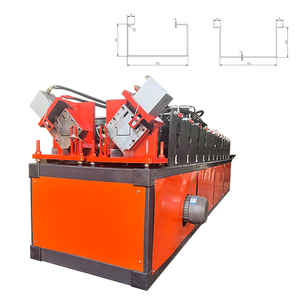

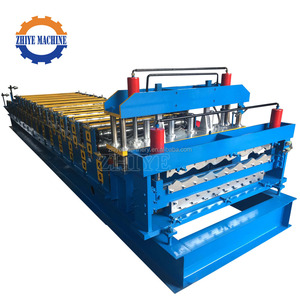

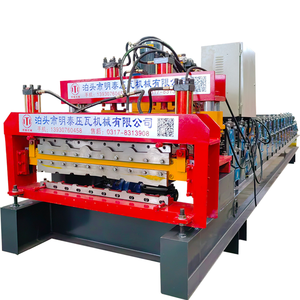

Double Layer Roll Forming Machine Wholesaler

Top sponsor listing

Top sponsor listing

1/9

1/9

CN

CN

1/19

1/19

1/19

1/19

1/28

1/28

1/47

1/47

CN

CN

1/23

1/23

1/25

1/25

1/27

1/27

1/30

1/30

About double layer roll forming machine wholesaler

Where to Find Double Layer Roll Forming Machine Wholesalers?

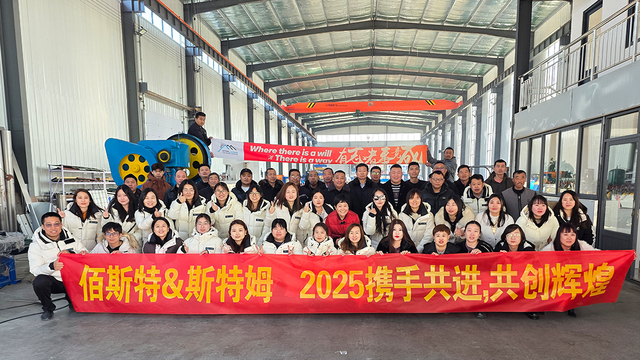

China remains the global epicenter for double layer roll forming machine manufacturing, with key industrial clusters concentrated in Hebei, Tianjin, and Henan provinces. These regions host vertically integrated supply chains that support high-volume production of cold bending machinery, benefiting from proximity to steel suppliers and advanced CNC machining infrastructure. The concentration enables cost efficiencies of 20–35% compared to equivalent equipment produced outside Asia, while mature logistics networks ensure reliable export operations.

Suppliers in these hubs typically operate facilities exceeding 5,000m², integrating decoiling, leveling, roll forming, punching, and cutting systems under one roof. This integration allows seamless production of dual-profile roofing sheets—such as IBR/trapezoidal or corrugated/ribbed combinations—on a single line. Buyers benefit from scalable output, with standard lead times averaging 30–45 days for custom configurations. Regional advantages include access to skilled technical labor, localized component sourcing (e.g., rollers, motors, hydraulic systems), and established export channels serving markets in Southeast Asia, the Middle East, Africa, and South America.

How to Choose Double Layer Roll Forming Machine Wholesalers?

Selecting a reliable supplier requires systematic evaluation across three core dimensions:

Technical Capability & Quality Assurance

Verify compliance with international standards such as ISO 9001 for quality management and CE marking for mechanical safety. While not all suppliers list certifications explicitly, consistent on-time delivery rates above 95% and documented testing procedures indicate operational discipline. Key technical indicators include in-house design teams capable of generating profile drawings, material flow simulations, and PLC control programming. Confirm whether rollers are precision-machined from GCr15 or 40Cr steel and hardened to HRC 58–62 for extended service life.

Production Infrastructure and Scalability

Assess physical capacity through available metrics:

- Minimum factory area of 3,000m² to support full production lines

- In-house engineering teams handling customization (profile design, feed width adjustment, color coding)

- Integration of decoiler, feeder, roll former, punch unit, and cut-off system

- Monthly output capacity exceeding 10 units for bulk procurement readiness

Cross-reference response times (target ≤2 hours) and reorder rates as proxies for customer satisfaction and operational reliability. Suppliers with online revenues exceeding US $500,000 demonstrate consistent transaction volume and market validation.

