Automatic Roll Forming Machine Factory

CN

CN

1/9

1/9

CN

CN

CN

CN

1/3

1/3

CN

CN

1/9

1/9

1/30

1/30

1/19

1/19

CN

CN

1/9

1/9

1/1

1/1

0

0

1/3

1/3

CN

CN

1/8

1/8

About automatic roll forming machine factory

Where to Find Automatic Roll Forming Machine Factory Suppliers?

China remains the global epicenter for automatic roll forming machine manufacturing, with key industrial hubs concentrated in Hebei and Henan provinces. These regions host vertically integrated production ecosystems that combine precision engineering, sheet metal processing, and automation assembly under one roof. Hebei’s Shijiazhuang and Cangzhou clusters benefit from proximity to major steel producers, enabling raw material cost savings of 15–20% compared to offshore alternatives. Meanwhile, Henan-based manufacturers leverage mature supply chains for servo drives, PLC systems, and hydraulic components, ensuring consistent component quality and faster turnaround.

The presence of dedicated industrial zones allows suppliers to maintain end-to-end control—from coil feeding systems to final cutting units—within compact geographic radii. This integration supports rapid prototyping, scalable batch production, and efficient customization. Buyers typically experience lead times of 30–45 days for standard configurations, with express production options available for urgent orders. The region’s logistics infrastructure facilitates direct export via Tianjin or Qingdao ports, reducing shipping delays and container handling risks.

How to Choose Automatic Roll Forming Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certification

Verify adherence to international standards such as ISO 9001 for quality management and CE marking for electrical and mechanical safety compliance. For markets in Europe or North America, ensure machines meet relevant machinery directives (e.g., EU Machinery Directive 2006/42/EC). Request documentation on motor efficiency ratings, control system specifications (Siemens, Mitsubishi, or Delta), and material yield strength testing protocols.

Production Capability Assessment

Evaluate core manufacturing capacity through objective indicators:

- Minimum factory area exceeding 3,000m² to support full production lines

- In-house CNC machining, welding, and surface treatment capabilities

- Dedicated R&D teams focused on automation integration and process optimization

Cross-reference online performance metrics such as on-time delivery rates (>95%) and reorder frequency to assess reliability and customer satisfaction.

Customization & Quality Assurance

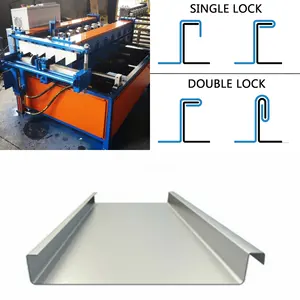

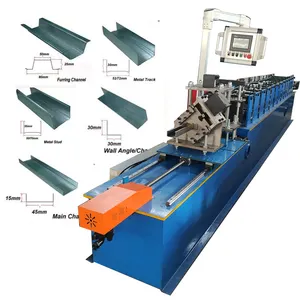

Confirm the supplier offers configurable parameters including material thickness (0.3–1.2mm range), forming speed (up to 30m/min), and profile complexity (C/Z/purlin, IBR, trapezoidal, etc.). Insist on pre-shipment inspection protocols, including no-load operation tests, dimensional accuracy checks, and alignment verification. Video audits of assembly lines can validate process discipline and equipment calibration practices.

What Are the Best Automatic Roll Forming Machine Suppliers?

| Company Name | Location | Verification Status | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shijiazhuang Yingyee Machinery Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $2,800,000+ | 100% | 100% | ≤1h | $21K–$170K | Color, material, size, logo, packaging, graphic |

| Botou Kefa Roll Forming Machine Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $110,000+ | 100% | 33% | ≤2h | $5.8K–$30K | Color, material, size, thickness, logo, packaging, graphic |

| HENAN SUPERB MACHINERY CO., LTD. | Henan, CN | Not Verified | US $190,000+ | 93% | <15% | ≤3h | $1.9K–$7.5K | Color, material, size, logo, packaging, graphic |

| Tangshan Shuoen International Trade Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $1,000,000+ | 100% | 42% | ≤2h | $1.5K–$7K | Tile shape, color, thickness, profile, width, raw materials, sheet style, logo, graphic |

| Cangzhou Solan Machinery Manufacturing Co., Ltd. | Hebei, CN | Custom Manufacturer | US $30,000+ | 100% | 100% | ≤2h | $7.5K–$12K | Color, size, logo, packaging, graphic |

Performance Analysis

Shijiazhuang Yingyee stands out with a 100% reorder rate and sub-one-hour response time, indicating high service responsiveness and product consistency. Its wide price range ($21,000–$170,000) reflects capability in both mid-tier and high-end automated systems, including perforated cable tray and downpipe solutions. Tangshan Shuoen offers extensive customization depth, particularly for roofing profiles and tile styles, supported by strong transaction volume (US $1M+ annual revenue).

Cangzhou Solan demonstrates niche specialization in metal frame and keel forming, with uniform pricing and consistent delivery performance. Botou Kefa provides broader application coverage—from insulation panels to steel C-purlins—at competitive price points, though its lower reorder rate suggests room for improvement in post-sale engagement. HENAN SUPERB offers entry-level automation at aggressive price points (as low as $1,900), but longer response times and a 93% on-time delivery rate warrant due diligence before large-scale procurement.

FAQs

How to verify automatic roll forming machine supplier reliability?

Validate certifications (ISO, CE) through official registries and request machine-specific test reports, including PLC diagnostics, roll alignment data, and motor load curves. Conduct virtual factory audits to observe CNC machining centers and assembly workflows. Prioritize suppliers with documented quality control checkpoints and third-party inspection records.

What is the typical MOQ and lead time?

Standard minimum order quantity is 1 set, allowing buyers to test machine performance before scaling. Lead times average 30–45 days post-deposit, depending on customization level. Simple single-layer roofing machines may ship within 25 days, while complex dual-head or high-speed systems require up to 60 days.

Can suppliers customize machine specifications?

Yes, most suppliers offer full configurability in material thickness (0.3–1.5mm), coil width (up to 1,250mm), forming speed (15–30m/min), and drive systems (servo vs. hydraulic). Custom tooling design, PLC interface language, and output stacking mechanisms are commonly adjustable based on client requirements.

Do suppliers provide after-sales technical support?

Reputable manufacturers offer remote troubleshooting via video guidance, English-language operation manuals, and spare parts supply chains. Some extend on-site commissioning services or training programs for operators, particularly for high-value installations exceeding $50,000.

How are machines packaged and shipped internationally?

Machines are typically secured in seaworthy plywood crates with anti-corrosion coating and moisture barriers. FOB terms are standard, with optional CIF arrangements available. Shipping via 20' or 40' HQ containers accommodates one to three machines per shipment, depending on size and configuration.