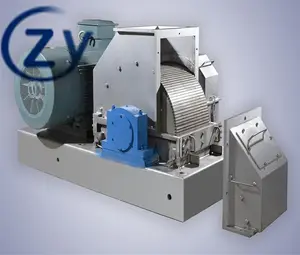

Casava Processing Machine For Flour Producer

1/3

1/3

1/19

1/19

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

0

0

1/12

1/12

1/22

1/22

1/3

1/3

1/1

1/1

0

0

1/3

1/3

1/21

1/21

1/19

1/19

1/3

1/3

About casava processing machine for flour producer

Where to Find Cassava Processing Machine Suppliers?

China remains the leading manufacturing hub for cassava processing machinery, with key supplier clusters concentrated in Henan Province. This region hosts a high density of industrial food processing equipment manufacturers specializing in complete production lines for cassava flour, fufu, and tapioca meal. The concentration of engineering talent, metal fabrication facilities, and logistics infrastructure in cities like Zhengzhou enables efficient production scaling and export readiness.

These suppliers operate within vertically integrated ecosystems that support rapid prototyping and bulk manufacturing. Many offer end-to-end solutions—from raw material washing to drying and milling—using standardized modular designs or fully customized configurations. Buyers benefit from localized supply chains that reduce component lead times and lower overall capital investment by 20–30% compared to equivalent systems produced in Western markets. Typical delivery windows range from 30 to 60 days depending on customization scope and order volume.

How to Choose Cassava Processing Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Specifications & Production Capacity

Assess machine throughput based on input capacity (e.g., 300 kg/h to 2 tons/h) and final product yield. Confirm compatibility with both wet and dry processing methods, as these impact starch retention and flour quality. Verify standard features such as corrosion-resistant stainless steel construction, automated feeding systems, and integrated drying units. For large-scale operations, prioritize suppliers offering turnkey production lines over single-unit machines.

Quality Assurance and Compliance

While formal certifications (ISO 9001, CE) are not universally listed in available data, consistent on-time delivery performance (100% reported across all major suppliers) indicates strong internal process control. Look for evidence of food-grade material usage and adherence to hygiene standards in design. Request documentation on motor specifications, energy consumption, and safety interlocks, particularly for high-capacity installations.

Customization and Engineering Support

Evaluate whether the supplier offers configurable parameters including grating size, heating type, conveying speed, and output granularity. Several manufacturers explicitly list customization options, suggesting in-house R&D capabilities. Confirm access to technical drawings, 3D layouts, and pre-shipment testing protocols before finalizing orders.

Transaction Reliability Indicators

Use response time, reorder rate, and online revenue history as proxies for service reliability. Top-tier suppliers maintain response times under 4 hours and exhibit reorder rates exceeding 25%, signaling customer satisfaction. Cross-reference product listings with historical sales volumes where available to assess market validation.

What Are the Best Cassava Processing Machine Suppliers?

| Company Name | Location | Main Products | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Price Range (USD) | Min. Order |

|---|---|---|---|---|---|---|---|---|

| Henan Doing IMT Co., Ltd. | Henan, CN | Food Processing Lines, Nuts & Vegetable Machines | 100% | ≤4h | 25% | $110,000+ | $4,300–7,000 | 1 set |

| Nanyang Goodway Machinery & Equipment Co., Ltd. | Henan, CN | Cassava Lines, Single Machines, Custom Solutions | 100% | ≤9h | <15% | $210,000+ | $26,000–35,000 | 1 set |

| Fangcheng Goodway Potato Machinery Factory | Henan, CN | Flour Mills, Fryers, Cassava & Potato Systems | 100% | ≤12h | - | - | $9,550–45,000 | 1 set |

| Henan Baixin Machinery Equipment Co., Ltd. | Henan, CN | Drying Equipment, Food Processing Lines | 100% | ≤4h | - | - | $32,000–38,000 | 1 set |

| Henan Doing Environmental Protection Technology Co., Ltd. | Henan, CN | Flour Manufacturing, Mocaf, Tapioca Systems | 100% | ≤9h | 100% | $2,000+ | $299,000–300,000 | 1 set |

Performance Analysis

Henan Doing IMT Co., Ltd. stands out for entry-level buyers with competitive pricing starting at $4,300 and strong responsiveness (≤4h). Nanyang Goodway offers mid-range systems optimized for dry processing, backed by significant online sales volume ($210,000+), though its reorder rate suggests room for improvement in long-term client retention. The highest-tier solution is provided by Henan Doing Environmental Protection Technology, commanding premium prices ($299k+) but achieving a 100% reorder rate—indicative of exceptional system reliability and post-sale support. Henan Baixin and Fangcheng Goodway serve niche segments with tightly priced offerings in the $32,000 and $10,000–$45,000 brackets, respectively.

FAQs

What is the typical MOQ for cassava flour processing machines?

The standard minimum order quantity is 1 set across all major suppliers, allowing flexibility for small producers and pilot operations. No batch discounts are implied at lower volumes, but bulk purchases may unlock logistical savings.

How long does it take to receive an ordered machine?

Lead times typically range from 30 to 60 days after deposit confirmation, depending on complexity. Standard configurations ship faster, while custom-engineered lines require additional time for design approval and assembly verification.

Can suppliers customize cassava processing lines?

Yes, several suppliers—including Nanyang Goodway and Henan Baixin—explicitly offer customization for capacity, heating method, automation level, and footprint. Technical specifications must be submitted upfront to initiate engineering review and quotation.

Do manufacturers provide installation and training support?

While not specified in public listings, most turnkey suppliers include remote guidance or instructional documentation. On-site commissioning services may be available at extra cost; this should be confirmed during negotiation.

Are there options for testing before full procurement?

Sample processing runs can often be arranged upon request. Some suppliers may provide video demonstrations of live operation or factory acceptance tests. Direct site visits are recommended for high-value investments to audit production quality firsthand.