C Z U Roll Forming Machine Factory

About c z u roll forming machine factory

Where to Find C Z U Roll Forming Machine Suppliers?

China remains the global epicenter for C, Z, and U channel roll forming machine production, with key manufacturing clusters concentrated in the Hebei province—particularly in Cangzhou and Botou. These regions host vertically integrated industrial ecosystems specializing in light gauge steel framing equipment, benefiting from proximity to raw material suppliers and cold-rolled steel mills. This localization reduces component procurement lead times by 20–30% and lowers logistics costs for export shipments via Tianjin Port, one of North China’s largest maritime gateways.

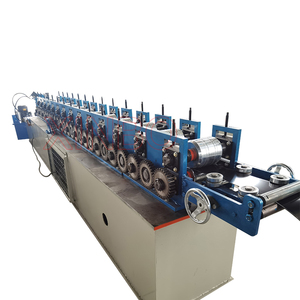

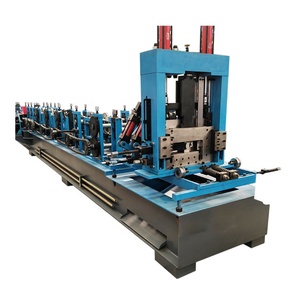

The Cangzhou-Botou corridor is home to over 150 dedicated roll forming machinery manufacturers, many operating their own production lines for molds, rollers, and hydraulic systems. This integration enables rapid prototyping and customization, with standard machine delivery timelines averaging 30–45 days. Buyers gain access to a mature supply base offering scalable output—from compact semi-automatic units for small workshops to fully automated lines capable of 20–30 meters per minute throughput. The region's specialization in construction-grade profile forming ensures deep technical expertise in C/Z purlin, stud, track, and roofing applications.

How to Choose C Z U Roll Forming Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical & Production Capability

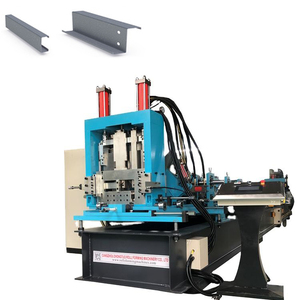

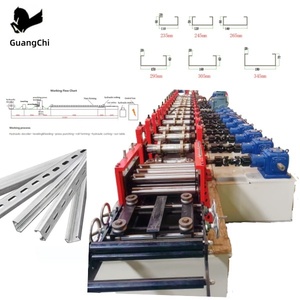

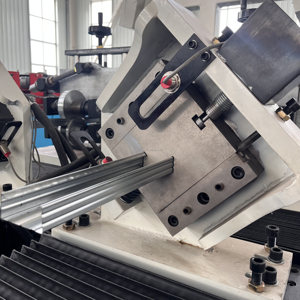

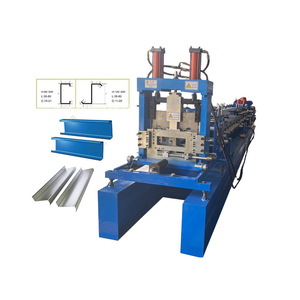

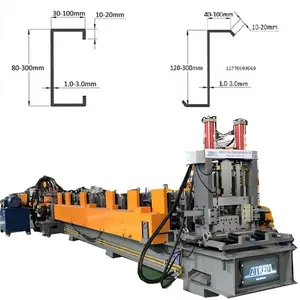

Verify that suppliers maintain in-house engineering teams and CNC machining facilities for roller die fabrication. Key indicators include control over mold precision (±0.1mm tolerance), use of laser welding for shaft alignment, and integration of PLC automation for consistent profile accuracy. Prioritize manufacturers specifying material thickness ranges (typically 0.4–3.0mm) and coil width compatibility (80–300mm) aligned with your production needs.

