Calculating Mean

1/3

1/3

1/3

1/3

CN

CN

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/30

1/30

1/3

1/3

1/8

1/8

1/1

1/1

0

0

1/3

1/3

1/11

1/11

0

0

1/3

1/3

1/3

1/3

1/3

1/3

1/7

1/7

About calculating mean

Where to Find Calculating Mean Suppliers?

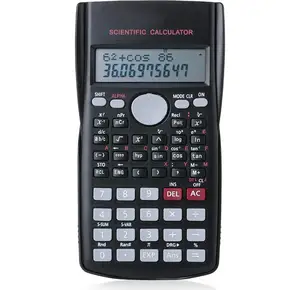

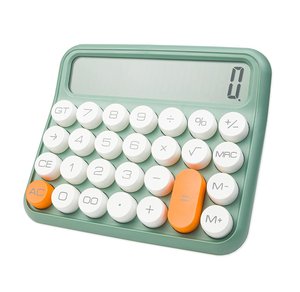

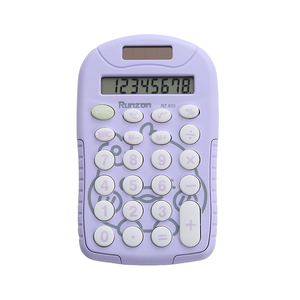

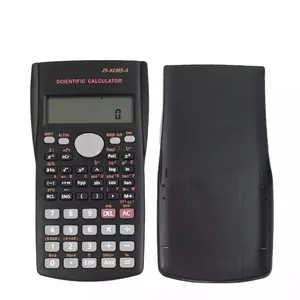

No dedicated suppliers specializing in "calculating mean" as a physical product were identified in the current industrial supplier databases. The term "calculating mean" refers to a statistical computation rather than a manufactured good, commonly implemented through software algorithms, data processing systems, or integrated into analytical instruments such as scientific calculators, laboratory equipment, or industrial control systems.

Manufacturers producing devices capable of performing mean calculations—such as electronic measuring instruments, data loggers, or process controllers—are primarily concentrated in technology and electronics hubs in China, including Shenzhen (Guangdong Province), Suzhou (Jiangsu), and Shanghai. These regions host advanced electronics manufacturing clusters with access to PCB assembly lines, firmware development teams, and precision testing facilities. Integrated supply chains enable rapid prototyping and scalable production of embedded computational functions within hardware platforms.

Buyers seeking hardware solutions with built-in mean calculation functionality should target suppliers of industrial instrumentation, test & measurement equipment, or OEM electronics manufacturers. These ecosystems support customization of mathematical functions within firmware, enabling real-time data averaging for applications in quality control, environmental monitoring, and process automation.

How to Choose Suppliers for Devices with Mean Calculation Capability?

When sourcing hardware that performs mean calculations, evaluate suppliers based on the following technical and operational criteria:

Functional Specification Compliance

Confirm that the device firmware or software includes arithmetic mean, weighted mean, or moving average functions as required. Request demonstration units or code-level verification for custom programming. For regulated environments (e.g., medical, aerospace), ensure compliance with relevant standards such as IEC 62304 (medical software) or ISO/IEC 17025 (testing laboratories).

Production and Engineering Capacity

Assess supplier capabilities in embedded system development and electronic manufacturing:

- Minimum 2,000m² production facility with SMT and THT assembly lines

- In-house software/firmware development team (minimum 5 engineers)

- Access to calibration labs and statistical validation tools

Verify integration of mathematical functions through sample output logs under variable input conditions.

Quality Management Systems

Prioritize suppliers with ISO 9001 certification for consistent production quality. For high-precision applications, validate adherence to ISO/IEC 17025 for measurement traceability. Review internal testing protocols for algorithm accuracy, particularly rounding error handling and floating-point precision.

Transaction and Technical Safeguards

Utilize escrow-based payment terms until functional acceptance of samples. Require source code documentation or API access for validation if customization is involved. Conduct factory audits via video tour to confirm R&D infrastructure and testing workflows. Benchmark calculation speed and accuracy against known datasets prior to volume ordering.

What Are the Best Suppliers for Computational Devices Including Mean Calculation?

Due to the absence of suppliers explicitly offering “calculating mean” as a standalone product, no comparative supplier table can be generated from available data. However, procurement professionals should focus on established manufacturers of digital multimeters, data acquisition systems, programmable logic controllers (PLCs), and scientific calculators when integrating mean computation into operational workflows.

Performance Analysis

Leading electronics OEMs in Guangdong and Jiangsu provinces demonstrate strong capabilities in embedding statistical functions within microcontroller-based devices. Companies with dedicated firmware teams are better positioned to customize mean calculation parameters, such as sample window size, outlier filtering, or real-time display updates. Buyers should prioritize partners with documented experience in mathematical function implementation and third-party verified measurement accuracy.

FAQs

Can suppliers customize mean calculation algorithms in hardware?

Yes, many electronics manufacturers offer firmware customization services. Suppliers with in-house software engineering teams can implement specific mean calculation methods (arithmetic, geometric, harmonic) and adjust sampling intervals, data buffering, and output formatting per client requirements.

What is the typical lead time for customized calculating devices?

Standard devices have lead times of 15–30 days. Custom firmware integration extends timelines by 20–40 days depending on complexity. Prototypes for validation typically ship within 3–5 weeks after specification finalization.

Do these devices support other statistical functions?

Mid-to-high-end models often include standard deviation, median, minimum/maximum tracking, and variance calculations. Confirm multi-function support during technical specification review. Some suppliers provide SDKs or configuration software for end-user programmability.

Is there a minimum order quantity (MOQ)?

MOQ varies by supplier and customization level. Standard devices may have MOQs as low as 10 units. Fully customized firmware or hardware designs typically require MOQs of 500–1,000 units to justify setup costs. Prototype batches under 50 units are often available at premium pricing.

How to verify calculation accuracy before procurement?

Request test reports using standardized input sequences. Conduct side-by-side comparisons with reference software (e.g., MATLAB, Excel, or Python NumPy). For critical applications, perform independent lab validation of output precision, especially for floating-point operations and large data sets.