Roll Forming Machine Factory

Top sponsor listing

Top sponsor listing

CN

CN

CN

CN

About roll forming machine factory

Where to Find Roll Forming Machine Factory Suppliers?

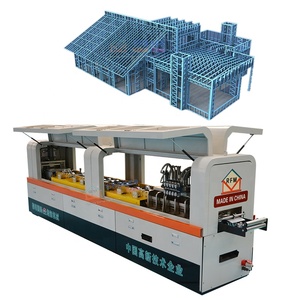

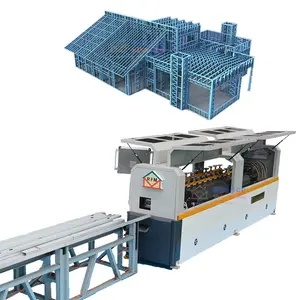

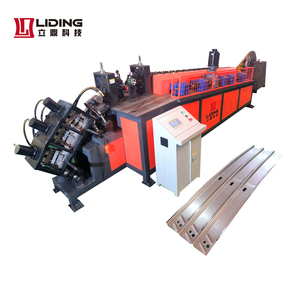

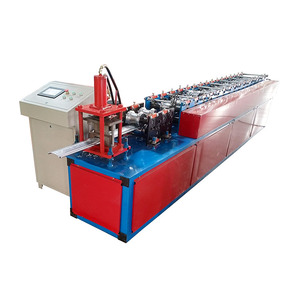

China remains the global epicenter for roll forming machine manufacturing, with key industrial clusters concentrated in Hebei and Henan provinces. These regions host vertically integrated factories specializing in cold roll forming technology for construction, infrastructure, and industrial applications. Hebei, particularly around Botou and Shijiazhuang, accounts for over 40% of China’s roll forming machinery output, supported by proximity to major steel production hubs and efficient rail-sea logistics networks.

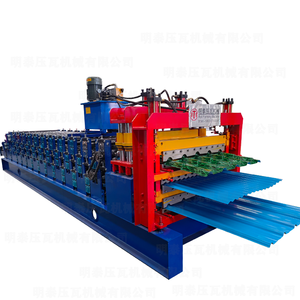

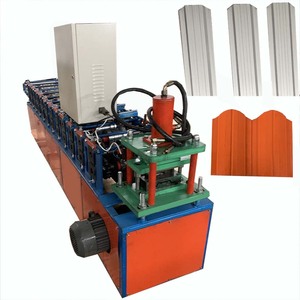

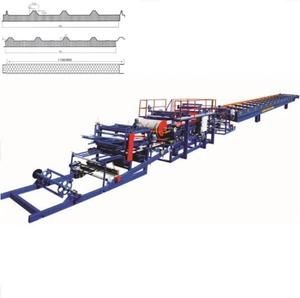

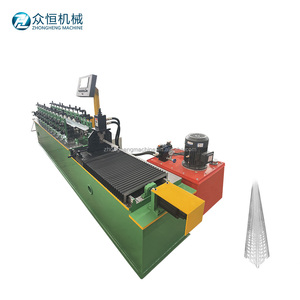

The concentration enables suppliers to maintain tight control over material sourcing, machining, and final assembly—reducing component lead times by up to 25%. Factories typically operate dedicated production lines for tile making, purlin fabrication, panel profiling, and structural shaping machines. This specialization allows for rapid reconfiguration between standard and custom models, with average delivery windows ranging from 30 to 50 days depending on automation level and complexity. Buyers benefit from scalable capacity, localized supply chains, and competitive pricing driven by mature supplier ecosystems.

How to Choose Roll Forming Machine Factory Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Production & Engineering Capability

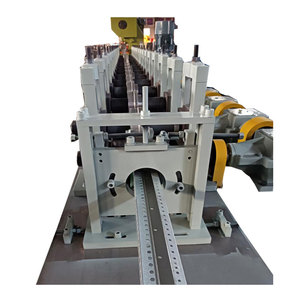

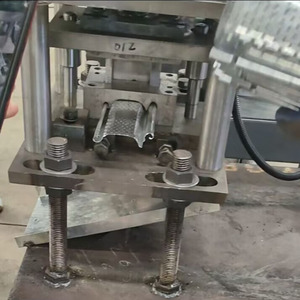

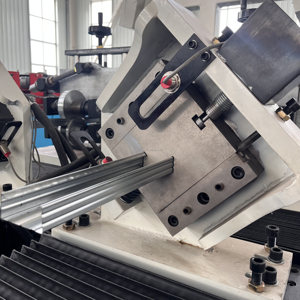

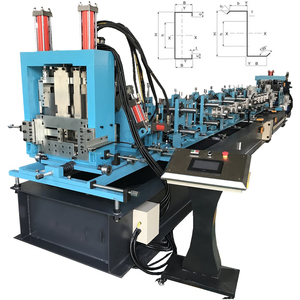

Prioritize manufacturers with in-house design teams and CNC-based fabrication capabilities. Key indicators include dedicated R&D departments, use of SolidWorks/AutoCAD for customization, and integration of PLC-controlled automation systems. Confirm that the factory operates full production lines—from decoiler and leveling systems to roll stations, punching units, and cutoff mechanisms—ensuring end-to-end quality oversight.