Customization Flexibility and Transaction Security

Leading wholesalers offer extensive customization: input material thickness (0.3–0.8mm typical), sheet width (up to 1,250mm), motor power (3–7.5kW per station), and output speed (8–20m/min). They also support branding options including logo printing, packaging labels, and user interface localization. For transaction security, prioritize suppliers with verifiable delivery performance and clear dispute resolution mechanisms. Pre-shipment inspections and third-party quality audits are recommended before final payment release.

What Are the Best Double Layer Roll Forming Machine Wholesalers?

| Company Name | Main Products | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Min. Order Price (USD) | Customization Options |

|---|---|---|---|---|---|---|---|

| Shijiazhuang Yingyee Machinery Co., Ltd. | Double-Layer Roof Forming Machines, Trapezoid & Corrugated Roll Formers | US $2,500,000+ | 100% | 100% | ≤2h | $10,000 | Color, thickness, profile, material size, logo, packaging, drawing |

| HAIXING (TIANJIN) INTELLIGENT EQUIPMENT CO., LTD | Double-Layer Roof Roll Formers, Cable Tray Production Lines | US $630,000+ | 100% | 28% | ≤2h | $13,768 | Feed width, sheet type, design, color, logo, label, parameters |

| Cangzhou Xindingli Cold Bending Machinery Co., Ltd. | IBR Roofing Sheet Makers, Long-Span Double-Layer Roll Formers | US $340,000+ | 93% | 80% | ≤2h | $7,000 | Material, thickness, profile, pattern, feeding width, dimensions |

| Henan Wadjay Machinery Co., Ltd. | Tile Making Machinery, Rebar Processing Equipment | US $370,000+ | 100% | 27% | ≤2h | Not listed | Color, material, size, drawing, logo, packaging, graphic |

| Steelmama Machinery Inc | Steel Frame & Purlin Machines, Roofing Sheet Roll Formers | Data Unavailable | Data Unavailable | Data Unavailable | ≤2h | $73,420.82 | Limited public data |

Performance Analysis

Shijiazhuang Yingyee stands out with a 100% reorder rate and multi-million-dollar annual revenue, indicating strong customer retention and market trust. Its broad customization scope and competitive pricing make it suitable for both standardized and engineered-to-order projects. HAIXING (Tianjin) offers robust technical flexibility and transparent production data, backed by consistent delivery performance. Cangzhou Xindingli provides entry-level pricing starting at $7,000, appealing to budget-conscious buyers, though its 93% on-time delivery rate suggests moderate risk in time-sensitive deployments. Henan Wadjay demonstrates reliability with perfect delivery records but lacks detailed product pricing. Steelmama Machinery lists premium-priced models ($73k+), likely targeting specialized or heavy-duty applications, though limited performance metrics constrain comparative assessment.

FAQs

What is the typical MOQ and lead time for double layer roll forming machines?

The standard minimum order quantity is 1 set, with lead times ranging from 30 to 45 days after design confirmation. Some suppliers offer expedited builds in 20–25 days for pre-configured models.

Do suppliers provide customization for different roof profiles?

Yes, most wholesalers support dual-profile configurations such as IBR + trapezoidal or corrugated + ribbed designs. Custom roller sets can be manufactured based on provided CAD drawings or sample sheets.

Are CE or ISO certifications standard among suppliers?

While not universally declared, reputable suppliers adhere to ISO 9001 quality systems and provide CE-compliant electrical panels and mechanical components. Buyers should request certification documentation prior to purchase.

Can I request a machine test or factory audit?

Yes, many suppliers allow remote video inspections during assembly and functional testing. On-site audits are possible by appointment, particularly for large-scale procurement. Some offer trial runs with client-provided materials.

What payment terms and shipping methods are available?

Common payment terms include T/T (30% deposit, 70% before shipment) or L/C at sight. Machinery is typically shipped FOB from ports in Tianjin, Qingdao, or Shanghai, with containerized sea freight being the most economical option for international delivery.