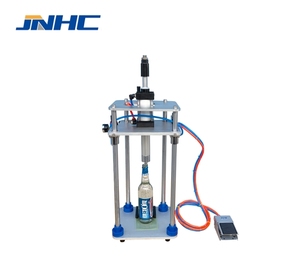

Capping Machines

Top sponsor listing

Top sponsor listing

About capping machines

Where to Find Capping Machines Suppliers?

China remains the global hub for capping machine manufacturing, with key production clusters in Zhejiang, Guangdong, and Shandong provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production. Wenzhou in Zhejiang specializes in precision engineering for semi-automatic and handheld cappers, leveraging localized stainless steel and pneumatic component suppliers. Guangzhou-based manufacturers focus on cosmetics and pharmaceutical packaging lines, integrating filling, capping, and labeling systems. Shandong’s packaging machinery cluster emphasizes automation and vacuum-sealing technologies for food and beverage applications.

The industrial ecosystems enable cost efficiencies of 20–35% compared to Western or Southeast Asian producers, driven by concentrated component sourcing, mature fabrication expertise, and streamlined logistics. Facilities typically operate within 50km of material suppliers and port hubs, reducing lead times for standard units to 15–30 days. Buyers benefit from flexible MOQs—some suppliers offer single-unit orders—while maintaining access to customization in cap size, torque settings, and integration with existing production lines.

How to Choose Capping Machines Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical & Functional Compliance

Verify compatibility with target container types (glass, PET, HDPE) and closure mechanisms (screw caps, snap lids, crimp seals). For regulated industries like pharmaceuticals or cosmetics, ensure machines meet GMP standards and are constructed from food-grade 304/316 stainless steel. CE marking is essential for European market compliance, while UL certification may be required for North American installations.

Production and Customization Capability

Assess supplier capacity through key indicators:

- Minimum factory area of 2,000m² for dedicated assembly lines

- In-house machining capabilities (CNC, welding, pneumatics)

- Proven experience with custom modifications: cap diameter range, bottle height adjustment, turntable configurations, and integration with conveyors

- Design-to-delivery cycle under 25 days for modified units

Cross-reference online revenue data and product listings to confirm consistent output and specialization in capping technology rather than general packaging equipment.

Quality Assurance and Transaction Security

Prioritize suppliers with documented quality control processes, including pre-shipment testing for torque consistency and sealing integrity. On-time delivery rates above 95% and response times under 2 hours indicate operational reliability. Use secure payment terms such as escrow or milestone-based disbursements until site acceptance testing is completed. Request sample units to validate performance against specified capping speed (units per minute) and defect rate (target: <0.5%).

What Are the Best Capping Machines Suppliers?

| Company Name | Specialization | Main Products | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Customization Options | Verified Type |

|---|---|---|---|---|---|---|---|---|

| Nantong Yuquan Machinery Technology Co., Ltd. | Integrated Packaging Lines | Filling, Labeling, Capping, Drying Equipment | US $140,000+ | 75% | ≤2h | 50% | Color, Material, Size, Logo, Packaging, Label, Graphic | Custom Manufacturer |

| Wenzhou Haizhou Import And Export Co., Ltd. | Semi-Automatic Screw Cappers | Table-top, Handheld, Vacuum, Turntable Models | US $960,000+ | 99% | ≤1h | <15% | Diameter, Size, Vacuum, Labeling, Cap Size, Logo, Plug | Custom Manufacturer |

| Guangzhou HMD Cosmetics Machinery Co., Ltd. | Cosmetic & Pharma Capping | Perfume Fillers, Vial Crimpers, Pneumatic Sealers | US $380,000+ | 97% | ≤2h | <15% | Bottle Diameter, Sprayer Type, Crimping Head, Collaring, Material, Logo | Custom Manufacturer |

| Shandong Jiahe Packaging Machinery Co., Ltd. | Vacuum & Tinplate Capping | Vacuum Sealers, Can Cappers, Filling Heads | US $290,000+ | 98% | ≤1h | <15% | Jar Sizes, Cap Diameters, Capping Speed, Machine Head, Lifting Speed | Multispecialty Supplier |

| Guangzhou Maiton Automation Packaging Equipment Co., Ltd. | Full-Automatic Desktop Systems | Auto Cap Feeders, Reagent Bottle Cappers | US $270,000+ | 95% | ≤4h | 27% | Limited (system-level customization) | Not Specified |

Performance Analysis

Wenzhou Haizhou leads in reliability with a 99% on-time delivery rate and sub-one-hour response time, supported by high online transaction volume indicating robust production throughput. Despite lower reorder rates, its extensive customization options suggest strong technical adaptability for niche applications. Nantong Yuquan stands out for customer retention (50% reorder rate), reflecting long-term satisfaction, though its 75% on-time delivery raises concerns about fulfillment consistency. Guangzhou Maiton demonstrates mid-tier performance with moderate reorder activity and responsiveness, suitable for buyers prioritizing automated desktop solutions. Shandong Jiahe excels in vacuum capping technology, combining high delivery performance (98%) with specialized head and speed adjustments critical for preserving product integrity in honey, sauces, and dairy.

FAQs

How to verify capping machine supplier reliability?

Confirm ISO 9001 certification for quality management systems. Request evidence of CE or equivalent safety compliance. Analyze verifiable delivery records, customer reviews focusing on post-installation support, and conduct virtual factory audits to assess production line organization and inventory control.

What is the typical lead time for capping machines?

Standard models ship in 10–20 days. Customized or fully automatic systems require 25–40 days depending on complexity. Add 7–14 days for international air freight or 25–45 days for sea shipment based on destination.

Do suppliers offer customization for cap types and bottle sizes?

Yes, most manufacturers provide adjustable chuck sets for cap diameters (typically 20–80mm), height-adjustable frames, and modular heads for screw, snap, or crimp closures. Advanced suppliers offer CNC-machined change parts and programmable logic controllers (PLCs) for quick format changes.

Can I request a sample or prototype before bulk ordering?

Sample units are commonly available at 30–70% of unit cost, often creditable toward full orders. Prototypes for customized configurations take 3–5 weeks to develop, including testing and validation cycles. Confirm return policies or disposal terms for trial equipment.

What are common MOQs and pricing ranges?

MOQs vary from 1 set for benchtop models to 5+ units for automated lines. Handheld cappers start at $60–$100/set; semi-automatic units range from $250–$1,200; fully automatic systems exceed $3,000. Volume discounts typically apply beyond 10 units, with potential savings of 10–15%.