Clear Large Ice Cube Maker

CN

CN

Top sponsor listing

Top sponsor listing

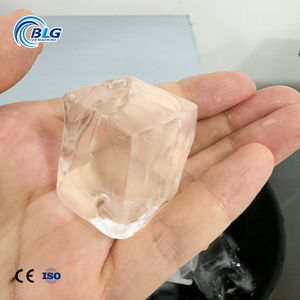

About clear large ice cube maker

Where to Find Clear Large Ice Cube Maker Suppliers?

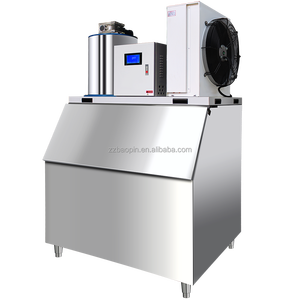

China remains the central hub for manufacturing clear large ice cube makers, with key production clusters in Guangdong, Jiangsu, and Zhejiang provinces. These regions host vertically integrated supply chains encompassing mold design, plastic injection, appliance assembly, and refrigeration engineering. Guangdong—particularly Shenzhen and Yuyao—specializes in compact, consumer-grade ice makers using advanced water filtration and directional freezing technologies to produce optically clear ice. Jiangsu-based manufacturers focus on commercial-scale units, integrating high-capacity evaporators and stainless steel construction for hospitality and bar applications.

The industrial ecosystem supports rapid prototyping and scalable production, with many suppliers operating end-to-end facilities that include R&D labs, CNC machining centers, and automated assembly lines. This integration enables lead times as short as 20–35 days for standard orders and facilitates cost efficiencies, with localized component sourcing reducing material expenses by 15–25% compared to non-Asian producers. Buyers benefit from flexible MOQs, ranging from 2 pieces for premium molds to 100+ sets for silicone trays, alongside robust export infrastructure handling LCL and FCL shipments globally.

How to Choose Clear Large Ice Cube Maker Suppliers?

Effective supplier selection requires systematic evaluation across technical, operational, and transactional dimensions:

Technical & Quality Compliance

Verify adherence to international safety and environmental standards such as CE, RoHS, and ISO 9001. For food-contact components, ensure materials are BPA-free and comply with FDA or EU 10/2011 regulations. Request test reports for durability (e.g., freeze-thaw cycle resistance) and optical clarity performance under controlled conditions.

Production Capability Assessment

Evaluate core manufacturing competencies:

- Facility size exceeding 3,000m² indicating scalable output

- In-house mold design and vacuum sealing capabilities for clarity optimization

- Monthly production capacity of at least 10,000 units for reliable fulfillment

- Dedicated quality control teams conducting pre-shipment inspections (PSI)

Cross-reference online revenue metrics and on-time delivery rates—target suppliers with ≥94% punctuality and response times under 5 hours to ensure responsiveness during order cycles.

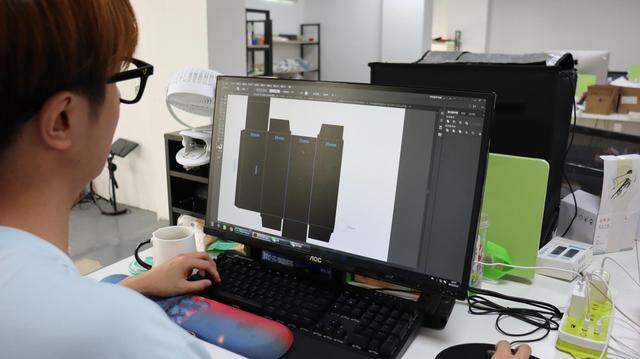

Customization & Transaction Security

Confirm available customization options including tray size (up to 2-inch cubes), color (Pantone-matched), packaging (private label, inserts), and branding (logo embossing, sleeve design). Prioritize suppliers offering third-party payment protection and documented dispute resolution procedures. Pre-production samples should be requested to validate ice clarity, ejection mechanism efficiency, and structural integrity before bulk ordering.

What Are the Best Clear Large Ice Cube Maker Suppliers?

| Company Name | Main Products (Listings) | On-Time Delivery | Response Time | Reorder Rate | Online Revenue | Customization Options |

|---|---|---|---|---|---|---|

| Yuyao Haohong Electrical Appliance Co., Ltd. | Ice Makers (130); Car Refrigerators (142) | 100% | ≤2h | <15% | US $180,000+ | Material, size, packaging, graphic |

| Shenzhen Benhaida Rubber And Plastic Products Co., Ltd. | Not specified | 97% | ≤3h | 22% | US $230,000+ | Color, shape, mold, label, logo, barcode, bundle |

| Nantong Wuding Technology Co., Ltd. | Ice Machines (382); Refrigeration Equipment (89) | 100% | ≤4h | <15% | US $60,000+ | Size, material, packaging |

| Guangzhou Naixer Refrigeration Equipment Co., Ltd. | Commercial Ice Machines (multiple models) | 94% | ≤2h | 19% | US $170,000+ | Material, size, packaging, graphic |

| Protecting Your Electronics (pye) Electronic Technology Co., Ltd. (shenzhen) | Kids Dining (63); Cake Tools (53) | 91% | ≤5h | 18% | US $130,000+ | Tray color, shape, lid, weight, vacuum sealing, logo |

Performance Analysis

Yuyao Haohong and Nantong Wuding demonstrate strong reliability with 100% on-time delivery and specialized expertise in refrigeration systems, making them suitable for consistent volume procurement. Shenzhen Benhaida stands out with a high reorder rate (22%) and extensive customization breadth, ideal for branded retail or niche market positioning. Guangzhou Naixer offers commercial-grade equipment with rapid response times, though slightly lower delivery consistency warrants closer shipment monitoring. Suppliers based in Zhejiang and Guangdong generally provide faster communication and greater flexibility in small-batch configurations, while Jiangsu manufacturers excel in durable, high-output machines for professional environments.

FAQs

How to verify clear ice maker supplier reliability?

Validate certifications through official databases and request factory audit reports or video tours confirming production lines and QC processes. Analyze transaction history, focusing on delivery consistency, customer reviews related to product clarity, and post-sale support responsiveness.

What is the typical sampling timeline?

Standard sample production takes 7–14 days, depending on complexity. Custom molds may require 20–30 days. Air shipping adds 5–10 business days internationally. Sample costs vary from $50–$300, often partially refundable upon order placement.

Can suppliers accommodate low MOQs for testing?

Yes, multiple suppliers offer MOQs as low as 2–100 pieces, especially for off-the-shelf models. Silicone tray producers typically allow smaller trial runs, while fully automated ice machine suppliers may require minimum 1-set orders.

Do manufacturers support private labeling and packaging design?

Most leading suppliers offer full OEM/ODM services, including custom box design, branded labels, user manuals, and molded-in logos. Digital proofing is commonly provided within 48 hours of artwork submission.

How to optimize logistics for ice maker imports?

For lightweight accessories (trays, molds), air freight is cost-effective for volumes under 1 CBM. Full container loads (FCL) of automated units benefit from sea freight, particularly 20’ or 40’ GP containers. Confirm Incoterms (FOB, CIF) upfront and ensure compliance with destination electrical and appliance safety regulations.