Quality Assurance Standards

Verify adherence to international standards such as CE certification for European markets or equivalent safety compliance frameworks. While ISO 9001 is not explicitly stated in available data, consistent on-time delivery rates (100% across all listed suppliers) suggest structured quality management systems. Request documentation on material traceability, weld integrity testing, and post-production calibration procedures.

Customization and Technical Flexibility

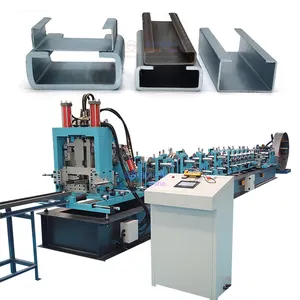

Assess scope of customization: leading suppliers support adjustments in profile geometry, material thickness (typically 0.3–6mm), feeding width, color coding, labeling, and packaging. Advanced vendors offer digital twin simulations or 3D renderings prior to production. Ensure engineering teams can interpret technical drawings and modify tooling rolls for unique cross-sections.

Transaction Reliability Metrics

Evaluate performance using verifiable KPIs:

- On-time delivery rate ≥98%

- Average response time ≤4 hours

- Reorder rate above 30% indicating customer retention

- Transparent online revenue history reflecting consistent export activity

Prefer suppliers offering third-party transaction protection and clear dispute resolution protocols. Conduct video audits of factory floors and assembly lines before order placement to validate claimed capacities.

What Are the Best Roll Forming Machine Factory Suppliers?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Customization Options |

|---|---|---|---|---|---|---|---|---|

| Shijiazhuang Yingyee Machinery Co., Ltd. | Hebei, CN | Steel Frame & Purlin Machines, Sandwich Panel Lines, Cable Tray Formers | US $2,500,000+ | 100% | ≤1h | 100% | 5+ product lines | Material, thickness, pattern, profile, label, design drawing |

| Hebei Liming Stamping Form Machine Co., Ltd. | Hebei, CN | Tile Making Machinery, Coil Slitting Lines, Pipe Making Equipment | US $530,000+ | 100% | ≤3h | <15% | 12+ products | Color, material, size, logo, packaging, graphic |

| Zhengzhou Hokang Machinery Co., Ltd. | Henan, CN | Rack Beam Machines, Roof Sheet Formers, Shutter Door Slat Lines | US $280,000+ | 100% | ≤1h | 30% | 5+ models | Profile, mold, bending, color, thickness, design drawing |

| Botou Mingtai Roll Forming Machinery Co., Ltd. | Hebei, CN | Glazed Tile, Ceiling Panel, Triple-Layer Roll Formers | US $70,000+ | 100% | ≤5h | - | 5+ active listings | Limited customization per tags |

| Botou Shibo Machinery Manufacturing Co., Ltd. | Hebei, CN | Sandwich Panel, Standing Seam Roof, Wall Batten Machines | - | 100% | ≤4h | - | 5+ product types | Factory customization noted |

Performance Analysis

Shijiazhuang Yingyee stands out with a 100% reorder rate and sub-one-hour response time, indicating strong client satisfaction and operational responsiveness. The company supports high-value automated lines priced up to $170,000, reflecting advanced engineering capability. Hebei Liming offers broadest product diversity but has a low reorder rate (<15%), suggesting potential gaps in after-sales service or long-term reliability. Zhengzhou Hokang combines fast response times with moderate reorder performance (30%) and cost-effective entry-level models starting below $4,000. Botou-based suppliers dominate niche roofing and cladding segments, while Henan-based producers focus on modular, mid-range solutions suitable for small to medium workshops.

FAQs

How to verify roll forming machine factory reliability?

Cross-check declared certifications (CE, ISO) with official registries. Request facility videos showing active production lines, CNC machining centers, and finished goods testing. Analyze transaction history including verified revenue, repeat buyer metrics, and customer reviews focused on durability and commissioning support.

What is the typical minimum order quantity (MOQ)?

All listed suppliers specify an MOQ of 1 set, allowing buyers to procure single units for testing or small-scale deployment. Bulk orders often unlock price discounts and extended warranty terms.

What are common lead times for roll forming machines?

Standard models typically ship within 30–45 days after deposit confirmation. Customized systems with specialized tooling or automation integrations may require 50–70 days. Expedited builds are possible with premium fees.

Do suppliers support international shipping and installation?

Yes, experienced exporters provide turnkey logistics under FOB or CIF terms. Many offer remote commissioning via video guidance; on-site technician dispatch may incur additional charges. Confirm inclusion of manuals, spare parts kits, and electrical compatibility (voltage/frequency).

How extensive is customization for roll forming machines?

Leading suppliers enable full customization of roll profiles, material feed width, punch patterns, cutting length, and control systems. Clients can submit DXF/CAD files for profile replication. Additional options include color-coded frames, brand labeling, and tailored packaging for export compliance.