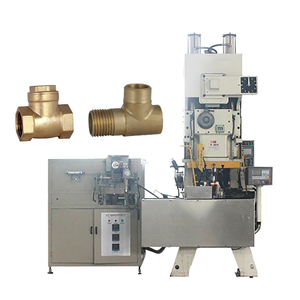

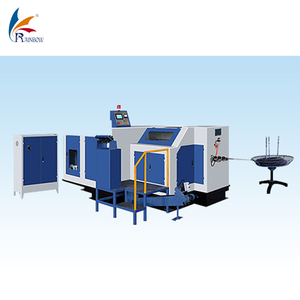

China Forging Machine Automatic Customized

1/7

1/7

CN

CN

1/3

1/3

1/28

1/28

CN

CN

1/43

1/43

1/3

1/3

0

0

1/3

1/3

1/3

1/3

1/15

1/15

1/1

1/1

1/3

1/3

1/3

1/3

1/3

1/3

1/1

1/1

1/1

1/1

1/4

1/4

1/3

1/3

1/3

1/3

1/3

1/3

About china forging machine automatic customized

Where to Find Forging Machine Suppliers in China?

China remains the global epicenter for forging machine manufacturing, with key industrial clusters concentrated in Guangdong and Liaoning provinces. These regions host vertically integrated supply chains that support both high-volume production and advanced customization of automatic forging systems. Dongguan and Foshan in Guangdong province are recognized for precision cold-forging machinery, specializing in fastener, automotive, and hardware component equipment. Meanwhile, Liaoyang in Liaoning focuses on large-scale hot forging and horizontal upsetting technologies used in heavy industry applications.

The regional ecosystems enable streamlined access to raw materials, CNC machining centers, hydraulic system integrators, and testing facilities—reducing lead times by up to 30% compared to non-specialized markets. Suppliers benefit from mature logistics networks, allowing efficient export via Shenzhen, Guangzhou, or Dalian ports. Buyers can expect localized cost advantages, with production efficiencies translating into 20–35% lower unit pricing than equivalent machines sourced from Europe or North America, particularly for customized configurations.

How to Choose Automatic Forging Machine Suppliers?

Selecting a reliable supplier requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Customization Capability

Confirm suppliers offer engineering support for custom specifications including tonnage (ranging from 60 to 650 tons), feeding automation, die design, and material compatibility (steel, titanium, aluminum alloys). Top-tier manufacturers provide CAD/CAM modeling, PLC control integration, and compliance with CE standards. Verify customization scope covering size, color, logo branding, packaging, and electrical configurations (380V/50Hz or region-specific).

Production Infrastructure Assessment

Evaluate the following benchmarks:

- Facility scale supporting dedicated R&D and assembly lines

- In-house capabilities in CNC machining, welding, and hydraulic system integration

- Minimum monthly output capacity exceeding 10 units for standard models

- On-time delivery performance ≥95% as an indicator of production stability

Cross-reference response time metrics (ideally ≤3 hours) and reorder rates to assess service reliability and customer satisfaction.

Quality Assurance & Transaction Security

Prioritize suppliers with verifiable quality management systems. While ISO 9001 certification is not explicitly stated in available data, consistent CE-marked product listings indicate adherence to European safety directives. Request documentation on material traceability, pressure testing, and load cycle validation. Utilize secure payment methods with milestone-based disbursements. Conduct pre-shipment inspections to verify machine calibration, automation function tests, and compliance with agreed specifications.

What Are the Leading Automatic Forging Machine Suppliers in China?

| Company Name | Location | Product Range | Price Range (USD) | Min. Order | On-Time Delivery | Avg. Response | Online Revenue | Reorder Rate |

|---|---|---|---|---|---|---|---|---|

| Liaoyang Pharma Machinery Imp. & Exp. Co., Ltd. | Liaoning, CN | Roll forging, horizontal upsetting, feeding systems | $8,600–$150,000 | 1 set | 71% | ≤3h | $100,000+ | 40% |

| Dongguan Yihui Hydraulic Machinery Co., Ltd. | Guangdong, CN | Cold forging presses, servo-hydraulic systems | $39,000–$85,000 | 1 piece/set | 100% | ≤2h | $240,000+ | <15% |

| Dongguan Jianlong Hydraulic Machinery Co., Ltd. | Guangdong, CN | Hydraulic forging presses, multi-tonnage systems | $24,800–$296,000 | 1 set | 100% | ≤1h | Not specified | - |

| Guangdong Yuhai Machinery Co., Ltd. | Guangdong, CN | Bolt forming, thread rolling, screw making | $1,800–$19,280 | 1 set | 100% | ≤9h | $90,000+ | <15% |

| Foshan Youcheng Fastener Mold Technology Co., Ltd. | Guangdong, CN | Cold forging, tapping, rivet and nut making | $6,100–$21,000 | 1 unit | 100% | ≤3h | Not specified | - |

Performance Analysis

Dongguan-based suppliers dominate responsiveness and delivery reliability, with three achieving 100% on-time shipment records. Dongguan Yihui and Jianlong offer mid-to-high tonnage hydraulic solutions suited for automotive and aerospace components, backed by broad price scalability. Liaoyang Pharma Machinery stands out with a 40% reorder rate—indicating strong customer retention—though its 71% on-time delivery suggests potential logistical constraints. Guangdong Yuhai and Foshan Youcheng specialize in compact, cost-effective machines for fastener production, ideal for SMEs seeking entry-level automation. Buyers requiring extensive customization should prioritize suppliers listing graphic, mold, and drawing-based modification options.

FAQs

What is the typical MOQ for automatic forging machines?

Most suppliers list a minimum order quantity of 1 set or unit, enabling low-volume procurement for testing or specialized applications. Bulk pricing typically applies at 3+ units.

How long does customization take?

Lead times range from 20 to 45 days depending on complexity. Standard modifications (logo, voltage) add 3–7 days; full mechanical redesigns (custom dies, automation integration) may extend to 60 days. Confirm timelines during technical review.

Do Chinese forging machine suppliers offer after-sales support?

Yes, leading suppliers provide remote troubleshooting, spare parts supply, and technical guidance via video or documentation. On-site installation support may be available at additional cost—clarify terms before purchase.

Are samples available for forging machines?

Full-machine samples are uncommon due to size and cost. However, suppliers often provide test reports, factory videos, or live demonstrations via video call. Some offer trial production runs using buyer-provided materials.

What shipping options are available?

Sea freight (FCL/LCL) is standard for machine exports. Suppliers typically quote FOB prices; buyers arrange final delivery. Confirm packaging standards (wooden crate, moisture protection) and insurance coverage to mitigate transit risks.