C Section C Frame Roll Forming Machine Factories

Top sponsor listing

Top sponsor listing

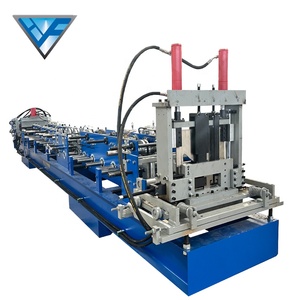

1/47

1/47

CN

CN

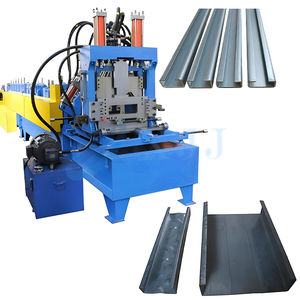

1/17

1/17

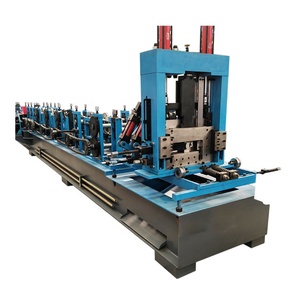

1/13

1/13

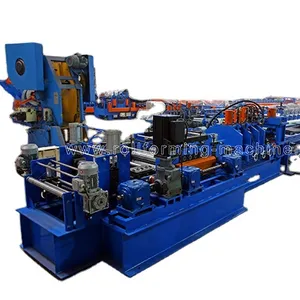

1/22

1/22

1/3

1/3

1/25

1/25

1/9

1/9

1/27

1/27

1/34

1/34

CN

CN

1/8

1/8

1/3

1/3

1/20

1/20

CN

CN

1/26

1/26

About c section c frame roll forming machine factories

Where to Find C Section C Frame Roll Forming Machine Suppliers?

China remains the global epicenter for roll forming machinery production, with key manufacturing clusters concentrated in Hebei and Fujian provinces. The Cangzhou region in Hebei hosts a dense network of metal processing equipment manufacturers specializing in cold roll forming systems for structural profiles such as C-sections and C-frames. This industrial zone benefits from proximity to major steel producers, reducing raw material lead times by 20–30% compared to offshore alternatives. Xiamen in Fujian has emerged as a hub for export-oriented machinery firms, leveraging port logistics and integrated supply chains for international distribution.

These regions feature vertically aligned production ecosystems where suppliers manage full cycles—from decoiler integration to punching, roll forming, and cutting systems—within single facilities. This vertical integration enables faster prototyping (typically 15–25 days) and supports customization without significant cost premiums. Buyers benefit from scalable production capacity, with standard machine delivery timelines averaging 30–45 days. Localized component sourcing reduces overall manufacturing costs by 18–25% versus Western or Southeast Asian producers, making these zones ideal for both bulk procurement and engineered-to-order solutions.

How to Choose C Section C Frame Roll Forming Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance and Design Capability

Confirm adherence to internationally recognized quality standards such as ISO 9001. For shipments to regulated markets (EU, North America), verify CE marking and compliance documentation. Evaluate engineering depth through availability of design drawings, 3D modeling, and profile simulation tools. Suppliers should provide detailed specifications covering roller count, shaft diameter, motor power, and control systems (PLC/HMI).

Production Infrastructure Assessment

Assess physical capabilities using the following benchmarks:

- Minimum factory area exceeding 3,000m² to ensure dedicated assembly lines

- In-house machining capacity including CNC lathes, milling, and heat treatment for critical components

- Dedicated R&D or engineering departments capable of modifying feed width (80–300mm), material thickness (0.3–4.0mm), and output speed (up to 40m/min)

- Integration of hydraulic cutting, auto-packing, and multi-layer stackers as value-added options

Cross-reference on-time delivery performance (>95%) with reorder rates to gauge reliability and customer satisfaction.

