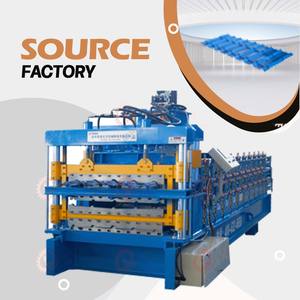

Double Layer Forming Machine Factory

1/41

1/41

1/3

1/3

1/14

1/14

1/9

1/9

1/30

1/30

1/17

1/17

1/10

1/10

1/19

1/19

1/28

1/28

1/34

1/34

1/19

1/19

1/20

1/20

1/3

1/3

About double layer forming machine factory

Where to Find Double Layer Forming Machine Suppliers?

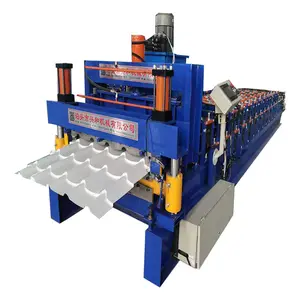

China remains the global epicenter for double layer roll forming machine manufacturing, with key industrial clusters concentrated in Hebei and Shandong provinces. These regions host vertically integrated facilities specializing in cold roll forming technology, supported by mature supply chains for steel processing, hydraulic systems, and automation components. The proximity of raw material suppliers, decoilers, and CNC machining centers within 50km enables streamlined production and rapid prototyping.

Manufacturers in Cangzhou and Botou (Hebei) dominate mid-range production, offering competitive pricing due to localized access to galvanized steel coils and standardized component inventories. Facilities typically operate dedicated production lines for dual-profile roofing and wall panel machines, capable of switching between TR4, IBR, trapezoidal, and glazed tile profiles. Average lead times range from 20–35 days for standard configurations, with some suppliers maintaining pre-assembled units for expedited delivery. Economies of scale reduce unit costs by 18–25% compared to non-specialized producers, particularly for orders exceeding five sets.

How to Choose Double Layer Forming Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Production & Engineering Capability

Verify that suppliers maintain in-house design and assembly capabilities. Key indicators include dedicated R&D teams, custom PLC control programming, and integration of servo-driven hydraulic systems. Prioritize manufacturers with documented experience in producing machines capable of handling material thicknesses from 0.3mm to 1.5mm and coil widths up to 1,250mm. Cross-reference product listings with facility size—suppliers operating under 3,000m² may lack capacity for large-volume orders.

Quality Assurance and Compliance

Confirm adherence to international quality standards. While ISO 9001 certification is not universally listed, on-time delivery rates above 97% serve as a proxy for process discipline. For export markets requiring regulatory compliance, request CE declarations or test reports validating electrical safety (IEC 60204-1) and mechanical stability. Evaluate build quality through available product videos, focusing on frame rigidity, roller alignment, and motor mounting precision.

Customization and After-Sales Support

Assess customization depth: leading suppliers offer adjustments in color coding, profile length, motor power (3–15kW), and control interface languages. Confirm availability of technical documentation in English and post-installation support, including remote troubleshooting and spare parts provisioning. Response times under 2 hours correlate with higher service reliability, especially during commissioning phases.

Transaction Security and Verification

Utilize verified revenue metrics and reorder rates as trust signals. Suppliers with online transaction histories exceeding US $400,000 and reorder rates above 20% demonstrate market acceptance. Implement payment safeguards such as escrow or milestone-based disbursements tied to production milestones. Request sample units for performance validation, particularly for high-speed models (>40 meters/minute), to assess dimensional accuracy and surface finish consistency.

What Are the Best Double Layer Forming Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Hebei Forward Construction Machinery Co., Ltd. | Hebei, CN | Double-layer hydraulic roll formers | US $20,000+ | 100% | ≤2h | - | Color, thickness, motor power, profile length, logo | $5,500 – $25,000 |

| Cangzhou Xinjiujun Machinery Equipment Manufacturing Co., Ltd. | Hebei, CN | Drywall CU/DU/WU, roofing sheet formers | US $20,000+ | 100% | ≤2h | <15% | Color, material size, logo, packaging | $5,000 – $7,200 |

| Botou Shitong Cold Roll Forming Machinery Manufacturing Co., Ltd. | Hebei, CN | Tile making, steel frame, board machinery | US $20,000+ | 100% | ≤4h | - | Limited customization | $11,000 – $16,000 |

| Cangzhou Zhongtuo International Trade Co., Ltd. | Hebei, CN | Full-automatic double-line C/U, trapezoidal | US $4,700,000+ | 100% | ≤2h | 37% | Color, material size, logo, graphic design | $7,500 – $21,900 |

| Jinan Steelmama International Trade Co., Ltd. | Shandong, CN | IBR, trapezoidal, glazed tile formers | US $400,000+ | 100% | ≤2h | 22% | Color, size, logo, packaging, profile design | $12,800 – $28,000 |

Performance Analysis

Cangzhou Zhongtuo stands out with the highest recorded online revenue (US $4.7M+) and a 37% reorder rate, indicating strong customer retention and export volume. Jinan Steelmama offers premium-tier equipment with prices extending to $28,000, targeting high-productivity applications in Latin America and Eastern Europe. Hebei Forward provides the widest price spectrum, including a top-end $25,000 hydraulic model suitable for heavy-gauge metal forming. Suppliers like Cangzhou Xinjiujun compete on entry-level pricing ($5,000–$7,200), ideal for small workshops seeking cost-effective solutions. All top performers maintain 100% on-time delivery, underscoring operational reliability across the segment.

FAQs

What materials can double layer forming machines process?

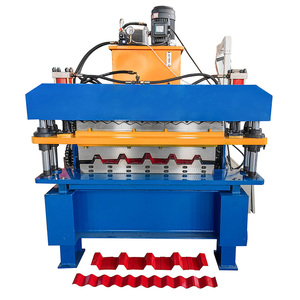

These machines are designed for cold-formed steel coils, including galvanized, aluzinc, and pre-painted steel with thicknesses ranging from 0.3mm to 1.5mm. Some high-end models accommodate stainless steel grades within thinner gauges (≤0.8mm).

What is the typical MOQ and lead time?

Minimum order quantity is typically 1 set. Lead times vary from 20 to 35 days depending on customization level and factory workload. Expedited builds may be available for standard models with pre-stocked components.

Can suppliers customize machine specifications?

Yes, most suppliers offer customization in profile type (e.g., TR4, IBR, corrugated), roll station count (12–20 stations), motor power, control system (PLC brands), and output speed (20–40 m/min). Custom tooling for unique roof models is also available upon technical submission.

Do manufacturers provide installation and training?

Many suppliers offer remote setup guidance via video calls. On-site installation and operator training are typically available at additional cost, especially for automated or high-speed lines. Ensure service terms are clarified before shipment.

How are machines packaged and shipped internationally?

Machines are securely packed in seaworthy wooden crates or container frames. Export documentation includes packing lists, commercial invoices, and bill of lading. FOB terms are common; CIF arrangements are negotiable for full-container loads. Air freight is feasible for compact models but significantly increases shipping costs.