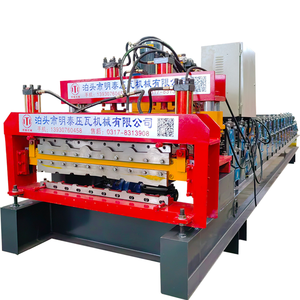

Double Layer Roll Forming Machine Exporter

1/27

1/27

1/3

1/3

1/13

1/13

1/3

1/3

1/3

1/3

1/3

1/3

1/25

1/25

1/25

1/25

1/3

1/3

1/2

1/2

1/25

1/25

1/9

1/9

1/11

1/11

1/9

1/9

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/2

1/2

About double layer roll forming machine exporter

Where to Find Double Layer Roll Forming Machine Exporters?

China remains the global epicenter for double layer roll forming machine manufacturing, with key industrial hubs concentrated in Hebei, Henan, and Shandong provinces. These regions host vertically integrated production ecosystems that combine precision engineering, steel processing, and automation expertise. Suppliers in Botou (Hebei) specialize in compact, high-efficiency models targeting emerging markets, while manufacturers in Zhengzhou (Henan) focus on fully automatic systems with advanced PLC controls and multi-profile capabilities.

The clustering of component suppliers—ranging from gearboxes to hydraulic units—within 50km radii enables rapid assembly and reduces lead times by up to 30% compared to decentralized production models. Average delivery windows range from 25–40 days for standard configurations, with localized supply chains contributing to a 15–25% cost advantage over European or North American producers. Export-oriented facilities are equipped with modular design frameworks, allowing seamless integration of voltage, language, and safety adaptations for international compliance.

How to Choose Double Layer Roll Forming Machine Exporters?

Procurement decisions should be guided by structured evaluation criteria focused on technical reliability, operational transparency, and transactional security:

Technical & Quality Compliance

Confirm adherence to ISO 9001 quality management standards as a baseline requirement. For operations in regulated markets, CE certification is essential for customs clearance and equipment safety validation. Request documentation covering material traceability (e.g., Q235B/Q355B steel specifications), welding integrity tests, and electrical system compliance (IEC 60204-1). Verify control systems utilize reputable brands such as Delta or Siemens PLCs with HMI interfaces.

Production Capacity Assessment

Evaluate supplier infrastructure through objective indicators:

- Minimum factory area exceeding 3,000m² to support dedicated roll forming, welding, and testing zones

- In-house machining capabilities including CNC lathes, plasma cutters, and roller hardening treatments

- Dedicated R&D teams enabling customization of roll profiles, feeding widths (760–1050mm), and output speeds (up to 15m/min)

- Cross-reference online revenue data and reorder rates as proxies for market acceptance and after-sales performance

Transaction Risk Mitigation

Utilize secure payment mechanisms such as letter of credit or platform-based escrow until post-delivery inspection is completed. Prioritize suppliers with documented on-time delivery records (≥98%) and sub-4-hour average response times. Conduct virtual audits via video walkthroughs to validate production lines and inventory levels before order confirmation.

What Are the Leading Double Layer Roll Forming Machine Exporters?

| Company Name | Location | Verification Status | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| Tianjin Haixing Imp & Exp Co., Ltd. | Tianjin, CN | Custom Manufacturer | US $1,100,000+ | 100.0% | ≤1h | 63% | Color, thickness, profile, length, logo, design | $6,000–19,800 |

| Henan Randro Machinery Equipment Co., Ltd. | Zhengzhou, CN | — | US $350,000+ | 100.0% | ≤2h | 57% | Limited (standard tile/metal profiles) | $5,300–8,800 |

| Jinan Steelmama International Trade Co., Ltd. | Jinan, CN | Multispecialty Supplier | US $400,000+ | 100.0% | ≤2h | 22% | Color, size, logo, packaging, graphic | $11,550–18,800 |

| Botou Junsheng Roll Forming Machine Equipment Co., Ltd. | Botou, CN | — | Not disclosed | 100.0% | ≤2h | Not available | Basic model variants only | $6,400–6,800 |

| Botou Xinbo Import And Export Trade Co., Ltd. | Botou, CN | — | US $10,000+ | 100.0% | ≤4h | <15% | Standard configurations with limited flexibility | $11,000–17,500 |

Performance Analysis

Tianjin Haixing stands out with the highest reorder rate (63%) and broadest customization scope, indicating strong customer retention and engineering adaptability. Henan Randro offers the most competitive pricing, with entry-level models starting below $5,500, making it suitable for budget-conscious buyers seeking reliable semi-automatic systems. Jinan Steelmama provides mid-to-high-end solutions with comprehensive branding and packaging options ideal for distributors. Botou-based exporters emphasize affordability and fast throughput but offer minimal design flexibility. All top-tier suppliers maintain perfect on-time delivery records, though response efficiency varies significantly—from under one hour to over four hours.

FAQs

What certifications should double layer roll forming machine exporters have?

Essential certifications include ISO 9001 for quality management and CE marking for compliance with EU machinery directives. Buyers in North America should confirm adherence to ANSI and OSHA safety standards. Request test reports for electrical panels, mechanical guards, and emergency stop systems.

What is the typical minimum order quantity (MOQ)?

Most exporters set MOQ at 1 set or 1 piece, facilitating low-volume trial orders. Bulk pricing typically applies at 3+ units, offering 5–12% discounts depending on configuration complexity and shipping terms.

How long does customization take?

Custom profile development requires 10–20 days for tooling fabrication and machine calibration. Full automation integration (e.g., decoiler, punching unit, stacking system) may extend lead time by an additional 15 days. Suppliers provide CAD drawings within 48–72 hours upon receipt of technical specifications.

Can suppliers handle international shipping?

Yes, experienced exporters manage FOB, CIF, and DAP shipping arrangements. They coordinate container loading, marine insurance, and destination port formalities. Sea freight is standard for full-machine shipments due to dimensional constraints and weight (typically 4–8 tons per unit).

Do exporters offer installation and training support?

Many provide remote setup guidance via video call. On-site commissioning services are available at additional cost, typically billed at $150–200/day plus travel expenses. Documentation includes multilingual operation manuals and maintenance checklists.