Shutter Roll Forming Machine Exporter

Top sponsor listing

Top sponsor listing

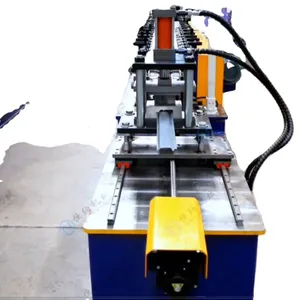

About shutter roll forming machine exporter

Where to Find Shutter Roll Forming Machine Exporters?

China remains the dominant hub for shutter roll forming machine manufacturing, with key industrial clusters concentrated in Hebei and Shanghai. The Cangzhou region in Hebei Province hosts a dense network of specialized metal forming machinery producers, leveraging proximity to raw material suppliers and major ports like Tianjin. This strategic location reduces logistics costs by 10–15% compared to inland regions. Shanghai-based manufacturers benefit from advanced R&D infrastructure and export-ready compliance frameworks, catering to international markets with stringent technical and regulatory requirements.

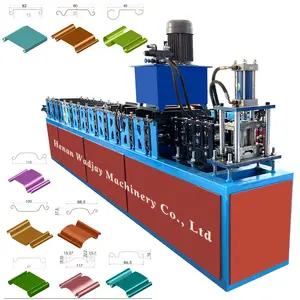

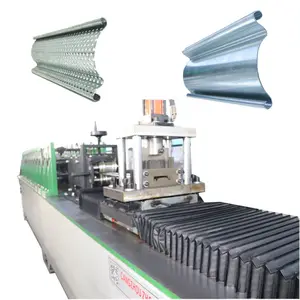

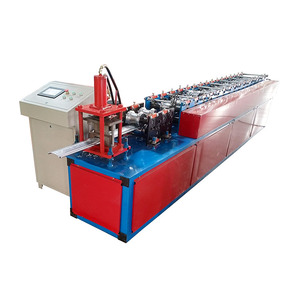

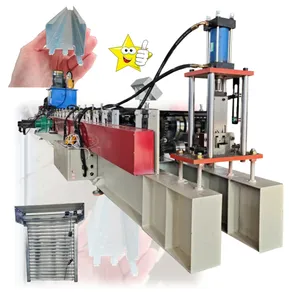

These clusters feature vertically integrated production ecosystems where design, fabrication, assembly, and testing occur under one operational umbrella. Suppliers typically maintain in-house capabilities for CNC machining, laser cutting, hydraulic system integration, and PLC-controlled automation. This integration enables rapid prototyping, consistent quality control, and scalability for both standard and custom configurations. Buyers can expect lead times of 25–40 days for standard machines, with localized supply chains supporting MOQs as low as one set for select models.

How to Choose Shutter Roll Forming Machine Exporters?

Selecting reliable exporters requires systematic evaluation across three critical dimensions:

Technical Compliance & Certification

Verify adherence to internationally recognized standards such as ISO 9001 for quality management. For exports to Europe or North America, confirm CE marking and compliance with machinery safety directives (e.g., EU 2006/42/EC). Request documentation on electrical system certifications, motor specifications, and structural load testing—particularly for high-speed or heavy-duty models designed for commercial roller shutter production.

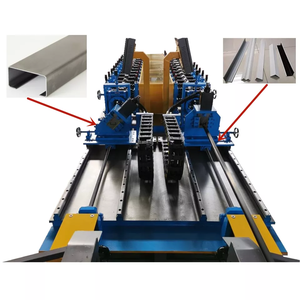

Production Capacity & Customization Capability

Assess supplier infrastructure through verifiable metrics:

- Facility size exceeding 3,000m² indicating scalable operations

- In-house engineering teams capable of customizing frame profiles, louver designs, and drive mechanisms

- Integration of precision tooling, servo controls, and automated packaging systems

Cross-reference online revenue indicators and order fulfillment rates to validate operational stability. Prioritize suppliers offering customization options in material thickness (0.6–2.0mm range), profile width (75–120mm common), and motor integration (hidden vs. external).

Transaction Reliability & After-Sales Support

Analyze performance indicators such as on-time delivery rate (target ≥96%), response time (ideally ≤4 hours), and reorder rate as proxies for customer satisfaction. Confirm availability of remote technical support, installation guides, and spare parts supply chains. For high-value procurement, utilize secure payment structures with milestone-based disbursements tied to production progress and pre-shipment inspections.

