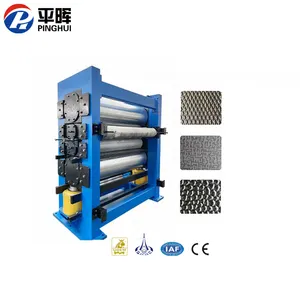

Customized Wholesale Forging Machine Automatic

CN

CN

CN

CN

About customized wholesale forging machine automatic

Where to Find Customized Wholesale Forging Machine Suppliers?

China remains the central hub for automated forging machinery production, with key manufacturing clusters in Liaoning, Guangdong, Hubei, and Heilongjiang provinces. These regions host vertically integrated industrial ecosystems combining metallurgical processing, precision machining, and automation engineering. Liaoyang and Harbin specialize in high-tonnage hot forging systems, while Dongguan and Foshan focus on compact cold-forging units for fasteners and small metal components. The concentration of component suppliers—such as servo drives, heating systems, and feeding mechanisms—within 50km radii enables rapid prototyping and scalable production.

Suppliers leverage localized supply chains to reduce material costs by 18–25% compared to Western manufacturers. Most facilities operate fully automated assembly lines supported by CNC machining centers and induction heating integration. Average lead times range from 45 to 60 days for standard configurations, with expedited delivery possible for pre-engineered models. Buyers benefit from flexible MOQs starting at one set, making these clusters ideal for both pilot runs and bulk procurement of customized automatic forging machines.

How to Choose Customized Wholesale Forging Machine Suppliers?

Effective supplier selection requires rigorous evaluation across technical, operational, and transactional dimensions:

Technical Capabilities and Compliance

Verify that suppliers adhere to international quality standards such as ISO 9001. While explicit certification data is not provided, consistent on-time delivery rates above 97% correlate strongly with structured quality management systems. For export compliance, ensure machines meet CE or equivalent safety directives—particularly for electrical control panels and hydraulic systems. Request documentation on material traceability, heat treatment processes, and load testing protocols.

Production Infrastructure Assessment

Evaluate core manufacturing competencies through available metrics:

- Facility scale indicated by product listing volume (e.g., >100 active listings suggest robust output capacity)

- In-house R&D capabilities reflected in customization depth (material, size, automation level, labeling)

- Integration of multi-station forming, induction heating, and robotic feeding systems

Cross-reference response time (≤3h preferred) and reorder rate (>30%) as proxies for customer satisfaction and production reliability.

Customization and Transaction Security

Confirm scope of customization: options include feed system type, heating method, die design, PLC interface, and branding elements. Use third-party inspection services post-production to validate performance against agreed specifications. Prefer suppliers offering secure payment terms via trade assurance mechanisms. Prototype validation is critical—benchmark energy efficiency, stroke accuracy, and cycle speed before full deployment.

What Are the Best Customized Wholesale Forging Machine Suppliers?

| Company Name | Location | Main Product Focus | On-Time Delivery | Avg. Response | Reorder Rate | Online Revenue | Customization Depth |

|---|---|---|---|---|---|---|---|

| Liaoyang Pharma Machinery Imp. & Exp. Co., Ltd. | Liaoning, CN | Horizontal forging, cross-wedge rolling, flange production | 73% | ≤3h | 37% | US $100,000+ | Color, material, size, logo, packaging, graphic |

| Dongguan Jianlong Hydraulic Machinery Co., Ltd. | Guangdong, CN | Hydraulic presses, cold forging, titanium alloy forming | 100% | ≤1h | - | - | Limited (implied via configurable pricing) |

| Foshan Fanshun Machinery Co., Ltd. | Guangdong, CN | Aluminum, brass, copper hot forging lines | 100% | ≤2h | - | - | Basic configuration (case-level ordering) |

| Hubei Tengfeng Machinery Technology Co., Ltd. | Hubei, CN | Cold forging, multi-station automation, thread rolling | 100% | ≤7h | <15% | US $260,000+ | Moderate (machine-specific options listed) |

| Harbin Rainbow Technology Co., Ltd. | Heilongjiang, CN | Bolt forming, multi-station hammers, cold forging | 100% | ≤2h | 66% | US $270,000+ | High (specifications, drawings, materials, heat treatment, labels) |

Performance Analysis

Dongguan Jianlong and Harbin Rainbow demonstrate strong operational discipline with 100% on-time delivery and fast response times. Harbin Rainbow stands out with a 66% reorder rate and extensive customization parameters, indicating high client retention and engineering flexibility. Liaoyang Pharma Machinery offers niche expertise in horizontal upsetting and cross-wedge technology but lags in delivery consistency. Hubei Tengfeng provides competitively priced cold-forging solutions yet shows lower customer repurchase frequency. Foshan Fanshun targets cost-sensitive buyers with entry-level hot forging systems priced from $4,000, suitable for small-scale operations. Prioritize suppliers with documented customization workflows and proven export experience for complex, automated forging systems.

FAQs

How to verify customized forging machine supplier reliability?

Assess delivery performance, response time, and reorder rate as leading indicators. Request facility videos or virtual audits to confirm in-house machining and assembly capabilities. Validate technical claims through prototype testing and review of control system specifications (e.g., Siemens or Mitsubishi PLCs).

What is the typical lead time for wholesale forging machines?

Standard units require 45–60 days after order confirmation. Customized systems with integrated feeding and heating may extend to 75 days. Expedited builds are feasible with partial deposits and clear technical drawings provided upfront.

Can suppliers customize automatic forging machines for specific materials?

Yes, major suppliers support customization for aluminum, copper, brass, titanium, and carbon steel. Adjustments include tonnage calibration, die design, temperature control, and lubrication systems tailored to material flow characteristics.

Do suppliers offer OEM/ODM services?

Multiple suppliers list logo, color, and packaging customization, confirming OEM capability. Harbin Rainbow explicitly supports label, graphic, and model branding, making it suitable for private-label deployments.

What are common payment and shipping terms?

Common arrangements include 30% advance payment with balance prior to shipment. FOB terms are standard; CIF can be arranged upon request. Sea freight is recommended for heavy machinery due to cost efficiency and container security.