Quality Assurance & Compliance

While ISO 9001 certification is not universally listed, assess quality through verifiable performance metrics: on-time delivery rates exceeding 95%, documented response times under 2 hours, and product conformity backed by pre-shipment inspection protocols. For markets requiring regulatory compliance, confirm CE marking availability and electrical safety standards (e.g., 380V/50Hz configurations).

Customization & After-Sales Support

Evaluate flexibility in design modifications—including hole punching patterns, multi-profile changeover systems, and hydraulic decoiler integration. Confirm whether suppliers provide layout drawings, 3D modeling, and operational training. Post-installation support, such as remote troubleshooting and spare parts availability, should be contractually defined prior to order placement.

What Are the Best C Z U Roll Forming Machine Suppliers?

| Company Name | Location | Online Revenue | On-Time Delivery | Response Time | Reorder Rate | Price Range (USD) | Key Features |

|---|---|---|---|---|---|---|---|

| Cangzhou Zhongtuo International Trade Co., Ltd. | Cangzhou, CN | US $4.6M+ | 100% | ≤2h | 37% | $11,500–40,000 | Quick-size change; hydraulic decoiler; automatic stacker; multi-profile capability |

| Botou Kefa Roll Forming Machine Co., Ltd. | Botou, CN | US $100K+ | 100% | ≤2h | 33% | $13,000–32,000 | Automatic quick-change system; high-precision rollers; customizable logo/packaging |

| CANGZHOU HAUAN ROLL FORMING MACHINERY CO., LTD. | Cangzhou, CN | US $220K+ | 75% | ≤1h | 55% | $7,530–26,888 | Energy-efficient design; laser-welded molds; hydraulic operation options |

| Botou Toppo Machinery Co., Ltd. | Botou, CN | US $8K+ | 100% | ≤4h | 16% | $7,630–75,591 | High-precision forming; affordable entry-level models; customization available |

| Henan Dingkou Industrial Co., Ltd. | Henan, CN | US $160K+ | 100% | ≤8h | 40% | $6,900–38,000 | Broad product range; cost-effective solutions; focus on ceiling and wall systems |

Performance Analysis

Cangzhou Zhongtuo leads in scale and technological breadth, offering advanced features like automatic IBR roofing lines and slitting systems, supported by strong reorder volume. Botou-based Kefa and Toppo provide competitive pricing with solid delivery reliability, though Toppo’s lower reorder rate suggests potential gaps in post-sale service. Hauan stands out for fast responsiveness and high customer retention (55% reorder rate), despite a below-average on-time delivery score. Henan Dingkou offers the widest price dispersion, indicating adaptability across budget segments but potentially inconsistent quality control across product tiers. Suppliers with comprehensive customization tags—such as hydraulic configuration, thickness adjustment, and graphic design integration—demonstrate stronger engineering support for specialized applications.

FAQs

What is the typical MOQ and lead time for C Z U roll forming machines?

Minimum order quantity is typically 1 set across all major suppliers. Lead times range from 25–45 days depending on automation level and customization requirements. Standard models are often ready for shipment within 30 days.

Can suppliers customize machine specifications?

Yes, most suppliers offer full customization including feeding width (80–300mm), material thickness (0.4–3.0mm), punching patterns, motor voltage (380V/50Hz standard), and control systems (PLC brands). Technical drawings and layout plans are usually provided before production begins.

Do these manufacturers provide certifications?

While explicit ISO or CE certification claims are not always stated, many suppliers comply with international safety and electrical standards upon request. Buyers should formally request compliance documentation during negotiation, especially for EU or North American market imports.

How are machines packaged and shipped?

Machines are typically disassembled, treated with anti-rust coating, and packed in seaworthy plywood crates. FOB terms are common, with primary loading ports in Tianjin or Qingdao. Full container (20ft or 40ft) shipments are standard for single-machine orders.

Is installation and training support available?

Most suppliers offer remote guidance via video or manuals. On-site installation and operator training may be available at additional cost—confirm availability and associated fees upfront. Some providers include basic troubleshooting support for 12 months post-delivery.