Procurement Risk Mitigation

Utilize secure payment mechanisms such as escrow services until final inspection clearance. Request sample units or factory videos to validate build quality. Prioritize suppliers offering customization logs, material traceability reports, and post-delivery technical support. Conduct virtual audits to confirm presence of testing protocols for alignment accuracy and dimensional consistency of formed sections.

What Are the Best C Section C Frame Roll Forming Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Product Range (Price Span) | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $990,000+ | 92% | ≤2h | 100% | $9,988 – $36,000 | Width, thickness, color, logo, double-layer, gearbox, rollers, profile length, feeding system |

| Tianjin Haixing Imp & Exp Co., Ltd. | Tianjin, CN | Custom Manufacturer | US $1,100,000+ | 100% | ≤1h | 63% | $6,500 – $29,999 | Color, shape, thickness, profile, packaging, label, size, design, logo, model |

| Xiamen HF Roll Machinery Co., Ltd. | Xiamen, CN | Custom Manufacturer | US $90,000+ | 100% | ≤9h | 100% | $7,800 – $82,800 | Changeable C/Z profiles, fully automatic operation, purlin configuration |

| Botou Huayang Roll Forming Machinery Co.,Ltd | Botou, CN | Custom Manufacturer | US $260,000+ | 100% | ≤3h | 33% | Data not available | Conveyor types, color, thickness, mold, weight, packaging, label, layer, hydraulic specs, dimensions |

| Cangzhou Xinjiujun Machinery Equipment Manufacturing Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $20,000+ | 100% | ≤2h | <15% | $8,001 – $15,000 | Material, size, logo, packaging, graphic, color |

Performance Analysis

Cangzhou Forward demonstrates strong technical versatility with high reorder frequency and broad customization depth, despite a slightly lower on-time delivery rate. Tianjin Haixing leads in responsiveness and transaction volume, indicating robust export operations and customer service efficiency. Xiamen HF offers premium-tier machines up to $82,800, targeting high-automation applications with fully automatic C/Z purlin lines, backed by perfect delivery and repeat order records. Botou Huayang provides extensive configurability across downstream handling systems but lacks published pricing data, suggesting project-based quoting. Cangzhou Xinjiujun serves budget-conscious buyers with competitive entry-level pricing, though low reorder rates may indicate limited after-sales engagement. Buyers seeking precision engineering and scalability should prioritize suppliers with documented automation integration and PLC-controlled systems.

FAQs

How to verify c section roll forming machine supplier reliability?

Validate certifications (ISO, CE) through official registries and request machine test reports, including alignment tolerance (±0.5mm) and straightness verification. Analyze supplier response patterns, reorder rates, and delivery consistency. Conduct video walkthroughs of active production lines to confirm claimed capabilities.

What is the typical lead time for customized roll forming machines?

Standard configurations ship within 30 days. Custom models requiring modified roller sets, extended runouts, or integrated punching stations take 40–60 days depending on complexity. Allow additional time for third-party inspections and export documentation.

Do suppliers offer international shipping and installation support?

Yes, most established exporters provide FOB or CIF shipping terms with container loading supervision. Some offer technician dispatch services for overseas commissioning at an additional cost. Confirm inclusion of user manuals, spare parts kits, and electrical compatibility (voltage/frequency) prior to order placement.

Can I request a sample or prototype before full-scale ordering?

While full-machine sampling is uncommon due to size and cost, suppliers typically provide formed profile samples (C-channel sections) free of charge or at minimal cost. These are produced using client-specified material grade and thickness to verify cross-sectional accuracy and edge quality.

What level of customization is available for C frame roll forming lines?

Key customizable parameters include coil width (38–300mm), material thickness (0.3–4.0mm), yield strength (235–550 MPa), output speed (10–40 m/min), roller station count (12–24 stands), and automation level (manual, semi-auto, fully automatic with stacking). Additional options include digital counters, servo feeding, hole-punching modules, and SCADA monitoring interfaces.