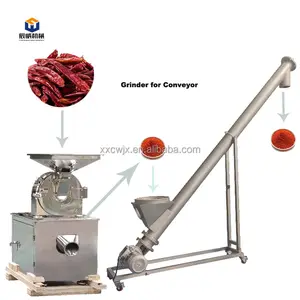

Chilli Processing Machine

About chilli processing machine

Where to Find Chilli Processing Machine Suppliers?

China remains the global epicenter for chilli processing machine manufacturing, with key supplier clusters concentrated in Henan and Zhejiang provinces. These regions host vertically integrated industrial ecosystems that support rapid prototyping, cost-efficient production, and scalable output. Henan is home to multiple food processing equipment manufacturers leveraging proximity to raw material suppliers and major logistics hubs, enabling efficient domestic and international distribution. Zhejiang-based producers, particularly around Wenzhou, specialize in precision-engineered colloid mills and wet grinding systems used in paste and sauce production.

The regional advantage lies in consolidated supply chains—steel fabrication, motor assembly, and control system integration are often located within 50km, reducing component lead times by up to 40%. This infrastructure supports typical delivery windows of 20–45 days for standard units, with customization lead times averaging 30–60 days depending on complexity. Buyers benefit from flexible MOQs (often as low as 1 set) and competitive pricing driven by localized manufacturing economies, with production costs estimated 25–35% below Western counterparts.

How to Choose Chilli Processing Machine Suppliers?

Selecting reliable partners requires systematic evaluation across technical, operational, and transactional dimensions:

Technical Compliance & Certifications

Prioritize suppliers offering CE certification or adherence to ISO 9001 quality management standards. For export to regulated markets (EU, North America), verify compliance documentation for electrical components, safety interlocks, and stainless-steel material grades (e.g., SUS304 or higher). Machines designed for continuous operation should include thermal overload protection, IP65-rated enclosures, and food-grade lubrication systems.

Production Capability Assessment

Evaluate core manufacturing competencies through the following criteria:

- Minimum factory area exceeding 3,000m² indicating capacity for full-line assembly

- In-house machining capabilities (CNC lathes, welding stations, surface polishing)

- Dedicated R&D teams supporting customization (motor power, throughput, discharge mechanisms)

- Use of modular design principles enabling scalability (batch vs. continuous feed systems)

Cross-reference online product listings with verifiable performance metrics such as on-time delivery rates (>94%) and reorder rates (>15%), which correlate with customer satisfaction and operational reliability.

Transaction Risk Mitigation

Utilize secure payment structures such as escrow services or letters of credit. Request sample testing before bulk orders—evaluate grind fineness (measured in microns), throughput consistency (kg/hr), and ease of cleaning (CIP compatibility). Confirm post-delivery support including installation guidance, spare parts availability, and remote troubleshooting access.

What Are the Best Chilli Processing Machine Suppliers?

| Company Name | Location | Verified Type | Online Revenue | On-Time Delivery | Avg. Response | Reorder Rate | Product Range | Price Range (USD) |

|---|---|---|---|---|---|---|---|---|

| GELGOOG CO., LTD | China | - | Not disclosed | Not available | ≤2h | Not available | Chilli paste, garlic, onion processing lines | $8,999–23,000 |

| Luohe Three Stones Machinery Co., Ltd. | Henan, CN | - | US $10,000+ | 94% | ≤2h | <15% | Multifunction grinders, semi-automatic sauce lines | $800–20,000 |

| Wenzhou Qiangzhong Machinery Technology Co., Ltd. | Zhejiang, CN | Custom Manufacturer | US $50,000+ | 100% | ≤6h | 16% | Wet grinding, colloid mills, spice paste systems | $500–4,500 |

| Henan Orange Industry Co.,Ltd. | Henan, CN | Custom Manufacturer | US $380,000+ | 100% | ≤2h | 18% | Automatic pepper sauce lines, tomato processing | $12,000–50,000 |

| Baixin Machinery INC | China | - | Not disclosed | Not available | ≤5h | Not available | Spice powder lines, bubble washing, drying systems | $1,600–35,000 |

Performance Analysis

Suppliers like Henan Orange Industry and Wenzhou Qiangzhong demonstrate strong reliability with 100% on-time delivery and active customization capabilities. Henan-based firms exhibit faster response times (≤2h average), aligning with regional emphasis on buyer engagement. Wenzhou Qiangzhong stands out for mid-range affordability and specialized wet grinding technology, ideal for sauce producers requiring fine particle dispersion. In contrast, GELGOOG and Baixin offer broader processing lines but lack verified transaction data, suggesting due diligence is critical. High reorder rates (16–18%) among top-tier suppliers reflect consistent build quality and after-sales service. For high-volume buyers, prioritize manufacturers with documented CE/ISO compliance and in-house engineering teams capable of adapting to specific throughput or sanitation requirements.

FAQs

How to verify chilli processing machine supplier reliability?

Validate certifications through issuing bodies and request third-party audit reports covering material traceability, weld integrity, and electrical safety. Analyze transaction history for patterns in delivery consistency and dispute resolution. Video audits of production floors can confirm claimed capabilities.

What is the typical lead time for custom machines?

Standard configurations ship in 20–30 days. Custom builds with modified motors, feed systems, or control panels require 30–60 days, depending on engineering validation and component sourcing. Rush orders may incur expedited fees.

Can suppliers provide machinery compliant with food safety standards?

Yes, reputable manufacturers use food-grade stainless steel (SUS304/316), implement smooth internal finishes to prevent bacterial retention, and design for easy disassembly and cleaning. Request FDA-compliant material declarations and CIP (Clean-in-Place) compatibility where applicable.

Do suppliers offer installation and training support?

Most custom manufacturers provide remote setup assistance via video or manuals. On-site technician deployment is typically billable and must be negotiated separately. Some include basic training in the contract; others charge per day for field engineers.

How does pricing vary across machine types?

Entry-level grinders start at $500–$1,750 for small commercial use. Mid-tier colloid mills and paste machines range from $2,500–$20,000. Fully automated production lines with washing, grinding, and packaging integration exceed $30,000. Price correlates directly with throughput (kg/hr), automation level, and material grade.