What Are the Leading Shutter Roll Forming Machine Exporters?

| Company Name | Location | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Verified Status |

|---|---|---|---|---|---|---|---|---|

| Cangzhou Zhongheng Machine Manufacture Co.,ltd. | Cangzhou, CN | Roll Forming Machines, Tile Making Machinery, Steel Frame Equipment | US $410,000+ | 100% | ≤4h | 100% | Yes | Not specified |

| Cangzhou Hener Machinery Co.,Ltd. | Cangzhou, CN | Roller Shutter Door Machines, Strip Forming Lines | US $340,000+ | 100% | ≤2h | 42% | Yes | Custom Manufacturer |

| CANGZHOU HAUAN ROLL FORMING MACHINERY CO., LTD. | Cangzhou, CN | Roller Shutter Door Machines, Frame Forming Equipment | US $220,000+ | 83% | ≤1h | 55% | Yes | Custom Manufacturer |

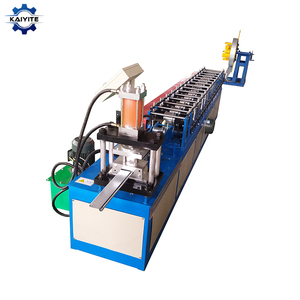

| Botou Kaiyite Cold Bending Machinery Co., Ltd. | Botou, CN | Rolling Shutter Production Lines, Metal Curtain Machines | US $150,000+ | 100% | ≤3h | 16% | Yes | Custom Manufacturer |

| Shanghai Toma Building Material Co., Ltd. | Shanghai, CN | Roll Forming Machines, Windows, Sliding Doors, Pergolas | US $140,000+ | 96% | ≤3h | <15% | Yes | Custom Manufacturer |

Performance Analysis

Cangzhou Zhongheng stands out with a perfect 100% on-time delivery and reorder rate, indicating strong production discipline and customer retention. Cangzhou Hener follows closely with full delivery compliance and robust customization depth, including alloy steel selection, double-layer profiles, and CNC-machined rollers. While CANGZHOU HAUAN offers the fastest average response time (≤1h), its lower on-time delivery rate suggests potential bottlenecks in fulfillment consistency. Shanghai Toma, though diversified into building materials, maintains reliable logistics performance but exhibits limited repeat business, possibly due to broader market positioning rather than niche specialization. Buyers seeking high-volume reliability should prioritize suppliers with verified manufacturing status, 100% delivery records, and comprehensive technical documentation.

FAQs

How to verify shutter roll forming machine exporter credibility?

Request copies of ISO 9001 and CE certificates, validated through issuing bodies. Conduct virtual factory audits to observe CNC machining centers, assembly lines, and quality inspection stations. Review transaction history indicators such as confirmed orders, buyer feedback, and dispute resolution outcomes.

What is the typical minimum order quantity?

Most exporters accept MOQs of 1 set for standard models. Customized or turnkey production lines may require higher commitments depending on complexity. Some suppliers offer sample units at 10–15% above base pricing for validation purposes.

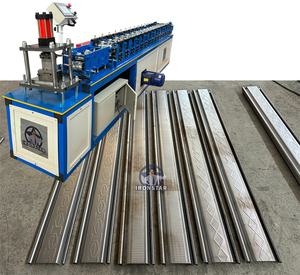

Can suppliers customize machine specifications?

Yes, leading exporters support customization of louver profile geometry, material feed thickness (typically 0.8–1.5mm), motor type (tube or external), and control systems (manual, semi-automatic, or fully PLC-integrated). Design modifications require CAD drawings or sample references for feasibility assessment.

What are common lead times for shipment?

Standard machines ship within 25–35 days after order confirmation. Custom configurations may extend lead times to 45 days. Sea freight transit to Europe or North America averages 25–35 days, with FOB terms commonly offered and CIF available upon request.

Do exporters provide technical support post-purchase?

Reputable suppliers offer remote troubleshooting via video guidance, English-language operation manuals, and spare parts provisioning. Some provide optional on-site commissioning services at additional cost. Confirm support duration and response windows before finalizing contracts.