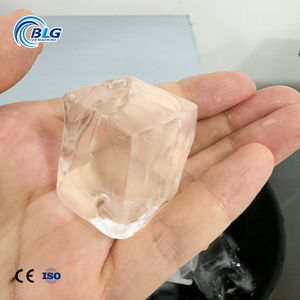

Clear Big Ice Cube Maker

1/27

1/27

1/29

1/29

1/23

1/23

1/28

1/28

1/25

1/25

1/11

1/11

1/21

1/21

1/16

1/16

1/10

1/10

1/24

1/24

1/29

1/29

About clear big ice cube maker

Where to Find Clear Big Ice Cube Maker Suppliers?

China serves as the central hub for manufacturing clear big ice cube makers, with key suppliers concentrated in industrial regions including Jiangsu, Guangdong, and Zhejiang. These provinces host vertically integrated production ecosystems that support both commercial-grade ice equipment and consumer-focused silicone molds. Nantong and Guangzhou-based manufacturers specialize in fully automated, large-capacity ice machines using directional freezing technology to produce optically clear cubes, while Shenzhen and Yiwu factories focus on cost-efficient, BPA-free silicone molds designed for home and bar use.

The regional clustering enables streamlined access to raw materials such as food-grade stainless steel, polycarbonate components, and platinum-cured silicone, reducing material lead times by 20–30%. Suppliers benefit from proximity to component vendors, logistics hubs, and certification testing centers, allowing standard order fulfillment within 15–30 days. Economies of scale and localized supply chains contribute to 25–40% lower unit costs compared to Western producers, making China a strategic sourcing destination for both bulk procurement and OEM partnerships.

How to Choose Clear Big Ice Cube Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Product & Technical Specifications

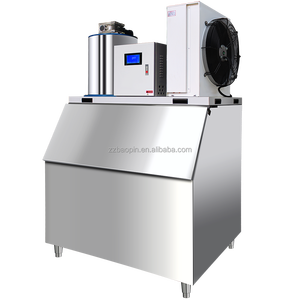

Verify whether the supplier specializes in electrical ice-making machines or passive mold solutions. Commercial units should incorporate refrigeration systems with condenser cooling, programmable logic control (PLC), and self-cleaning functions. For clarity, confirm use of slow-freeze or boiling water circulation methods. Silicone molds must be constructed from FDA-compliant, BPA-free materials capable of withstanding repeated thermal cycling.

Quality Assurance & Compliance

Prioritize suppliers with documented adherence to international standards such as ISO 9001, CE marking, and RoHS compliance—especially critical for export to EU and North American markets. Request test reports for material safety, electrical safety (if applicable), and structural durability. For food-contact products, ensure compliance with NSF or equivalent certifications.

Production & Customization Capacity

Assess customization capabilities through available options in:

- Silicone color (Pantone matching), logo embossing, and packaging design

- Mold cavity configuration (6–16 grid layouts, diamond or square shapes)

- OEM/ODM services including private labeling and custom inserts

- Industrial machine output capacity (ranging from 60kg/day to 2000lb/day models)

Cross-reference stated online revenue and reorder rates as indicators of market acceptance and reliability. Suppliers with response times under 3 hours and on-time delivery rates exceeding 95% demonstrate stronger operational discipline.

What Are the Best Clear Big Ice Cube Maker Suppliers?

| Company Name | Main Product Type | Price Range (USD) | Min. Order Quantity | On-Time Delivery | Avg. Response | Reorder Rate | Customization | Online Revenue |

|---|---|---|---|---|---|---|---|---|

| Nantong Wuding Technology Co., Ltd. | Commercial Electric Ice Makers | $500–$3,667 | 1 set | 100% | ≤3h | <15% | Limited | $60,000+ |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Silicone Ice Molds | $11.95–$20.20 | 12–100 pcs | 97% | ≤3h | 22% | Extensive | $230,000+ |

| Guangzhou Naixer Refrigeration Equipment Co., Ltd. | Commercial Ice Machines | $400–$2,970 | 1–3 sets | 94% | ≤2h | 19% | Partial | $160,000+ |

| In the trend inc. | Mixed (Ice Molds to Block Makers) | $40–$2,300 | 1–2 pcs | - | ≤9h | - | Limited | - |

| Yiwu Ziming Commodity Co., Ltd. | Silicone Ice Trays | $0.18–$0.93 | 3 pcs | 100% | ≤3h | <15% | Basic | $2,000+ |

Performance Analysis

Nantong- and Guangzhou-based suppliers dominate the commercial ice machine segment with high-output, fully automatic systems priced above $500. These manufacturers serve hospitality and beverage industries requiring consistent, large-volume clear ice production. In contrast, Shenzhen and Yiwu suppliers offer low-cost silicone molds ideal for retail and promotional distribution, with Shenzhen Benhaida standing out for its extensive customization portfolio and strong reorder rate (22%), indicating repeat buyer confidence. While Yiwu Ziming provides the lowest per-unit pricing, its minimal customization and limited transaction history suggest suitability primarily for small-scale or trial orders. Guangzhou Naixer balances affordability and responsiveness, offering sub-$600 entry-level commercial units with fast cycle times (5–15 minutes per batch).

FAQs

How to verify clear big ice cube maker supplier reliability?

Validate certifications through independent registries and request product test reports for material composition and electrical safety. Analyze supplier performance metrics such as on-time delivery rate, response time, and transaction volume. Conduct video audits of production lines when physical inspections are not feasible.

What is the typical MOQ and lead time?

MOQ varies significantly: commercial ice machines typically require 1 set (lead time: 15–25 days), while silicone molds range from 3 to 100 pieces depending on model. Mass production lead times average 20–30 days, with express options available for an additional fee.

Can suppliers provide custom branding and packaging?

Yes, especially among plastic and silicone mold manufacturers. Full OEM support—including custom colors, logos, blister packs, and instruction leaflets—is commonly offered by suppliers like Shenzhen Benhaida, often without minimum volume penalties for mid-tier orders.

Do clear ice makers require special water treatment?

Yes, optimal clarity is achieved using filtered or distilled water to minimize mineral content. Some commercial units integrate water recirculation and filtration systems to enhance transparency and reduce scaling.

Are samples available before bulk ordering?

Most suppliers offer samples at a nominal fee, which may be credited toward future orders. Sample production typically takes 5–10 days, with shipping via express courier adding 3–7 days internationally.