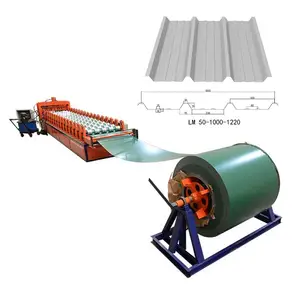

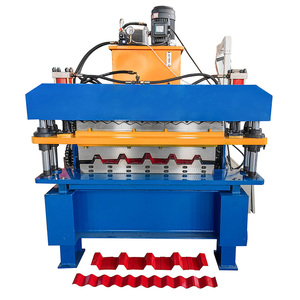

Double Layer Roofing Sheet Roll Forming Machine Factories

Top sponsor listing

Top sponsor listing

1/23

1/23

1/19

1/19

1/13

1/13

1/47

1/47

1/20

1/20

1/25

1/25

1/28

1/28

1/19

1/19

1/11

1/11

1/11

1/11

1/9

1/9

CN

CN

1/17

1/17

1/35

1/35

1/22

1/22

CN

CN

1/18

1/18

1/27

1/27

About double layer roofing sheet roll forming machine factories

Where to Find Double Layer Roofing Sheet Roll Forming Machine Suppliers?

China remains the global epicenter for double layer roofing sheet roll forming machine production, with key manufacturing clusters concentrated in Hebei and Tianjin. These regions host vertically integrated facilities specializing in cold bending technology and automated panel fabrication. The proximity to major steel mills in Tangshan enables efficient access to raw materials such as galvanized iron (GI), pre-painted galvanized iron (PPGI), and color-coated coils—critical inputs that reduce material procurement lead times by up to 25%.

Industrial zones in Cangzhou and Hebei feature mature ecosystems where suppliers operate full production lines—from coil unwinding and leveling to roll forming, punching, cutting, and final stacking. This integration supports rapid prototyping and scalable output, with leading factories capable of producing 1–5 machines per month depending on complexity. Buyers benefit from localized supply chains offering 20–30% cost advantages over European or North American manufacturers, alongside shorter lead times averaging 30–45 days for standard configurations.

How to Choose Double Layer Roofing Sheet Roll Forming Machine Suppliers?

Selecting a reliable supplier requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Design Capability

Confirm adherence to international quality standards such as ISO 9001. While not all suppliers list CE certification explicitly, verify compliance through engineering documentation, especially for electrical components and safety guards. Evaluate design flexibility: advanced suppliers offer customization in feed width (typically 800–1,250mm), roller count (12–24 rows), motor power (3–11kW), and discharge length (6–12 meters). Request CAD drawings and control system specifications (PLC brands like Delta or Siemens) prior to order placement.

Production Infrastructure Assessment

Prioritize suppliers with dedicated R&D teams and in-house machining capabilities for rollers and frames. Key indicators include:

- Minimum factory area exceeding 3,000m² to support assembly and testing

- In-house CNC machining and welding units ensuring precision alignment

- Capacity to produce multi-layer configurations (double/triple layer) with interchangeable molds

Cross-reference facility scale with on-time delivery performance—target suppliers maintaining ≥95% fulfillment rates.

Transaction Security & After-Sales Support

Utilize secure payment mechanisms such as escrow services until equipment passes destination inspection. Assess after-sales readiness by requesting training protocols, spare parts availability, and remote troubleshooting support via video guidance. Analyze reorder rates as a proxy for customer satisfaction; suppliers with rates above 50% typically provide robust service infrastructure.

What Are the Best Double Layer Roofing Sheet Roll Forming Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Main Product Range |

|---|---|---|---|---|---|---|---|---|

| Hebei Liming Stamping Form Machine Co., Ltd. | Hebei, CN | Multispecialty Supplier | US $730,000+ | 100% | ≤3h | <15% | Color, material, size, logo, packaging, graphic | Tile Making Machinery, Steel Frame & Purlin Machines, Coil Slitting Line |

| Tangshan Shuoen International Trade Co., Ltd. | Tangshan, CN | Multispecialty Supplier | US $4,200,000+ | 100% | ≤2h | 33% | Layer type, thickness, profile, motor power, coil width, electrical components | Double-layer, three-layer, trapezoidal, corrugated tile machines |

| Cangzhou Huanuo Cold Bending Machine Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $820,000+ | 100% | ≤3h | 16% | Sheet thickness, width, length, roller count, mold design, triple layer option | Hydraulic automatic double-layer panels, slitting lines |

| Tianjin Haixing Imp & Exp Co., Ltd. | Tianjin, CN | Custom Manufacturer | US $1,100,000+ | 100% | ≤1h | 63% | Profile, color, thickness, length, packaging, material grade | Precision roll formers, trapezoidal and corrugated roofing systems |

| Cangzhou Forward Roll Forming Machinery Manufacturing Co., Ltd. | Cangzhou, CN | Custom Manufacturer | US $990,000+ | 92% | ≤2h | 100% | Double-layer configuration, feeding width, hydraulic platform, gearbox, profile design | High-capacity double-layer roofing machines, CZ purlin lines |

Performance Analysis

Tangshan Shuoen leads in transaction volume with over US $4.2 million in online revenue, indicating strong market penetration and export capability. Tianjin Haixing stands out for customer retention, achieving a 63% reorder rate—among the highest in the segment—supported by sub-1-hour response times and consistent delivery performance. Cangzhou Forward demonstrates exceptional loyalty metrics with a 100% reorder rate, suggesting high satisfaction despite a slightly lower on-time delivery score (92%). Hebei Liming and Cangzhou Huanuo offer competitive entry-level pricing but exhibit lower repeat purchase behavior, potentially reflecting differences in post-sale support or niche targeting.

FAQs

How to verify double layer roofing sheet machine supplier reliability?

Validate technical credentials through ISO 9001 certification and request test reports for critical subsystems (e.g., PLC controls, hydraulic stations). Conduct virtual audits to confirm in-house production capabilities. Review transaction history focusing on dispute resolution outcomes and buyer feedback related to machine durability and setup assistance.

What is the typical MOQ and lead time?

Most suppliers set minimum order quantity at 1 set. Customized models may require longer lead times of 40–55 days, while standard double layer machines ship within 30–40 days. Some suppliers accept trial orders for single units, particularly when bundled with container shipments of complementary machinery.

Do suppliers offer customization options?

Yes, all listed manufacturers provide extensive customization including roller profiles (IBR, trapezoidal, wave-shaped), material compatibility (GI, PPGI, aluminum), feed width (up to 1,250mm), and automation level (manual vs. fully automatic with PLC control). Clients can also specify color schemes, branding labels, and packaging configurations.

Can these machines process multiple roof panel types?

Advanced models support dual-profile production using interchangeable rollers. Some suppliers offer T-shaped or three-layer configurations enabling simultaneous output of different sheet designs. Confirm tooling changeover procedures and downtime implications before procurement.

What are common payment and logistics terms?

Standard payment terms include 30% advance T/T with balance before shipment. FOB terms are prevalent, though some suppliers offer CIF arrangements to major global ports. Sea freight is standard for full-container loads; air freight is feasible only for compact or modular units due to weight and dimension constraints.