliability, with competitive pricing and fast response times.

FAQs

How to verify button maker 225 supplier reliability?

Cross-check delivery performance, response time, and reorder metrics against historical transaction data. Request evidence of quality control procedures, machine testing protocols, and material sourcing transparency. For high-volume contracts, conduct virtual factory audits to assess production lines and inventory management practices.

What is the typical sampling timeline?

Standard samples for manual button makers can be produced within 7–14 days. Customized units with specific dies or branding require 15–25 days. Air shipping adds 5–10 days for international delivery. Some suppliers offer free samples for future bulk commitments.

Can suppliers ship button maker 225 globally?

Yes, most suppliers support worldwide shipping via express, air, or sea freight. Confirm Incoterms (FOB, CIF) during negotiation. Industrial models may require voltage adjustments (110V/220V) for compatibility in North American or European markets.

Do manufacturers provide free samples?

Free samples are uncommon for machinery, but some suppliers waive fees for qualified buyers committing to minimum volumes. Sample costs typically range from 30–70% of unit price and may be deducted from future orders.

How to initiate customization requests?

Submit detailed specifications including button diameter, material type (iron, plastic, fabric), pressing force requirements, and desired output capacity. For branding, provide vector artwork for molds or labels. Reputable suppliers will respond with technical feasibility assessments and prototype timelines within 72 hours.