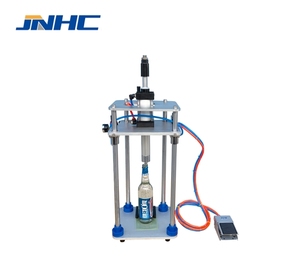

Capping Machine

Top sponsor listing

Top sponsor listing

1/10

1/10

1/3

1/3

1/25

1/25

1/3

1/3

1/10

1/10

0

0

1/6

1/6

1/18

1/18

1/15

1/15

1/14

1/14

1/19

1/19

1/13

1/13

1/3

1/3

1/10

1/10

0

0

1/8

1/8

0

0

About capping machine

Where to Find Capping Machine Suppliers?

China remains the central hub for capping machine manufacturing, with key production clusters in Zhejiang, Guangdong, and Jiangsu provinces. These regions host vertically integrated supply chains that support rapid prototyping and scalable production. Zhejiang specializes in precision packaging automation equipment, leveraging proximity to major ports like Ningbo for efficient global export logistics. Guangdong-based manufacturers benefit from advanced electronics integration capabilities, enabling smart control systems in semi-automatic and handheld models.

The industrial ecosystems in these zones offer buyers significant advantages: localized access to CNC machining, motor assembly, and sealing component suppliers reduces lead times by 20–30% compared to offshore alternatives. Average production cycles for standard capping machines range from 15 to 30 days, with express fulfillment options available for orders under 10 units. Cost efficiencies stem from consolidated material sourcing—common components such as stainless steel frames, pneumatic actuators, and torque-controlled motors are produced within 50km of most final assembly facilities.

How to Choose Capping Machine Suppliers?

Selecting reliable suppliers requires a structured evaluation across technical, operational, and transactional dimensions:

Technical Compliance

Verify adherence to international safety and performance standards. While not all suppliers list certifications explicitly, prioritize those demonstrating compliance with CE or ISO 9001 frameworks. For electric and semi-automatic models, confirm insulation protection ratings (IP54 or higher) and overload protection mechanisms. Request test reports on cycle durability—industrial-grade units should sustain 10,000+ capping operations without mechanical failure.

Production Capability Indicators

Assess supplier capacity using verifiable metrics:

- Minimum of 50 product listings across packaging machinery categories indicating diversified expertise

- In-house engineering support for customization (e.g., cap size adaptation, voltage configuration)

- On-time delivery rate exceeding 97% as an indicator of logistical reliability

- Average response time under 2 hours for real-time communication efficiency

Cross-reference online revenue data (where available) as a proxy for order volume and market validation.

Transaction Safeguards

Utilize secure payment methods tied to shipment milestones. Insist on pre-shipment inspections, especially for bulk orders, and request video demonstrations of machine operation. Evaluate after-sales service readiness, including availability of spare parts and technical documentation in English. Sample testing is strongly recommended—benchmark torque consistency and cap alignment accuracy before scaling procurement.

What Are the Best Capping Machine Suppliers?

| Company Name | Main Products (Listings) | Online Revenue | On-Time Delivery | Reorder Rate | Avg. Response | Customization Options | Product Range |

|---|---|---|---|---|---|---|---|

| Nantong Yuquan Machinery Technology Co., Ltd. | Filling Machines (230), Labeling Machines (61), Capping Machines (57) | US $110,000+ | 75% | 100% | ≤2h | Color, material, size, logo, packaging, label, graphic | 14 products |

| Dongguan Haixingda Machinery Co., Ltd. | Not specified | US $270,000+ | 99% | 15% | ≤2h | Color, material, size, logo, packaging, label, graphic | 3 products |

| Shenzhen HFYP Machinery Equipment Co., Ltd. | Sealing Machines (245), Other Machinery (537) | US $40,000+ | 100% | <15% | ≤2h | Not specified | 3 products |

| Zhejiang Haizhou Packing Machine Co., Ltd. | Filling volume, rubber cap size, air tube configurations | US $670,000+ | 99% | <15% | ≤2h | Filling volume, capping, rubber cap size, air tube | 5 products |

| Tianjin Borit International Trading Co., Ltd. | Wrapping Machines (170), Filling Machines (122), Capping Machines (25) | US $6,000+ | 100% | <15% | ≤3h | Not specified | 3 products |

Performance Analysis

Zhejiang Haizhou leads in revenue generation and offers deep customization focused on functional parameters like cap compatibility and pneumatic integration, making it suitable for specialized bottling lines. Dongguan Haixingda demonstrates strong financial scale with high on-time delivery performance, though its lower reorder rate suggests room for improvement in post-sale satisfaction. Nantong Yuquan stands out with a 100% reorder rate, indicating exceptional customer retention despite a lower on-time delivery score—this may reflect niche market alignment rather than logistical shortcomings.

Newer entrants like Shenzhen HFYP and Tianjin Borit achieve perfect on-time delivery records but have limited product specialization in capping technology. Buyers seeking long-term partnerships should prioritize suppliers with documented engineering input and multi-category packaging system experience, as they are more likely to support integrated line upgrades. Video audits of production floors can validate claims about automation levels and quality control procedures.

FAQs

How to verify capping machine supplier reliability?

Cross-check stated delivery performance against transaction history where available. Request evidence of quality management practices, such as incoming material inspection logs or final product testing protocols. Analyze customer reviews focusing on machine durability, ease of adjustment, and technical support responsiveness.

What is the average sampling timeline?

Standard sample production takes 7–14 days for manual and handheld models. Semi-automatic units with custom specifications require 18–25 days. Add 5–10 days for international air freight depending on destination region.

Can suppliers ship capping machines worldwide?

Yes, most established manufacturers manage global shipping via air or sea freight. Confirm Incoterm preferences (FOB, CIF) and ensure packaging meets international handling standards. Sea freight is cost-effective for container loads of 20+ units.

Do suppliers provide free samples?

Free samples are uncommon for industrial equipment. Most suppliers charge 30–70% of unit cost for sampling, which may be credited toward future bulk orders. Exceptions typically apply only to repeat customers or strategic partnerships.

How to initiate customization requests?

Submit detailed requirements including bottle neck diameter, cap type (screw, crown, snap-on), desired torque range, power supply (AC/DC, voltage), and integration needs (conveyor mounting, footswitch controls). Leading suppliers respond with technical drawings or 3D renderings within 72 hours.