Furring Channel Roll Forming Machine Factories

Top sponsor listing

Top sponsor listing

1/18

1/18

1/25

1/25

1/3

1/3

1/27

1/27

0

0

1/22

1/22

1/1

1/1

1/14

1/14

CN

CN

1/19

1/19

1/3

1/3

1/17

1/17

1/3

1/3

1/19

1/19

About furring channel roll forming machine factories

Where to Find Furring Channel Roll Forming Machine Suppliers?

China remains the global epicenter for furring channel roll forming machine production, with key manufacturing clusters concentrated in Hebei and Guangdong provinces. Cangzhou in Hebei Province hosts a dense network of specialized machinery manufacturers, leveraging regional steel supply chains and decades of metal forming expertise. This industrial ecosystem enables vertically integrated operations—from coil processing to final assembly—reducing component procurement lead times by up to 40%. Similarly, Foshan in Guangdong offers advanced tooling and mold-making capabilities, supporting high-precision roller station fabrication essential for consistent profile accuracy.

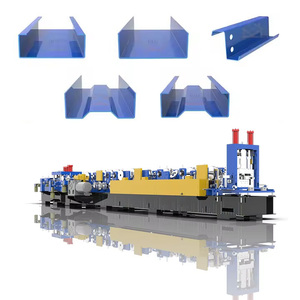

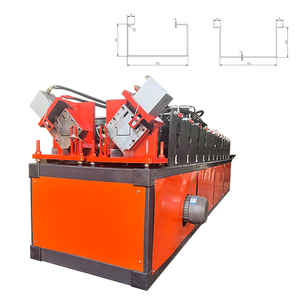

These hubs provide scalable production infrastructure optimized for both standard and custom configurations. Factories typically operate dedicated cold roll forming lines capable of processing galvanized steel coils ranging from 0.4mm to 3.0mm in thickness, with output speeds between 15–50 meters per minute. The proximity of raw material suppliers, CNC machining workshops, and logistics providers within 50km radii ensures efficient order fulfillment. Buyers benefit from shorter lead times (average 30–60 days), 20–30% lower unit costs compared to Western or Southeast Asian alternatives, and flexibility in batch sizing and technical customization.

How to Choose Furring Channel Roll Forming Machine Suppliers?

Selecting reliable suppliers requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international quality standards such as ISO 9001. While not explicitly stated in all supplier profiles, CE marking is critical for market access in Europe and indicates compliance with safety and electromagnetic compatibility directives. Evaluate engineering capacity through availability of PLC-controlled automation, adjustable roller stations, and integration of hydraulic decoilers and stackers. Request design drawings and machine layout plans to verify alignment with your production floor requirements.

Production Infrastructure Assessment

Prioritize suppliers with substantial physical facilities and in-house manufacturing control:

- Minimum factory area exceeding 3,000m² to support full production lines

- In-house R&D or engineering teams capable of modifying roller configurations for C, U, Omega, or Hat profiles

- Integrated processes including slitting, roll forming, punching, and automatic stacking

Cross-reference online revenue indicators and on-time delivery rates (>97% recommended) as proxies for operational stability and order management efficiency.

Transaction Safeguards & After-Sales Support

Utilize secure payment mechanisms such as escrow services that release funds only upon equipment verification at destination. Analyze reorder rates—suppliers with rates above 30% indicate customer satisfaction and product reliability. Confirm post-delivery support including installation guidance, operator training, and spare parts availability. Sample testing is advised to validate dimensional precision, weld integrity, and long-term durability under continuous operation.

What Are the Best Furring Channel Roll Forming Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (Set) | Customization Options |

|---|---|---|---|---|---|---|---|

| Cangzhou Zhongtuo International Trade Co., Ltd. | Tile Making Machinery (870); Steel Frame & Purlin Machines (249) | US $4,700,000+ | 100% | ≤2h | 37% | $8,500–20,000 | Material size, coil width, roller stations, PLC control, packaging, logo |

| Cangzhou Jiuling International Trade Co., Ltd. | Steel Frame & Purlin Machines (Multiple Listings) | Data Unavailable | 100% | ≤1h | No Data | $10,000–15,000 | Color, material size, logo, packaging, graphic labeling |

| Hebei Liming Stamping Form Machine Co., Ltd. | Metal Stud/Track Machines (Multiple) | US $730,000+ | 100% | ≤3h | <15% | $8,500–20,000 | Conveyor, thickness, profile pattern, engineering drawings, machine design |

| Foshan Pusheng Hardware Machinery & Mold Co., Ltd. | Steel Frame & Purlin Machines (149); Board Making Machinery (67) | US $10,000+ | 100% | ≤9h | No Data | $11,500–18,500 | Limited public details; focus on adjustable size systems |

| Xiamen Rollmac Building Technology Co., Ltd. | Omega Furring Channel Machines (Multiple) | US $10,000+ | 100% | ≤2h | 33% | $7,000–13,000 | Color, material size, logo, packaging, graphic labels |

Performance Analysis

Cangzhou-based manufacturers dominate in scale and customization depth. Cangzhou Zhongtuo leads in online transaction volume and product diversity, offering extensive configurability across roller stations, material inputs, and automation levels. Its 37% reorder rate reflects strong buyer retention. Cangzhou Jiuling distinguishes itself with sub-one-hour response times, ideal for time-sensitive procurement cycles. Hebei Liming provides competitively priced machines with robust engineering documentation but exhibits lower repeat purchase activity. Xiamen Rollmac delivers cost-effective entry-level solutions starting below $7,000, targeting budget-conscious buyers seeking basic Omega or C-channel functionality. Foshan Pusheng emphasizes precision hardware and mold integration, suitable for clients requiring tight tolerances in light gauge steel framing.

FAQs

How to verify furring channel roll forming machine supplier reliability?

Validate certifications (ISO 9001, CE) through official registries. Request facility videos or virtual audits to confirm in-house production capabilities. Review transaction history metrics such as on-time delivery rate (target ≥98%) and reorder rate (≥30% preferred). Examine customer feedback focused on machine uptime, ease of maintenance, and technical responsiveness.

What is the typical lead time for furring channel roll forming machines?

Standard configurations require 30–45 days after deposit confirmation. Customized systems with PLC integration, multi-line setups, or special feeding mechanisms may extend to 60 days. Shipping via sea freight adds 20–40 days depending on destination region.

Do suppliers offer customization options?

Yes, most suppliers provide modifications in coil width (typically 100–500mm), material thickness (0.4–3.0mm), roller station count (12–24 stands common), and output speed. Additional features include automatic stacking, hydraulic cutting, digital control panels, and brand-specific labeling. Engineering changes require updated CAD drawings and approval prior to production.

What are common materials processed by these machines?

Primary input is galvanized steel coil (SGCC, SGHC grades), with yield strengths ranging from 230MPa to 550MPa. Some models accommodate pre-painted or aluminum coils. Material thickness typically ranges from 0.4mm to 3.0mm, depending on machine tonnage and roller configuration.

Can furring channel machines produce multiple profiles?

Yes, many modern systems support quick-change roller setups or dual/multi-line configurations allowing production of C, U, Omega, and Hat channels on the same line. Adjustable side guides and programmable cut-off systems enhance versatility for mixed-output environments.