Furring Channel Roll Forming Machine Material

1/3

1/3

CN

CN

1/17

1/17

1/1

1/1

CN

CN

1/3

1/3

CN

CN

0

0

1/19

1/19

CN

CN

1/18

1/18

1/3

1/3

1/13

1/13

1/3

1/3

1/25

1/25

1/3

1/3

1/3

1/3

1/9

1/9

1/14

1/14

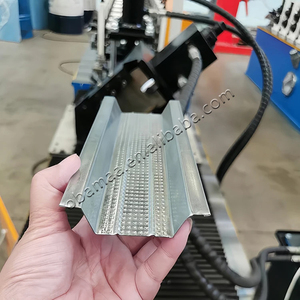

About furring channel roll forming machine material

Where to Find Furring Channel Roll Forming Machine Material Suppliers?

China remains the global epicenter for furring channel roll forming machine production, with key manufacturing clusters concentrated in Guangdong, Fujian, and Hebei provinces. These regions host vertically integrated supply chains that streamline raw material sourcing—primarily galvanized steel coils (SGCC, DX51D), cold-rolled steel, and pre-painted metal sheets—directly feeding into automated roll forming lines. Foshan and Xiamen-based suppliers benefit from proximity to major ports, enabling faster export logistics, while Cangzhou’s industrial base in northern China offers lower labor and operational costs, contributing to a 10–18% cost advantage over coastal counterparts.

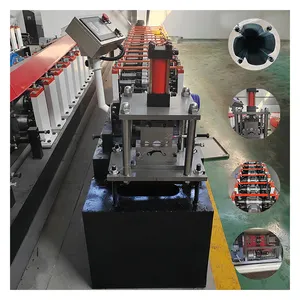

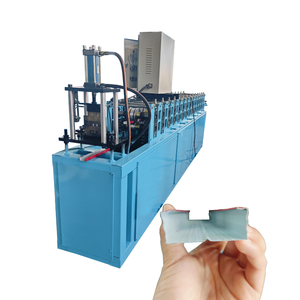

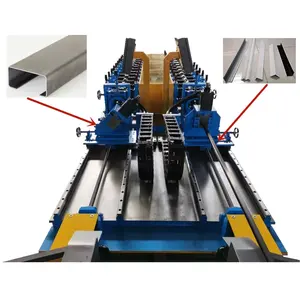

Suppliers in these hubs operate semi-automated to fully automatic production systems capable of processing material thicknesses from 0.4mm to 1.5mm, with output speeds ranging from 8–25 meters per minute. The integration of hydraulic decoilers, levelers, precision rollers, and PLC-controlled cutting units ensures dimensional accuracy within ±0.2mm. Economies of scale are evident in facilities exceeding 5,000m², where component standardization and in-house tooling design reduce changeover times and support rapid prototyping for custom profiles such as hat channels, omega keels, and T-studs.

How to Choose Furring Channel Roll Forming Machine Suppliers?

Procurement decisions should be guided by rigorous supplier evaluation across technical, operational, and transactional criteria:

Material & Engineering Specifications

Confirm compatibility with standard coil materials: SGCC, ASTM A653, or EN 10346-compliant galvanized steel. Machines must support yield strengths up to 550 MPa and include hardened tooling (Cr12 or SKD11 steel) for extended wear resistance. Demand CAD drawings and roll shaft diameter specifications (typically ≥70mm for high-volume operations).

Production Capacity Verification

Assess infrastructure indicators:

- Minimum factory area of 3,000m² for dedicated roll forming machine assembly

- In-house machining capabilities (CNC lathes, milling, heat treatment)

- Presence of R&D teams focused on profile customization and line automation

Cross-reference claimed capacity with verified online revenue (e.g., >US$100,000/year indicates consistent export activity) and on-time delivery performance (>97% recommended).

Quality Assurance & Transaction Security

Prioritize suppliers with ISO 9001-certified quality management systems. CE marking is essential for compliance in European markets. Utilize secure payment mechanisms such as escrow services and request post-shipment inspection rights. Conduct sample testing to validate formed section tolerances, edge curl, and weld seam integrity (where applicable). Video audits of production floors can verify automation levels and inventory management practices.

What Are the Best Furring Channel Roll Forming Machine Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Price Range (USD/set) | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Foshan Pusheng Hardware Machinery & Mold Co., Ltd. | Guangdong, CN | Steel Frame & Purlin Machines, Board Making Machinery | US $10,000+ | 100% | ≤9h | - | $11,500–18,500 | Not specified |

| Xiamen HF Roll Machinery Co., Ltd. | Fujian, CN | Roll Forming Machines (Custom Manufacturer) | US $90,000+ | 100% | ≤9h | 100% | $10,800–45,000 | Yes |

| Steelmama Machinery Inc | Hebei, CN | Tile Making Machinery, Steel Frame & Purlin Machines | - | - | ≤1h | - | $10,900–28,000 | Yes |

| Cangzhou Best Machinery Manufacturing Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Custom Manufacturer | US $150,000+ | 100% | ≤4h | 100% | $8,000–27,000 | Color, material, size, logo, packaging |

| Jinan Steelmama International Trade Co., Ltd. | Shandong, CN | Multispecialty Supplier (Roll Forming Equipment) | US $400,000+ | 100% | ≤2h | 22% | $10,900–28,000 | Color, material, size, logo, packaging |

Performance Analysis

Cangzhou Best Machinery and Xiamen HF Roll stand out with 100% reorder rates and robust online transaction volumes, signaling strong customer satisfaction and export reliability. Jinan Steelmama leads in responsiveness (≤2h) and has the highest reported revenue, indicating scalability and active international engagement. While some suppliers offer entry-level machines below $8,500, these typically serve small-scale or emerging markets and may lack advanced controls or durability for continuous operation. Buyers seeking automation should target vendors offering full-line integration—decoiler, forming, punching, and stacking—with PLC and touchscreen HMI interfaces. Suppliers with declared customization options provide flexibility for regional profile variations, particularly in North and South American construction standards.

FAQs

How to verify furring channel roll forming machine supplier reliability?

Validate certifications through independent registries. Request factory audit reports or video walkthroughs showing live production. Analyze transaction history, focusing on consistent on-time delivery and verifiable customer feedback related to machine uptime and after-sales technical support.

What is the typical lead time for roll forming machines?

Standard configurations require 30–45 days from order confirmation. Customized systems with integrated punching or multi-track capability may take 50–65 days. Air freight shipping adds 5–10 days; sea freight ranges from 15–35 days depending on destination port.

Do suppliers offer material compatibility guarantees?

Reputable manufacturers specify acceptable input material ranges (thickness, width, tensile strength) and often provide test run videos using buyer-specified coil grades. Some include spare roll sets or tooling adjustment guides to accommodate future material changes.

What is the average minimum order quantity (MOQ)?

The standard MOQ is 1 set, allowing buyers to pilot equipment before scaling procurement. Bulk orders (3+ units) often unlock pricing discounts of 5–12% and expedited shipping terms.

Can suppliers assist with installation and training?

Many suppliers offer remote setup support via video call. On-site commissioning and operator training are available, typically at an additional cost ($1,500–$3,000 including travel). Documentation packages usually include electrical schematics, maintenance manuals, and spare parts lists.