C Shape Roll Forming Machine Supplier

Top sponsor listing

Top sponsor listing

1/9

1/9

1/1

1/1

1/3

1/3

1/3

1/3

1/1

1/1

1/3

1/3

1/11

1/11

1/3

1/3

CN

CN

1/3

1/3

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/19

1/19

0

0

About c shape roll forming machine supplier

Where to Find C Shape Roll Forming Machine Suppliers?

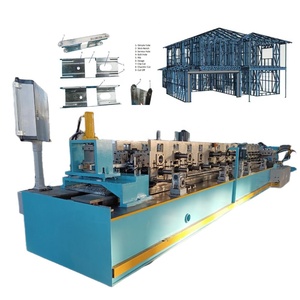

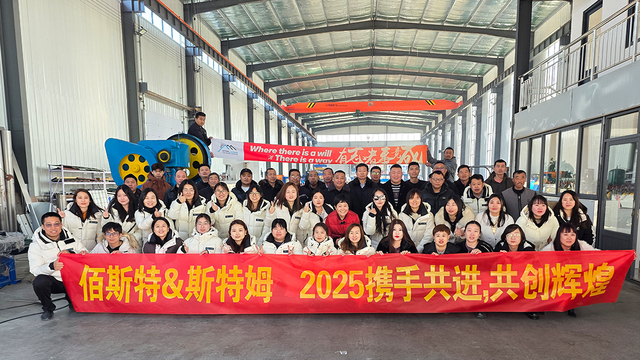

China remains the global epicenter for c shape roll forming machine manufacturing, with key production hubs concentrated in Jiangsu, Tianjin, and Henan provinces. These regions host vertically integrated industrial ecosystems that combine precision engineering, steel processing, and automation expertise. Jiangsu’s Wuxi district specializes in high-precision roll forming systems, leveraging proximity to Shanghai’s logistics network for efficient export operations. Tianjin-based manufacturers benefit from access to cold-rolled steel supply chains, reducing material procurement lead times by 15–20%. Meanwhile, Henan’s Zhengzhou cluster focuses on cost-effective automated solutions tailored for mid-volume producers.

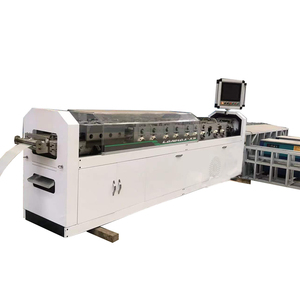

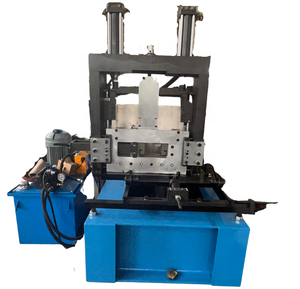

The regional infrastructure supports rapid prototyping and scalable production, with most suppliers operating facilities exceeding 3,000m² and maintaining in-house CNC machining, welding, and PLC programming capabilities. Buyers can expect average lead times of 30–45 days for standard configurations, with localized component sourcing enabling 20–30% cost advantages over European or North American manufacturers. The ecosystem also facilitates customization flexibility, including integration with pre-punching units, multi-profile changers, and galvanized steel compatibility.

How to Choose C Shape Roll Forming Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Confirm adherence to international quality standards such as ISO 9001. For markets requiring regulatory compliance (EU, USA), verify CE marking and functional safety documentation. Request test reports for critical subsystems—particularly drive trains, roller dies, and control panels—to ensure durability under continuous operation.

Production Capability Verification

Assess core manufacturing capacity through the following indicators:

- Minimum factory area of 3,000m² to support assembly lines and inventory storage

- In-house engineering teams capable of custom profile design and tooling fabrication

- Integrated CNC processing and robotic welding stations to ensure dimensional accuracy

Cross-reference declared capabilities with verified on-time delivery performance (target ≥95%) and response time metrics (ideally ≤1 hour).

Transaction Security & After-Sales Support

Prioritize suppliers offering structured warranty terms (minimum 12 months) and remote diagnostics via PLC-based monitoring systems. Utilize secure payment mechanisms tied to shipment milestones. Evaluate after-sales responsiveness through historical reorder rates—values above 50% indicate strong customer retention and service reliability. Pre-shipment inspection protocols should include no-load testing, alignment verification, and material feed calibration.

What Are the Best C Shape Roll Forming Machine Suppliers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|

| Sussman Machinery (Wuxi) Co., Ltd. | Steel Frame & Purlin Machines, Tile Making Machinery | US $670,000+ | 100% | 100% | ≤1h | Material, thickness, profile, logo, packaging, color, graphic | $8,000–$36,500 |

| Tianjin Ironstar Industry Co., Ltd. | Light Steel Framing, Roof Truss, Purlin Machines | US $1,800,000+ | 100% | 50% | ≤1h | Material, size, logo, packaging, label, graphic, color | $8,000–$36,500 |

| Steelmama Machinery Inc | Full-Automatic C-Profile, Galvanized Steel Purlin Machines | Data Unavailable | Not Specified | Not Specified | ≤1h | Limited Public Data | $13,900–$19,000 |

| Zhengzhou Linran Equipment Co., Ltd. | Automatic C-Shape, PLC-Controlled Channel Machines | US $90,000+ | 100% | 50% | ≤1h | Material, thickness, size, logo, packaging | $6,550–$26,500 |

| Hangzhou Willing International Co., Ltd. | Full-Automatic CZ-Purlin, Interchangeable Profile Machines | Data Unavailable | 100% | Not Specified | ≤3h | Profile configuration, automation level | $32,000–$76,000 |

Performance Analysis

Sussman Machinery stands out with a 100% reorder rate and comprehensive customization portfolio, indicating exceptional customer satisfaction and technical adaptability. Tianjin Ironstar leads in online sales volume (over US $1.8 million), reflecting strong market penetration and consistent output quality. Zhengzhou Linran offers competitive entry-level pricing starting below $7,000 while maintaining verified on-time delivery. Hangzhou Willing targets premium applications with high-capacity, fully automatic systems priced above $70,000, suitable for large-scale construction material producers. Steelmama Machinery shows fast response capability but lacks verifiable performance metrics, suggesting higher due diligence requirements before engagement.

FAQs

How to verify c shape roll forming machine supplier reliability?

Cross-validate ISO certifications and CE declarations with issuing bodies. Request factory audit reports or video walkthroughs confirming CNC machining centers, die manufacturing units, and final assembly lines. Analyze transaction history for consistency in delivery performance and post-sale support.

What is the typical lead time for c shape roll forming machines?

Standard models are typically delivered within 30–45 days after order confirmation. Customized systems with integrated punching or multi-profile changers may require 50–65 days depending on complexity.

Do suppliers offer customization for different steel thicknesses and profiles?

Yes, most leading suppliers support material thickness ranges from 0.4mm to 3.0mm and can engineer rollers for custom C-section dimensions (e.g., 80–350mm depth). CAD/CAM-based design services are commonly provided for new profile development.

Can c shape roll forming machines process galvanized steel coils?

Yes, all major suppliers configure machines for galvanized, pre-painted, and cold-rolled steel substrates. Ensure coating compatibility is specified during inquiry to prevent edge cracking or roller wear issues.

Is remote technical support available after installation?

Reputable suppliers offer PLC-based remote diagnostics, instructional videos, and live troubleshooting via WhatsApp or WeChat. Some provide on-site commissioning support at additional cost, particularly for automated high-speed lines.