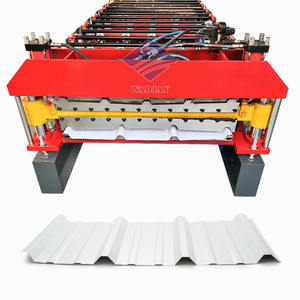

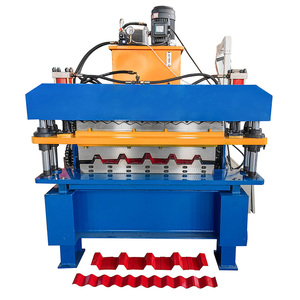

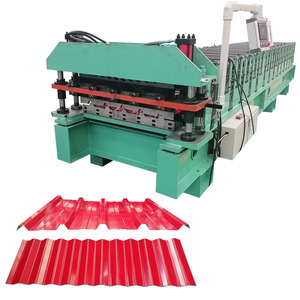

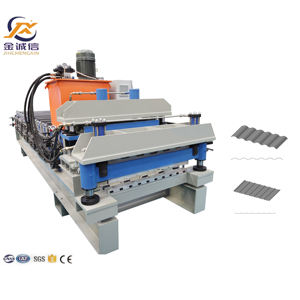

Customized Automic Double Layer Roll Forming Machine

1/13

1/13

1/3

1/3

1/9

1/9

1/19

1/19

1/17

1/17

1/22

1/22

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

1/25

1/25

1/25

1/25

1/9

1/9

1/3

1/3

About customized automic double layer roll forming machine

Where to Find Customized Atomic Double Layer Roll Forming Machine Suppliers?

China remains the dominant hub for roll forming machinery production, with key manufacturing clusters in Tianjin, Hebei, and Henan provinces. These regions host vertically integrated industrial ecosystems that combine cold roll forming expertise, precision machining, and advanced automation engineering. Tianjin and Botou (Hebei) are particularly renowned for metal sheet processing equipment, offering access to high-capacity fabrication facilities and proximity to major steel suppliers, reducing material lead times by 15–20% compared to offshore alternatives.

The concentration of component manufacturers—ranging from servo drives to hydraulic cutting units—within 50km radii enables rapid prototyping and scalable production. Buyers benefit from localized supply chains that support both standard configurations and fully customized double layer roll forming systems. Typical advantages include lead times of 30–45 days for automated models, cost savings of 25–35% over Western-built machines, and extensive flexibility in feed width, profile design, and control system integration.

How to Choose Customized Atomic Double Layer Roll Forming Machine Suppliers?

Procurement decisions should be guided by structured evaluation criteria focused on technical capability, quality assurance, and transaction reliability:

Technical Compliance & Certifications

Verify CE certification as a baseline requirement for international safety standards, especially for electrical and mechanical subsystems. While ISO 9001 is not universally listed, prioritize suppliers demonstrating documented quality management processes. Request validation of motor specifications (e.g., 380V/50Hz), PLC brands (Siemens, Delta, or Mitsubishi), and roller shaft hardness (HRC 58–62) to ensure durability under continuous operation.

Production and Customization Capability

Assess supplier capacity through the following indicators:

- Proven ability to customize critical parameters: material thickness (0.3–0.8mm), coil width (up to 1,250mm), and output speed (10–20m/min)

- In-house design teams capable of generating technical drawings and 3D renderings based on client profiles

- Range of available customization options including color coding, embossing, bending sequences, and packaging configurations

Cross-reference product listings with response times and reorder rates to assess operational responsiveness and customer retention.

Transaction Security and Quality Assurance

Utilize secure payment mechanisms such as escrow services to mitigate risk during initial procurement. Prioritize suppliers with verifiable on-time delivery performance (target ≥98%) and documented after-sales service policies. Conduct pre-shipment inspections or request factory videos to validate assembly line practices. Sample testing is strongly advised—evaluate formed panel dimensional accuracy, edge consistency, and weld integrity before full-scale orders.

What Are the Best Customized Atomic Double Layer Roll Forming Machine Suppliers?

| Company Name | Location | Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD) | Customization Scope |

|---|---|---|---|---|---|---|---|---|

| Tianjin Haixing Imp & Exp Co., Ltd. | Tianjin, CN | Custom Manufacturer | US $1,100,000+ | 100% | ≤1h | 58% | $7,200–19,800 | Color, shape, thickness, profile, length, label, material, size, design, width, logo, model |

| Tangshan Shuoen International Trade Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $1,000,000+ | 100% | ≤2h | 42% | $2,900–6,900 | Tile shape, color, thickness, profile, packaging, raw materials, sheet style, glazed type, size, width, logo, graphic, layer count |

| HAIXING (TIANJIN) INTELLIGENT EQUIPMENT CO., LTD | Tianjin, CN | Multispecialty Supplier | US $630,000+ | 100% | ≤1h | 33% | $6,500–33,571 | Color, material, size, feed width, design, logo, sheet type, packaging, label, graphic, parameters |

| Zhengzhou Hokang Machinery Co., Ltd. | Henan, CN | Multispecialty Supplier | US $280,000+ | 100% | ≤1h | 28% | $3,800–9,800 | Shutter door, color, thickness, pattern, mold, packaging, bending, size, design, drawing, logo, graphic |

| Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd. | Hebei, CN | Manufacturer | US $20,000+ | 100% | ≤4h | - | $8,000–14,500 | Limited customization; focus on tile making, wall panels, corrugated sheets |

Performance Analysis

Tianjin-based suppliers exhibit strong export performance, with Haixing and HAIXING (Tianjin) demonstrating high reorder rates, sub-2-hour response times, and broad customization capabilities. Tangshan Shuoen stands out for competitive pricing and robust transaction volume, indicating scalability despite lower average unit prices. Zhengzhou Hokang offers mid-range solutions with specialized options for shutter door and trapezoidal profiles, while Botou Shitong provides reliable entry-level automation at higher price points, suggesting a focus on durability over cost leadership. Suppliers with revenue exceeding US $1 million demonstrate consistent market demand and logistical maturity for global shipping.

FAQs

How to verify customized double layer roll forming machine supplier reliability?

Validate certifications (CE, ISO) through official databases or third-party inspection reports. Request references or case studies for similar projects. Analyze customer reviews focusing on post-installation support, control system usability, and long-term wear resistance of rollers and cutters.

What is the typical lead time for custom roll forming machines?

Standard delivery ranges from 30 to 45 days after deposit confirmation. Complex customizations involving multi-stage bending, integrated punching, or special drive systems may extend timelines to 60 days. Expedited builds can sometimes be arranged for an additional fee.

Do suppliers offer OEM/ODM services?

Yes, most suppliers provide OEM labeling, branded HMI interfaces, and tailored machine enclosures. ODM services include full design adaptation based on client-specified panel profiles, often supported by CAD/CAM modeling within 72 hours of inquiry.

What are common customization parameters?

Key adjustable features include coil material (galvanized, aluzinc, color-coated steel), thickness (0.3–1.0mm), roll station count (12–20 stations typical), motor power (4–15kW), and control systems (PLC + touch screen). Additional options cover automatic stacking, inline punching, and IoT-enabled monitoring modules.

Can machines be shipped internationally?

All listed suppliers support global exports with FOB or CIF terms. Sea freight is standard for full-container loads due to machine weight (3–8 tons). Confirm compliance with local voltage and frequency standards at destination ports to avoid installation delays.